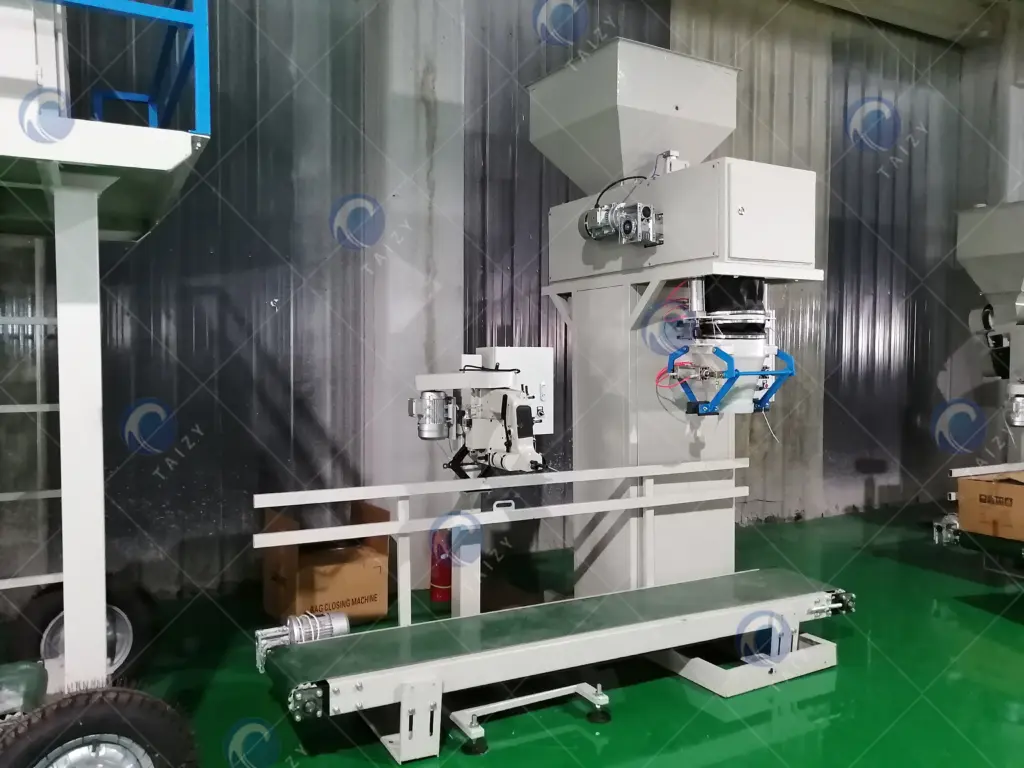

Our newly launched pet food packaging machine is an intelligent quantitative packaging solution designed specifically for materials such as dog food, cat food, fish feed, and other granular pet foods.

It integrates advanced weighing, conveying, bagging, and computer control technologies. It has a weighing range of 5-50kg and a packaging speed of up to 5 bags/minute, making it suitable for bulk packaging of pet food.

Main features of Taizy pet food pellet packaging machine

- The entire packaging machine for pet food utilizes an electrostatic powder coating production process. Compared to traditional spray painting, this process offers superior corrosion resistance, rust prevention, and oxidation resistance, resulting in a longer service life in dusty or humid feed production environments.

- Its main drive system utilizes advanced variable frequency technology to precisely control the motor speed during the feeding and weighing processes. This effectively improves weighing accuracy, especially for materials with uneven particle sizes, and results in lower operating noise and reduced vibration.

- In addition, the pet food packaging machine integrates infrared sensors and servo-controlled feeding technology to optimize the material conveying process. It not only precisely controls the feeding speed and quantity but also automatically adjusts based on real-time weighing data.

Why is this pet food bagging machine suitable for large-scale pet food packaging?

1. This pet food packaging machine is designed for continuous industrial operation, suitable for stable and continuous running during long production shifts. Its exceptional stability allows the machine to operate for extended periods without frequent shutdowns, thus ensuring consistent daily output:

- Its robust mechanical structure ensures even load distribution,

- The variable frequency drive (VFD) enables smooth, low-impact operation, reducing vibration and mechanical wear to some extent.

2. In large-scale production, even minor weighing errors can lead to significant material loss over time. This equipment, through multiple upgrades, ensures high accuracy through the following features:

- Independent suspension weighing sensors to ensure stable signal transmission

- A digital frequency control system with strong anti-interference capabilities

- Automatic error compensation and correction functions

Therefore, each packaging bag meets the required weight range, helping large pet food manufacturers reduce overfilling costs and maintain product consistency.

3. The intelligent control system for this pet food packaging machine assembly can improve production management efficiency by at least 30%. Its integrated computer control system automatically records:

- Shift production output

- Daily production output

- Cumulative total production output

This level of automation reduces reliance on manual record-keeping and minimizes human error. It also helps large factories achieve real-time production monitoring, enabling more accurate capacity planning and cost control.

4. It has a wide range of applications and supports various granular pet food materials of different particle sizes, as well as different bag materials. This adaptability allows manufacturers to increase production without changing equipment, making it highly suitable for various production lines.

