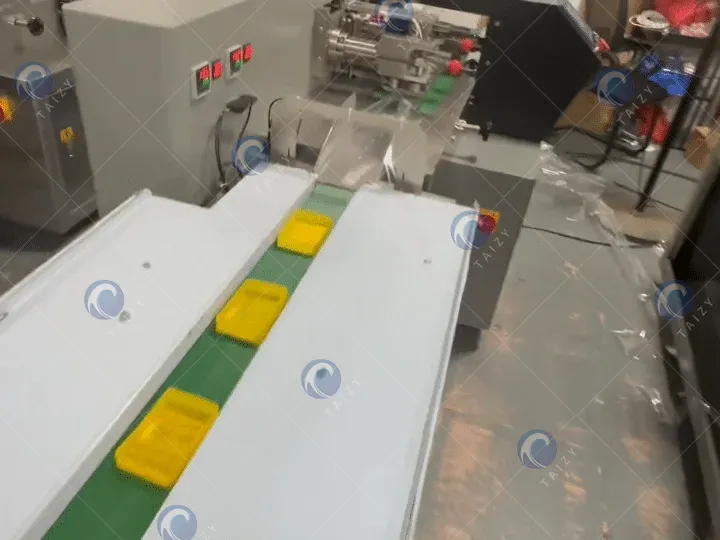

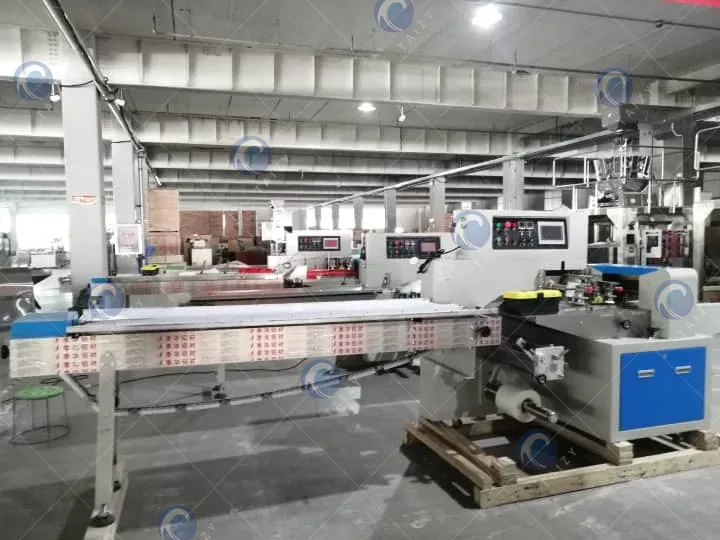

Taizy heat shrink wrap machine helps factories quickly seal packaging to create clean, protective, and aesthetically pleasing products. Our integrated system comprises a fully automatic L-shaped sealing machine and a heat-shrink tunnel, capable of sealing 20-40 boxes per minute.

In addition, it provides dust and moisture protection for products, enhancing their durability during transport. Therefore, a heat shrink wrap machine is ideal for products such as food trays, gift boxes, cosmetic boxes, stationery sets, books, sushi boxes, and hardware tool sets.

Key features of this shrink wrapping machine

- This heat shrink wrap machine is an integrated system seamlessly combining an L-shaped sealing machine and a heat shrink tunnel, completing sealing, cutting, and shrinking in a continuous process for maximum efficiency. It features automatic film feeding, waste collection, and high-speed hot air circulation.

- Its sealing blades ensure smooth and clean sealing lines, preventing film scorching and guaranteeing a superior retail appearance for the product. The circulating hot air tunnel ensures uniform heating in all directions, achieving tight glossy shrink packaging, enhancing product value.

- Taizy fully automatic shrink wrapping machine’s conveyor belt width can be adjusted. Its wide sealing frame and large tunnel size support a variety of products, including packaging boxes, food trays, books, cosmetics, and hardware kits.

- Our box shrink wrap machines feature a dedicated safety and energy-saving design with temperature protection and emergency stop functions. Additionally, its insulated tunnel structure helps reduce energy consumption while ensuring safe operation.

