Taizy chips packaging machine is widely used in various types of puffed food, nut roasted seeds and nuts, jelly foods, plastic toys, and other granular materials or strips packaging. The packaging width is 80-200mm, and the packaging length is 80-240mm with various bagging styles: three-side seal bags, four-side seal bags, stand-up bags, handbags, etc.

In addition, it has a vertical design, equipped with a 10-head combination weigher, a packaging speed of 20-80bags/min, and a variety of packaging materials. It perfectly solves the problem of fragile potato chips during the packaging process.

Main features of the whole machine

- The potato chips packaging machine utilizes an intelligent temperature controller for precise hot-cut temperature control, ensuring a smooth and aesthetically pleasing seal.

- It also utilizes a PLC-controlled, dedicated servo motor-driven double-film-pulling mechanism and an automatic motor-driven wind position correction mechanism, which maximizes the accuracy, reliability, and intelligence of the control system.

- Then, the potato chip packaging machine with a metering configuration can automatically complete all the packaging processes of metering, feeding, bag filling, inflation, and date.

- The bag shapes can be made according to customer needs. We provide: three-side seal bags, four-side seal bags, stand-up bags, handbags, pot bags, zipper bags, composite bags, and other customizable packaging bag styles.

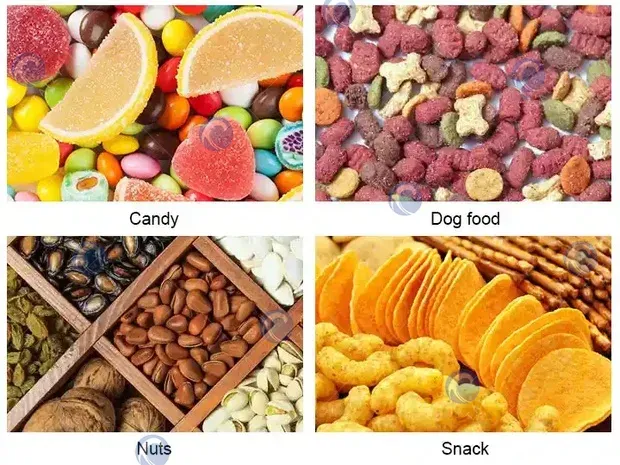

Application of chips packaging machine

Taizy chips packaging machine is suitable to package fragile materials demanding high accuracy, such as puffed food, crispy rice, jelly, candy, pistachio, apple slices, dumpling, chocolate, pet food, small hardware, medicine, etc.

It can automatically complete filling, weighing, bag making, sealing, and cutting, which is the preferred machine for snack factories, industrial parts packaging factories, and pharmaceutical packaging factories.

Parts of chips packaging machine

1. Basic packaging machine

This part uses a servo system, which can perform high-precision positioning. The packaging speed, the packaging bag length, and the cutter temperature can be changed through the PLC touch screen. Besides, the sealing and cutting method can be selected as continuous bag cutting or single bag cutting.

In addition, the packaging part is equipped with a film-pulling wheel, which is more powerful than ordinary machines and can withstand a larger packaging weight(no less than 2kg). There are three types of this vertical bagger machine: TZ-420, TZ-520, TZ-720.

| Type | TZ-420 | TZ-520 | TZ-720 |

| Bag length | 80-300mm | 80-400mm | 100-400mm |

| Bag width | 50-200mm | 80-250mm | 180-350mm |

| Max width of roll film | 420mm | 520mm | 720mm |

| Packing speed | 5-30bags/min | 5-50bags/min | 5-50bags/min |

| Measuring range | 5-1000ml | 3000ml(Max) | 6000ml(Max) |

| Air consumption | 0.65mpa | 0.65mpa | 0.65mpa |

| Gas consumption | 0.3m³/min | 0.4m³/min | 0.4m³/min |

| Power voltage | 220V | 220V/50HZ | 220V/50HZ |

| Power | 2.2KW | / | 5KW |

| Dimension | 1320mm*950mm*1360mm | 1150mm*1795mm*1650mm | 1780mm*1350mm*1950mm |

| Weight | 540Kg | 600Kg | / |

2. 10-head combination weigher

This weighing machine is ideal for weighing mixed materials (such as mixed nuts and candies), making it a top choice for large food processing plants. It can be integrated with various packaging machines, including vertical packaging machines, bag feeders, and canning machines.