Technical parameters of this pet food packaging machine

| Model | TH-25 |

| Weighing range | 5–50 kg |

| Packaging speed | 3–4 bags/minute |

| Dimensions | 2000 × 800 × 2500 mm |

| Power supply | 2.2 kW |

This configuration meets the common packaging needs of pet food manufacturers for 5–50 kg bags. If you require customization for local voltage or have other requirements, please contact us for consultation. Taizy provides comprehensive, customized services.

If you would like to mix different flavors of dog food, we also offer precision packaging machines: Automatic Quantitative Packaging Machine. This machine supports categorized quantitative packaging, making it ideal for packaging various flavors of pet food or pet treats.

Important information before purchasing pet food packaging machine

Pet food packaging is significantly affected by differences in material characteristics, packaging bag types, production capacity, and factory layout, which in turn impact weighing accuracy, packaging efficiency, and the long-term stability of the equipment.

Therefore, choosing the most suitable solution before purchasing a pet food packaging machine is crucial. The characteristics of pet food ingredients vary significantly in terms of particle size and moisture content, depending on the formulation and processing methods.

- Particle size greatly affects the feeding method. For example, large particles require stable gravity feeding, while smaller particles may require more precise screw feeding to avoid overfeeding.

- Furthermore, high-moisture pet food tends to clump together, affecting material flow and weighing accuracy. Therefore, understanding the moisture content helps engineers adjust hopper design, feeding speed, and vibration settings.

The types of pet food packaging bags vary depending on the market and distribution channels. Since the machine also involves sealing, understanding the length and width of the bag, the size of the bag opening, and the bag material is essential for confirming the final model.

- Bag dimensions determine the discharge height, stitching position, and conveyor belt alignment.

- Different bag materials require different clamping forces and stitching tensions.

- Mismatched bag dimensions and materials can lead to bag slippage, uneven sealing, or material spillage.

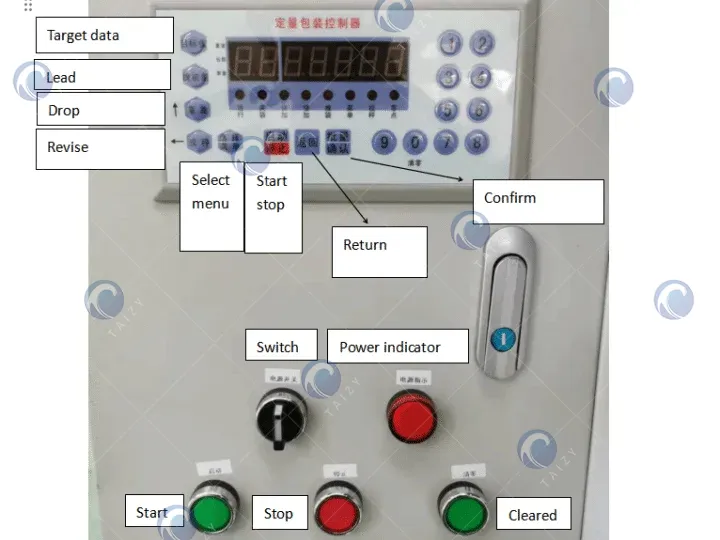

How to adjust the weight on the pet food packing machine?

Step 1: Powering on the machine

Turn on the power switch of the pet food packaging machine and wait for the system to complete the startup process.

Before making any adjustments, ensure the machine is in standby or setup mode.

Step 2: Setting the target weight

Enter the desired packaging weight on the control panel. After entering the value, click “Confirm” to save the target data. (This step is used to set the final weight of each pet food bag.)

Step 3: Pre-stop feeding control

Set the pre-stop value, which controls the machine to slow down the feeding speed when approaching the target weight.

As the weight approaches the target value, the feeding speed will decrease. The pre-stop setting prevents overfilling due to material inertia and improves the final weighing accuracy. Correct adjustment of the pre-stop value is especially important for granular pet food with a fast flow rate.

Step 4: Weight calibration

Calibration ensures weighing accuracy and should be performed after initial setup or maintenance.

Hold the “Calibration” button and hang a known standard weight on the weighing system. Enter the accurate weight value on the screen, and finally click “Confirm” to complete the calibration. The system will automatically adjust internal parameters to match the actual weight.

FAQ of pet food packing machine

What types of pet food can this packing machine handle?

It is designed for granular materials and can package: dog food pellets, cat food pellets, fish feed and aquatic feed, and other animal feed pellets.

Can one machine pack different bag weights?

This pet food packaging machine supports a wide weighing range of 5 to 50 kilograms. The operator can easily adjust the target weight through the control system.

What bag types are supported?

This machine supports common pet food packaging bags, including polypropylene woven bags and kraft paper bags.

Is the pet food packaging machine easy to operate for new workers?

This machine features a user-friendly computer control system, simple parameter settings, and automatic data recording. Operators can usually master the basic operations after a short training period, thus reducing reliance on manual labor.

If you are interested in our pet food packaging machine, please contact us. We will provide you with any information you need and a free quote.