Structure and work principle of the heat shrink wrap machine

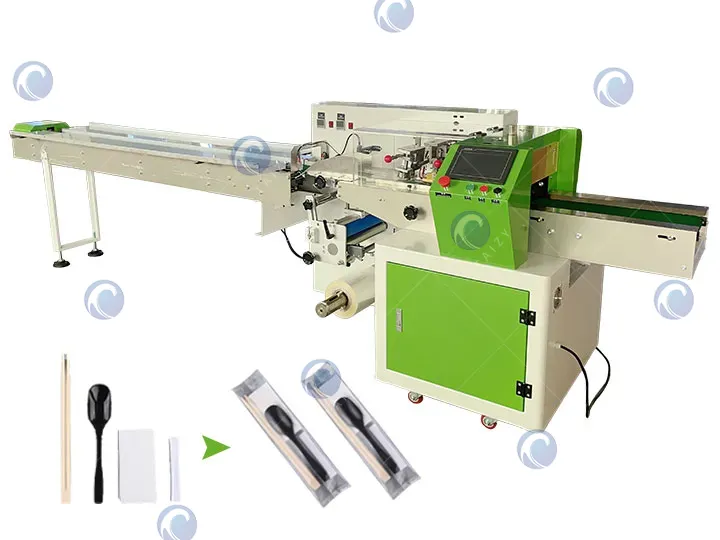

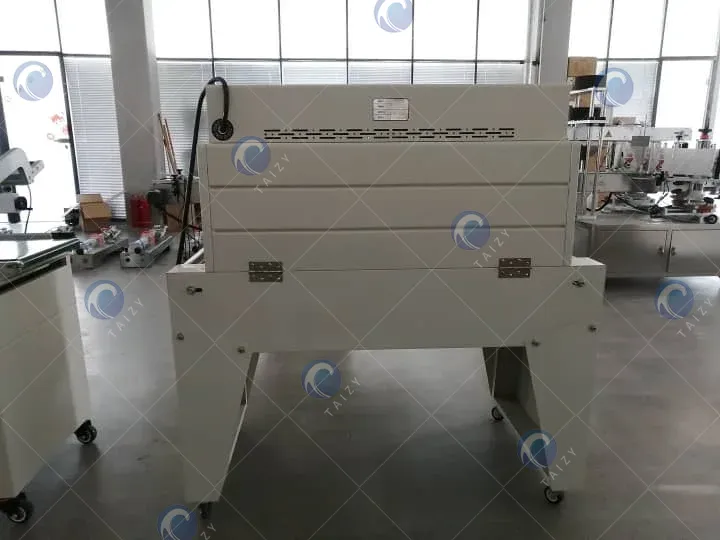

A complete automatic heat shrink wrap machine consists of two parts: an L-shaped sealing and cutting unit and a heat shrink tunnel.

1. Sealing and cutting machine

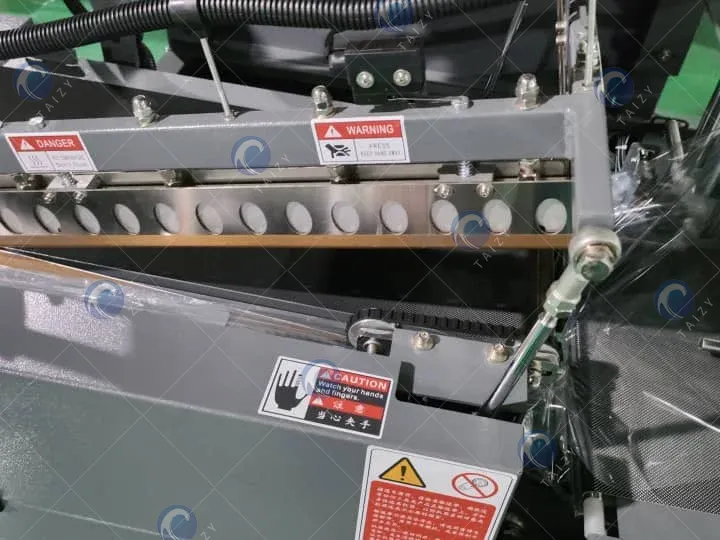

The sealing and cutting machine components are responsible for wrapping, sealing, and cutting the film.

Its structure typically includes: an L-shaped sealing blade, a film holder and film feeding system, a conveyor belt, a pressure plate/sealing frame, a waste film collection system, a conveyor belt width adjustment handle, and a control panel (temperature control, sealing time control, power switch, and emergency stop button).

