How can fresh meat be effectively packaged to extend its shelf life without losing its flavor and color? The meat chamber vacuum machine is an excellent solution. A good vacuum packaging machine can extend the shelf life can be extended by approximately 2–5 times under refrigerated conditions.

This article will analyze the indispensable role of this machine in the meat processing industry, based on its inherent characteristics, and discuss its typical market price. This will help customers who are considering purchasing the machine to be well-prepared before making their purchase.

What is a vacuum packaging machine?

A meat chamber vacuum sealer is a professional food packaging solution primarily used to remove air from vacuum bags and seal them, effectively extending the shelf life of fresh meat, poultry, seafood, and processed meat products.

By creating a low-oxygen environment, this machine effectively prevents bacterial growth, meat oxidation, and moisture loss, making it an essential piece of equipment for butcher shops, meat processing plants, restaurants, and food distribution centers.

With the growing demand for safe meat storage, longer shelf life, and export-grade packaging, vacuum packaging machines have become a standard choice in the meat industry. If you want to have a better packaging effect, please contact us for your exclusive plan.

Why do many meat businesses choose chamber vacuum packaging?

Meat products are highly sensitive to air, temperature, and contamination, and mishandling at any stage can lead to significant changes in their color and smell. Therefore, customers in the meat industry typically face the following challenges:

- Fresh and processed meats have short shelf lives, and the limited sales channels under traditional storage methods are extremely difficult to store.

- There is a high risk of spoilage and deterioration during storage and transportation. What’s more, the exposure to air accelerates spoilage due to environmental contamination.

- Ordinary packaging is prone to leaks or improper sealing, leading to negative customer feedback and damaging brand reputation.

- For export products, there are strict food safety and hygiene requirements for meat products, which are difficult to meet with ordinary packaging.

However, meat chamber vacuum machines can effectively solve these packaging and food safety problems, even for special liquids or marinated meat products, by providing stable vacuum pressure, uniform sealing effects, and reliable packaging quality.

Key advantages of meat chamber vacuum machines

- The enclosed chamber structure of this meat chamber vacuum sealing machine allows it to achieve extremely high and stable vacuum levels, ensuring maximum air removal and a perfect seal.

- Vacuum sealing performed by the vacuum sealer packaging machine significantly slows down oxidation and microbial activity, extending the shelf life of meat products by 2-5 times compared to traditional packaging methods.

- Taizy vacuum packaging machine is equipped with heating strips and a precise temperature control system, enabling a strong and completely leak-proof seal, making it ideal for fresh meat, frozen meat, and products containing moisture.

- Unlike external meat chamber vacuum machines, chamber vacuum packaging machines can safely package meats containing blood, marinades, or sauces without influencing the seal quality.

Best-selling models and their specifications

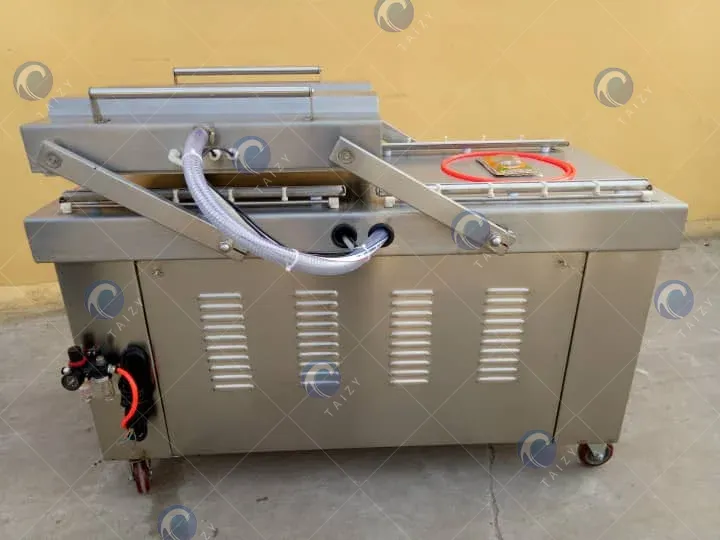

Our double-chamber vacuum packaging machine is a best-selling model, particularly popular with meat processing plants, butcher shops, central kitchens, and food export companies.

It is designed for continuous and efficient operation, which can process multiple products continuously, making it ideal for users who require stable vacuum performance and high daily output.

| Model | TZ-600 | TZ-700 | TZ-800 |

| Voltage | 380v/50hz 220v/50hz 110v/60hz | 380v/50hz 220v/50hz 110v/60hz | 380v/50hz 220v/50hz 110v/60hz |

| Pump motor power | 2.25kw | 2.25kw | 2.25kw |

| Sealing power | 1.17kw | 1.17kw | 1.17kw |

| Vacuum limit | 0.1pa | 0.1pa | 0.1pa |

| Heat seal number(Each room) | 2*2 | 2*2 | 2*2 |

| Sealing size(L*W) | 600mm*10mm | 700mm*10mm | 800mm*10mm |

| Seal to seal size | 304 stainless steel | 304 stainless steel | 304 stainless steel |

| Vacuum chamber material | 304 stainless steel | 304 stainless steel | 304 stainless steel |

| Displacement pump | 60m³/h | 60m³/h | 63m³/h |

| Vacuum chamber size | 600mm*530mm*160mm | 770mm*705mm*160mm | 880mm*705mm*160mm |

| Dimensions | 1460mm*605mm*960mm | 1645mm*730mm*960mm | 1900mm*730mm*960mm |

| Weight | 180kg | 260kg | 300kg |

How much will it cost for the meat chamber vacuum machine?

The final price of a double-chamber vacuum packaging machine is not fixed, but rather determined by the machine specifications and the customer’s specific application needs.

The capacity and power of the meat chamber vacuum machine are major factors affecting the price. Its large-capacity industrial vacuum pumps offer faster vacuuming speeds and higher vacuum levels, which are especially important for meat and wet products.

The double-chamber vacuum packaging machine, featuring a full 304 stainless steel chamber and lid, meets food-grade hygiene standards and is more durable in humid processing environments, which also impacts the overall cost, making it more expensive than machines made with ordinary materials.

Other optional configurations, such as customized chamber sizes, special sealing configurations, export packaging, or spare parts, will also significantly impact the overall cost.

If you are interested in this meat chamber vacuum machine, don’t hesitate to contact us! We will provide you with the latest price and the best service!

In addition, we also offer other packaging options for your meat products or snacks: Flow Wrap Packaging Machine, Multi-head Weighing Packaging Machine.