Taizy weighing machine features ten hoppers, each of which uses stainless steel as its material, with individually configurable parameters, enabling precise mixing and weighing with an accuracy of ±0.3 to 1.5 g.

Besides, we also offer various customized solutions. You can choose different hopper surface treatments (polishing, patterning, etc.) according to the material characteristics (granular, powdery, fragile, sticky, etc).

| Model | 10-head combination weigher |

| Maxium weighing capacity | 1000g |

| Weighing range | 10 – 1000g |

| Weighing accuracy | ±0.3 – 1.5g |

| Weighing volume | Up to 3000cc |

| Maximum weighing speed | Up to 60weighments/min |

| Preset programs | 50types |

| Control panel | 8.4-inch touch screen (HMI) |

3. Z type bucket elevator

This conveyor of the chips packaging machine is suitable for the vertical lifting of grain material in various industries, including corn, food, fodder, and the chemical industry. The lifting machine’s hopper is driven by chains to lift.

Furthermore, it’s also used for vertical feeding of grain or small block material, allowing for large lifting quantities and high heights with its automatic feed and shut-off functions.

| Highness of lifting | 3m-10m |

| Speed of lifting | 0-17m/min |

| Lifting quantity | 5.5cubic meter/hour |

| Power | 550w/380v |

Type: It can be customized with carbon steel, plastic-spray, or stainless steel. The part in contact with food is made of food-grade plastic.

4. Vibration-type feeder

This type of feeder sends the material from the storage to the material conveyor through vibration. It features a controllable conveying speed, is constructed of PVC, and is equipped with wheels for easy mobility.

| Lifting height | 0.8m-1.5m |

| Lifting capacity | 1 cubic meter/hour |

| Feeding speed | 30m/min |

| Dimension | 2110x340x500mm |

| Voltage | 220V/45W |

Chips packaging machine’s bag sealing styles

There can be customized various packaging styles: the box bag, the stand bag, the stand bag with a hole, the strip bag, the serial bag, the pillow bag with a hole, and the three-side seal, etc.

If you have other styles of packaging want to customize, please contact me to know the additional customized service.

How to choose the right snack packaging machine?

Choosing a perfect chips packaging machine will improve your brand’s influence, because customers prefer good packaging bags when they make a decision. Here are some tips for you to choose the right snack packaging machine for your business.

- Choose the suitable machine depending on your products. Making a full understanding of your material, including whether it is fragile, whether it needs to be mixed and matched, and whether it needs to be weighed accurately.

- Determine the shape of the packaging bag, its width, length, and size. If you aren’t clear about it, please contact us. We will try our best to give you useful advice.

- Determine your production range and the required production volume. It is generally recommended to purchase a machine that is 30% higher than the actual production volume you need. This can fully ensure that your work efficiency is not affected by external factors.

Here are the complete parameters of the whole machine.

| Model | TZ-420 | TZ-520 | TZ-720 | TZ-900 | TZ-1200 |

| Film width | Max.420mm | Max.520mm | Max.720mm | Max.920mm | Max.1200mm |

| Bag length | 80-300mm | 80-350mm | 100-500mm | 100-600mm | 1000mm |

| Bag width | 60-200mm | 100-250mm | 180-350mm | 260-430mm | 290-580mm |

| Film diameter | Max.320mm | Max.320mm | Max.320mm | Max.400mm | Max.400mm |

| Packing speed | 5-60P/min | 5-60P/min | 5-55P/min | 5-20P/min | 5-20P/min |

| Measuring range | 0.15-0.5L | 2L | 4L | 1-25L | 1.5-45L |

| Power(220v 50/60HZ) | 2KW | 3KW | 3KW | 4.5KW | 5KW |

| Dimension | 1217mm*1015mm*1343mm | 1488mm*1080mm*1490mm | 1780mm*1350mm*2050mm | 2305mm*1685mm*2725mm | 2900mm*2050mm*3500mm |

If you don’t know which one is more suitable for your business, you can ask me for any advice about collecting the snack machin.