In short, the chips packaging machine is an all-around packager that has many functions. For example measuring, feeding, filling, bag making, inflation, and date printing.

In addition, vertical design, equipped with a 10 heads combination weigher, a packaging speed of 20-80bags/min, and a variety of packaging materials. It perfectly solves the problem of fragile potato chips during the packaging process.

Application of Chips Packaging Machine

Chips packaging machine or potato chip packaging machine is suitable to package fragile materials demanding high accuracy, such as puffed food, crispy rice, jelly, candy, pistachio, apple slices, dumpling, chocolate, pet food, small hardware, medicine, etc.

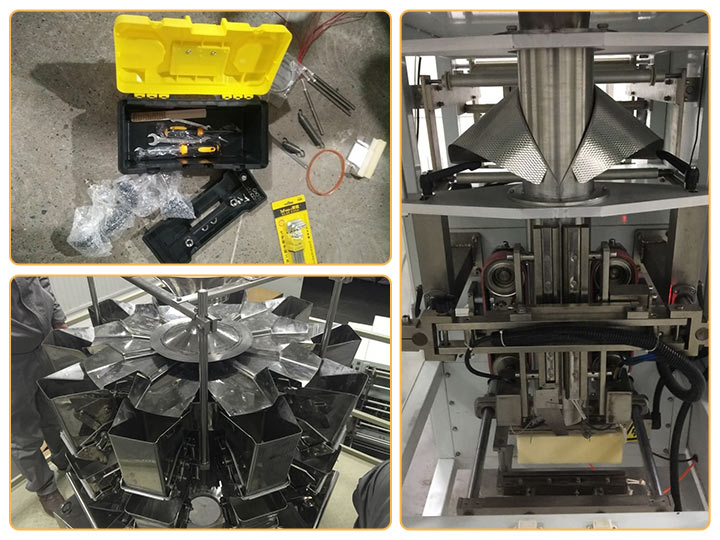

Chips Packaging Machine’s Combined Parts

SLY-420 basic machine

Generally, the machine completes the whole procedure of feeding, measuring, bagging, date printing, charging, finished product out-putting automatically. Besides, it has high accuracy, high efficiency without crashing the materials.

| Model | SLY-420 |

| Bag size | L80-300 W80-200mm |

| Packing speed | 20-80bags/min |

| voltage | AC220v.50-60HZ,3.0Kw |

| Compressed air consumption | 6-8kg/m2,0.15m3/min |

| weight | 500kg |

| size | L1650*W1300*H1700mm |

10 heads combination weigher

Firstly, stable operation, superior cost performance, best sales; Secondly, simple operation, touch screen controller with different language display; Computer calculation to select the best weight combination, which is better than manual weighing; Weighing hoppers can be set to discharge materials in order to effectively prevent material blockage; Finally, pre-store 99 sets of product parameters to meet the needs of various parameter programs.

| Name | 10 heads combination weigher |

| Model | TH-D10 |

| Generation system | 2.5 generation |

| Weighing scale | 10g~3,000g |

| Weighing accuracy | ±0.5~2g |

| Maximum speed | 70weighings/min |

| Power supply | 220V, 50HZ, 1.5KW |

| Hopper capacity | 2.5L |

| Display | 10.4 inch touch screen |

Z type bucket elevator

The conveyor is applicable for vertical lifting of grain material in departments such as corn, food, fodder, and chemical industry, etc. Besides, for the lifting machine, the hopper is driven by the chains to lift. What’s more, it’s used for vertical feeding of grain or small block material and large lifting quantity and highness.

| Highness of lifting | 3m-10m |

| Speed of lifting | 0-17m/min |

| Lifting quantity | 5.5cubic meter/hour |

| Power | 550w/380v |

Vibration type feeder

Firstly, the parts contacting with food are made of stainless steel 304; Then, supported with a non-grade adjuster to regulate the feeding quantity. In addition, it sends the material from the storage to the material conveyor through vibration.

| Lifting height | 0.8m-1.5m |

| Lifting capacity | 1 cubic meter/hour |

| Feeding speed | 30m/min |

| Dimension | 2110x340x500mm |

| Voltage | 220V/45W |

Main features of the whole machine

- Firstly, using an intelligent temperature controller, accurate temperature control: the packaging and sealing are beautiful and flat.

- Secondly, using PLC to control the private server motor double pull film structure, the wind and position adopt the motor automatic correction device, the super large display touch screen constitutes the drive control core; Besides, it maximizes the control accuracy, reliability, and intelligence of the whole machine.

- Then, the potato chip packaging machine and metering configuration can automatically complete all the packaging processes of metering, feeding, bag filling, inflation and date printing, and automatically complete counting.

- Next, there is a fault display system to help troubleshoot in time.

- Last, pillow-shaped bags, well-punched bags, etc. can be made according to customer needs.

Machine’s Bag Sealing Display

There is a box bag, stand bag, stand bag with a hole, strip bag, serial bag, pillow bag with a hole, and three sides seal.

Optional Equipment of Chips Packing Machine

Measuring cup type measurement, spiral type measurement, electronic automatic measurement, combination weigher.

Available Packaging Materials

OPP/PE, PET/VM, PET/PE, OPP/CPP, and other composite heat sealing materials.