Taizy tea packaging machine is a fully automatic solution designed for efficient tea bag packaging. It delivers a high output of 20–60 bags per minute and can only pack 1-40g of tea, which suits bag sizes ranging from 50–80 mm in length and 45–80 mm in width.

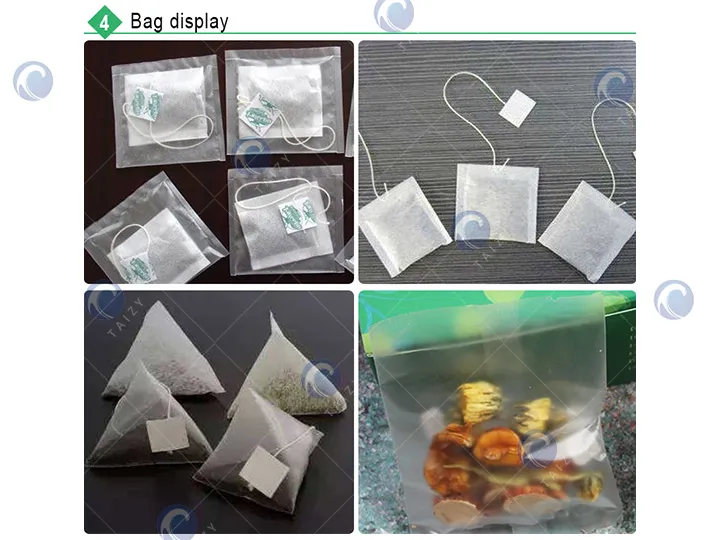

We design different machine types that offer various packaging options: integrated inner and outer packaging, inner packaging with labels, triangular nylon tape labels, etc. This tea packing machine offers three-sided and some types also provide a four-sided sealing option with aesthetically pleasing cuts and easy tearing.

Tea packaging machine’s characteristics in Taizy

- Outer wrapping paper is controlled by a stepper motor, ensuring stable bag length and precise cut positioning.

- A PID temperature controller ensures even greater precision throughout the entire process.

- The entire machine utilizes PLC control, a human-machine interface, and one-touch operation for ease of use.

- Multiple parts that come into contact with the material are made of 304 stainless steel, ensuring product hygiene and compliance with international certifications.

- Taizy tea bag packaging machine can be equipped with customized services that enable flat cutting, date printing, and easy-tear features.

- Many styles can be chosen: integrated inner and outer packaging with tags, inner packaging with labels, triangular nylon tape labels, and so on.

Application scope of tea packaging machine

This tea bag packaging machine is primarily designed for single-use, small granular, or powder products. It is ideal for packaging items such as tea dust, herbal blends, desiccants, and similar materials. Perfect for solving tea manufacturers’ packaging problems.

The machine supports a wide range of packaging materials, including tea filter paper, composite films, and non-woven fabrics, which can be formed as three-sided sealing and four-sided sealing.

Structure of the herbal tea packing machine

This illustration shows the TZ-169 tea bag packing machine with an outer envelope. The machine features a touch screen, particle turntable, hopper, scroll, packaging shaper, photo sensor, and conveyor.

Different models can produce different packaging styles to meet various needs. For instance, if you require tea bags with tags, choose a tea bag envelope packing machine equipped with a scroll for tag boards and string. Not sure which model is right for you? Feel free to contact us—we’ll help you find the perfect solution!

