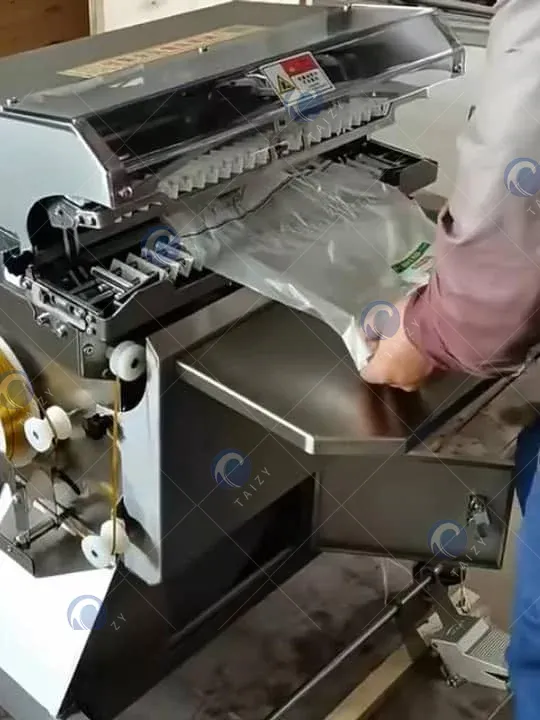

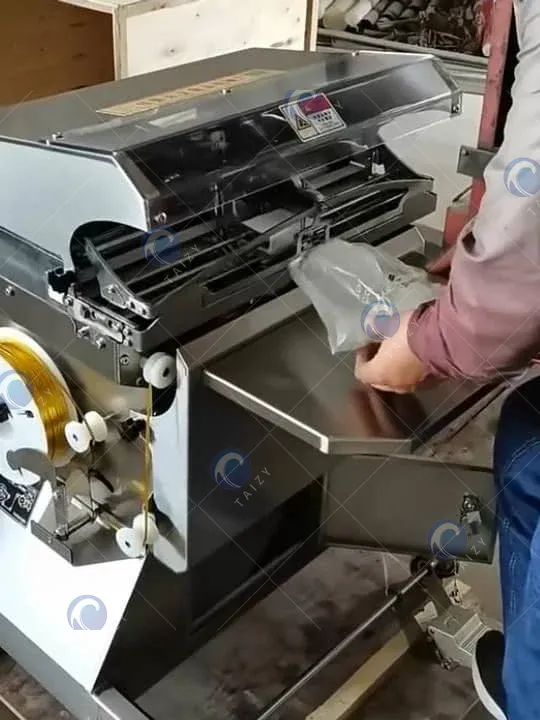

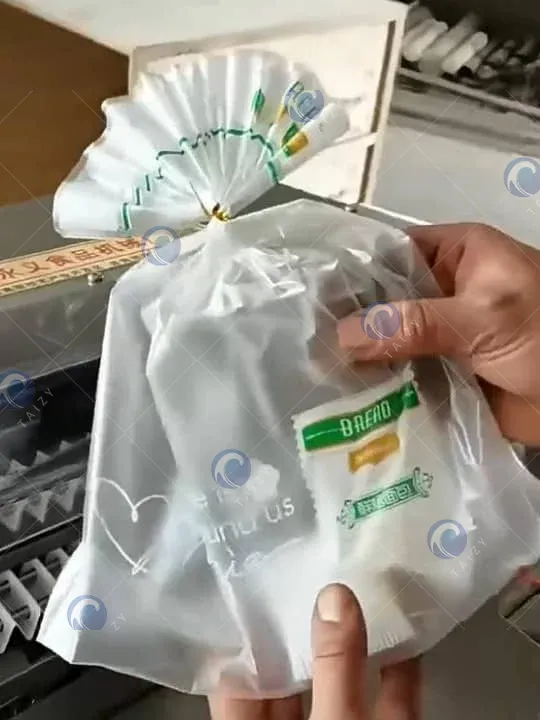

The candy gold band sealer machine automatically gathers the bag mouth, creates a uniform fan-shaped pleat, and applies a band seal/clip ring, making the bread bag packaging neat, stable, and visually appealing.

Taizy bread bag sealer machine is widely used for packaging bread, toast, pastries, candies, and baking gift bags. Its packaging speed can reach 25-50 bags/minute, perfectly meeting the needs of modern bakeries and food factories for packaging efficiency and quality.

What are the highlights of the band sealer machine?