The different models and parameters of tea packaging machine

Type 1: inner tea bag with tag

| Type | Inner tea bag with tag |

| The sealing form | Three edge-sealing |

| Measuring range | 1-5g/bag |

| The bag size | Length 50-80mm; width 45-80mm |

| The label size | (L*W) 20*28mm/ 20*25mm / 20*20mm |

| Production capacity | 30-60bags/min |

| The input power | 220v 50hz 1.6kw |

| The weight | 380kg |

| Installation dimensions | 1250*750*1750mm |

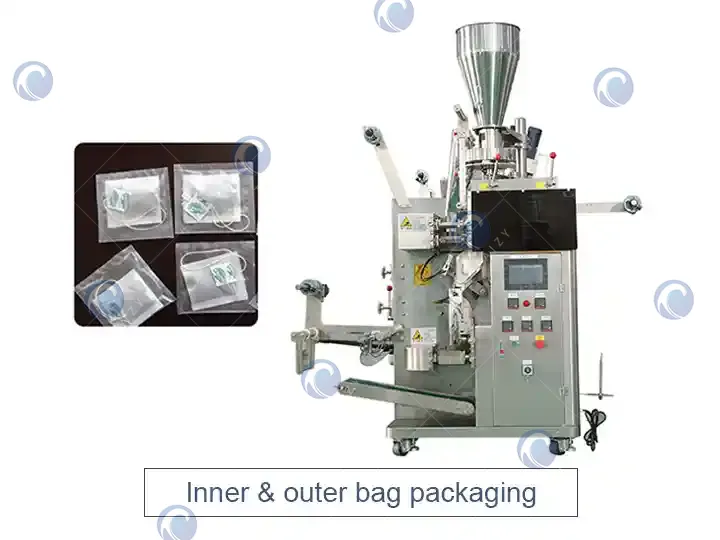

Type 2: outer&inner tea bag with tag

| Type | Outer&inner tea bag with tag |

| The sealing form | Three edge-sealing |

| Measuring range | 3-10g/bag |

| Inner bag size | Length 50-70mm; width 45-80mm |

| Outside bag size | Length 80-120mm; width 75-95mm |

| The label | Can be customized |

| Production capacity | 30-40bags/min |

| The input power | 220v 60hz 3.7kw |

| The weight | 500kg |

| Installation dimensions | 1750*700*1950mm |

Type 3: inner tea bag without tag

| Type | Inner tea bag without tag |

| The sealing form | Three-dimensional sealing |

| Measuring range | 3-10g/bag |

| Bag size | Length 50-80mm; width 45-80mm |

| Production capacity | 30-60bags/min |

| The input power | 220v 50hz 1.6kw |

| The weight | 350kg |

| Installation dimensions | 900*750*1750mm |

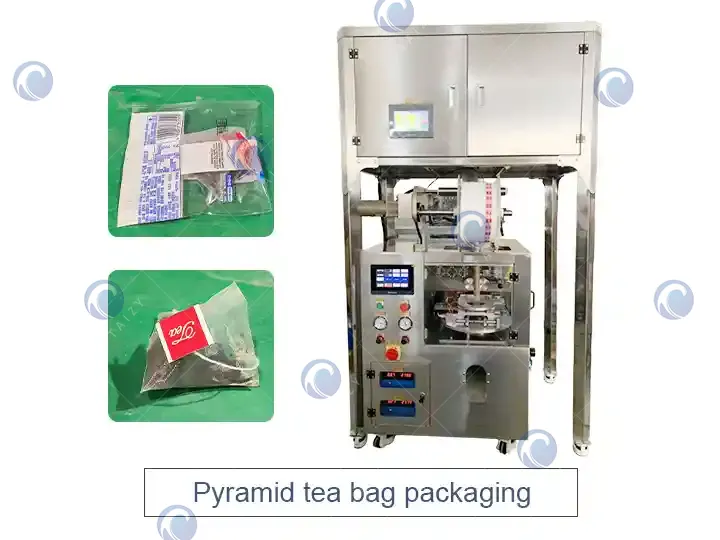

Type 4: nylon pyramid tea bag with tag

| Type | Nylon tea bag with tag |

| The sealing form | Three-dimensional sealing |

| Measuring range | 1-7g/bag |

| Bag size | Length 60-80mm; width 40-80mm |

| Production capacity | 30-50bags/min |

| The input power | 220v 50hz 3kw |

| The weight | 450kg |

| Installation dimensions | 1310*1470*2110mm |

Other types

| Type | Drip coffee bag inner & outer packing machine |

| Measuring range | 5–10g/bag |

| Inner bag size | Length 70–74mm; width 90mm |

| Outside bag size | Length 120mm; width 100mm |

| Production capacity | 20–35bags/min |

| The input power | 220v 50hz 3.7kw |

| The weight | 660kg |

| Installation dimensions | 1720*900*2270mm |

| Type | Granular packing machine |

| Measuring range | 10–40g/bag |

| Bag size | Length 40–110mm; width 30–80mm |

| Production capacity | 30–100bags/min |

| The input power | 220v 50hz 1.5kw |

| The weight | 350kg |

| Installation dimensions | 900*750*1750mm |

You can compare their packaging styles and capacities to find your ideal tea packaging machine. If you have any confusion, please let me know. Send me messages to gain more details!

Usual machine fault and maintenance

- If you notice that the vacuum level is low, it is often caused by a vacuum pump becoming dirty and clogged, or a pump that has become worn over time. To resolve this, you can start by cleaning the vacuum pump thoroughly. If the problem persists, replace the vacuum pump to restore proper performance.

- Unusual noise during operation usually indicates that the exhaust filter is clogged or that the solenoid valve may be leaking. Regularly clean or replace the exhaust filter, and inspect the solenoid valve for leaks. Replace the valve if necessary to ensure stable operation.

- If the heating system fails, the most common reasons are a damaged heater, insufficient heating oil, or a faulty transformer. In such cases, replace the heater, refill or change the heating oil, and check the heating transformer. Replace the transformer if it is no longer functioning correctly.

We will provide detailed manuals and operation videos as our after-sales service. If you want to know more information, consult me without hesitation!

With the improvement of living standards, people pay more and more attention to health preservation. Tea, as a traditional health product, is deeply loved by people. In addition, exquisite tea packaging can attract consumers’ attention and influence their psychology. Therefore, the development market of tea packaging machines will be very broad. If you want to upgrade your brand with the help of packaging, Taizy will be a good partner.