- Taizy band sealer machine features an automatic fan-shaped folding and pleating function, capable of creating a beautiful and elegant fan shape in a second. It is highly efficient and produces a uniform appearance, making it ideal for packaging in large bakeries.

- This bag tie machine is suitable for various types of packaging bags and can be used with PP/PE film bags, printed baking packaging bags, kraft paper bags, non-woven bags, etc.

- The stainless steel structure of the band sealer machine body has a longer service life than ordinary materials. The properties of stainless steel make it not only effectively rust-proof but also easy to clean, meeting food safety requirements.

- In addition, we offer semi-automatic or fully automatic models for your selection. The semi-automatic model is more economical, while the fully automatic model can be integrated with a conveyor to achieve high-speed continuous packaging.

Key technical parameters and best-selling models

Below are the parameters for both automatic and semi-automatic models. You can choose according to your needs. If you are unsure which one suits you best, please contact Taizy customer service. Our professional customer service representatives will make recommendations based on your special needs.

Semi-automatic fan-shaped sealer LD-350

| Model | LD-350 |

| Sealing speed | 25–30 bags/min |

| Max belt width | 350 mm |

| Pleat length | 110 mm |

| Air pressure | 0.4–0.6 MPa |

| Machine weight | 65 kg |

| Dimensions | 700*700*1000 mm |

Fully automatic fan-shaped sealing machine LD-350Q

| Model | LD-350Q |

| Sealing speed | 30–50 bags/min |

| Max belt width | 350 mm |

| Pleat length | 100 mm |

| Air pressure | 0.5–0.6 MPa |

| Power supply | 220V / 50Hz |

| Motor power | 0.75 KW |

| Control system | Touch screen + PLC |

| Material | 304 Stainless Steel |

| Weight | 165 kg |

| Dimensions | 1600*1050*1400 mm |

Bag tie machine application scenarios and industries

Band sealer packing machines are suitable for tying, sealing, and binding the openings of film bags, paper bags, and non-woven bags. The fan-shaped closure design can make food products look more refined and increase their sales appeal, so it is often used in the food industry.

For example, it always applied to bread bags (sliced bread, toast, hamburger buns), pastry bags (cakes, snacks, donuts), candy bags (jelly, soft candy, hard candy, mixed snacks), and fruit and vegetable packaging bags (grapes, cherries, cherry tomatoes, and other soft fruits and vegetables) packaging.

In addition, bakeries and cake shops also use the band sealer machine to seal their daily fresh products. Especially for large-scale production, the vertical bread sealing machine has a good sealing effect, which can effectively delay the drying of food and improve the quality of shelf display.

FAQ of the band sealer machine

What types of bags can the band sealer machine handle?

It fits PP, PE film bags, kraft paper bags, non-woven bags, and candy bags with a width of 100–360 mm.

Does it require electricity?

The sealing process mainly relies on pneumatics (air pressure 0.5-0.6 MPa), but a 220V power supply is still required for the PLC control.

Can it be integrated with a packaging line?

The model LD-350Q band sealer machine can be used with a bread conveyor belt for continuous production.

What details are needed when I buy this machine?

You need to support the bag size, the type of packaging (bread, toast, candy), daily output, and power supply conditions, etc.

How to order a continuous band sealing machine?

- Step 1: Before placing an order, please specify your specific requirements for product type, packaging bag specifications (bag width, bag thickness, bag material), production requirements, and any other required additional functions.

- Step 2: Based on your needs, the supplier will recommend different types of sealing machines. You can also compare the machine’s sealing width, conveyor belt size, power requirements, and machine frame material (carbon steel/stainless steel) to select the most suitable machine.

- Step 3: When you have confirmed the machine and accessories, the supplier will issue a formal pro forma invoice. Before payment, please confirm and approve the pro forma invoice, including the price, machine model, and any additional requirements, to ensure they are correct.

- Step 4: After paying the deposit, machine production and testing will begin. The factory will use the sample bags you provide for testing before shipment and provide photos and test videos for final quality inspection.

- Step 5: After everything is confirmed, the band sealer machine will be packaged and shipped, and logistics tracking information will be also provided for you.

Taizy has professional experience in producing high-quality packaging machines for several decades and has cooperated with many international businesses around the world. If you have any problems with bag or bottle filling and sealing, Taizy would like to help you solve them!

We also provide individually packaged bread solutions. For more details, click here: Flow Wrap Packaging Machine For Candy Bread Bagging.