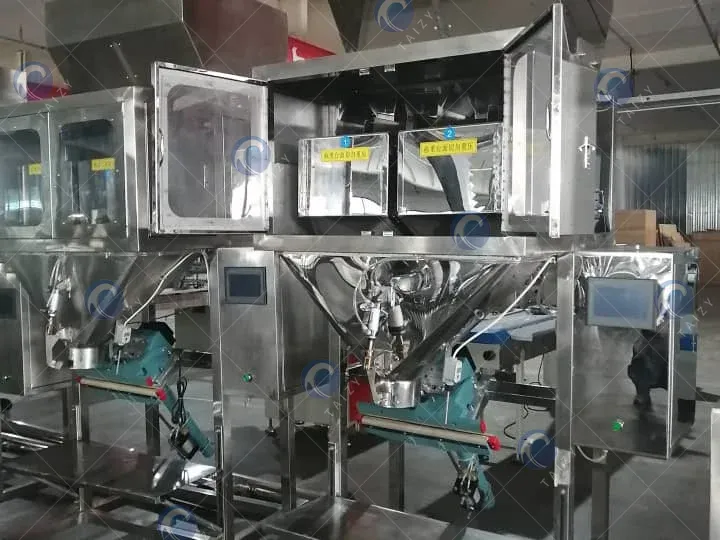

2. Heat shrink tunnel

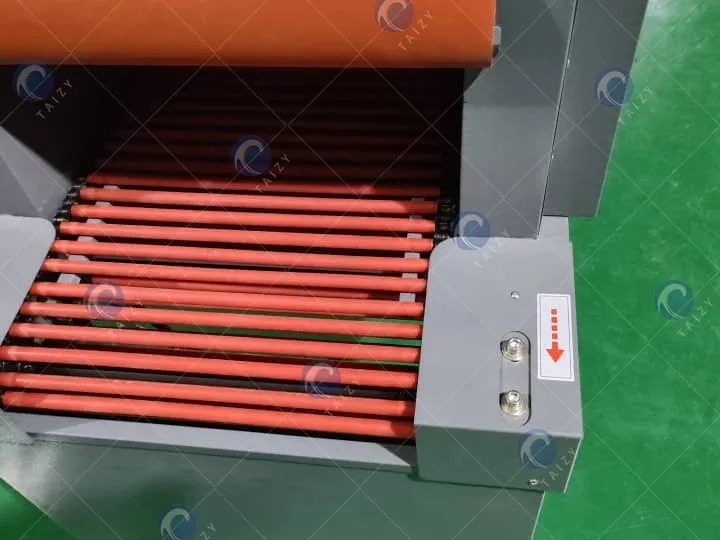

The heat shrink tunnel provides uniform and controllable heat, allowing the film to tightly shrink and wrap the product.

② Heat Shrink Tunnel (Hot Air Circulation Section)

The heat shrink tunnel provides uniform and controllable heat, allowing the film to tightly shrink and wrap the product.

Its main structural components include: high-efficiency heating tubes, a hot air circulation system, an insulated heating chamber, a heavy-duty conveyor belt, a temperature controller (adjustable from 0–300°C), and a speed controller.

This heat shrink wrap machine operates through the following three major steps:

- Step 1: Place the product on a conveyor belt and enter the sealing area. The shrink film (POF/PVC/PE) is pulled from the film roll, forming a thin film wrap around the product.

- Step 2: When the product reaches the sealing position, the L-shaped sealing blade presses downwards. The film seals tightly along the edges. Excess film is automatically cut and sent to the waste collection system.

- Step 3: The hot air circulates within the shrink tunnel, evenly heating the film, causing it to shrink and conform to the product’s shape. Then the final product emerging from the tunnel has a smooth, firm, and glossy surface with a protective shrinkage effect.

Technical specifications of our automatic heat shrink wrap machine

1. Parameters of L-bar automatic sealing machine

| Model | FQ450L | FQ550L | FQ750L |

| Power supply | 220 V 50–60 Hz | 220 V 50–60 Hz | 220 V 50–60 Hz |

| Power consumption | 1.6 kW | 1.86 kW | 2.26 kW |

| Packing speed | 15–40 bags/min | 15–40 bags/min | 15–40 bags/min |

| Air pressure requirement | 0.5 Mpa | 0.5 Mpa | 0.5 Mpa |

| Max product size | W ≤ 400 mm, H ≤ 150 mm | W ≤ 500 mm, H ≤ 150 mm | W ≤ 600 mm, H ≤ 150 mm |

| Sealing size | 570 × 470 mm | 670 × 570 mm | 870 × 770 mm |

| Machine dimensions | 1700 × 880 × 1470 mm | 1900 × 1100 × 1460 mm | 2250 × 1180 × 1475 mm |

| Packaging material | POF | POF | POF |

| Machine weight | 291 kg | 334 kg | 440 kg |

2. Parameters of the heat shrink tunnel

| Model | BSN-4522 | BSN-5530 | BSN-7535 |

| Power supply | 220–380 V 50–60 Hz | 380 V 50–60 Hz | 380 V 50–60 Hz |

| Power consumption | 15 kW | 16 kW | 24 kW |

| Tunnel chamber size | 1500 × 450 × 220 mm | 1500 × 550 × 300 mm | 1800 × 750 × 350 mm |

| Conveyor speed | 0–15 m/min | 0–16 m/min | 0–15 m/min |

| Max load capacity | 200 kg | 230 kg | 360 kg |

| Machine dimensions | 1900 × 710 × 1260 mm | 1900 × 910 × 1320 mm | 2280 × 1080 × 1640 mm |

| Packaging material | PVC / POF | PVC / POF | PVC / POF |

| Machine weight | 291 kg | 334 kg | 440 kg |

Wide applications of the shrink wrap machine heat sealer

The shrink wrapping machine is widely used in food packaging. It is commonly used for packaging ready-to-eat meals, spices, snacks, and candy boxes, providing dust and moisture protection, hygiene, and safety, as well as strong sealing to prevent the smell of spices from easily spreading.

In addition, this heat shrink wrap machine is also essential in the packaging of gift boxes. The plastic-sealed cosmetic gift boxes, skin care sets, mask boxes, and makeup sets not only prevent scratches and contamination and ensure safe transportation and handling, but also enhance the retail level and maintain the brand image.

Heat-shrink machines are also widely used in the packaging of printed materials. Plastic-sealed books and magazines can effectively reduce paper curling and also prevent dust, moisture, insects, and pests.

How to choose the right heat shrink wrap machine?

Choosing the right machine involves many factors. How can you meet packaging needs while minimizing costs? The following points are crucial to consider when selecting the best shrink wrap machine.

- First, consider the type and size of the product to be packaged. If you need to package small boxes, books, cosmetics, small electronic items, or food trays, then a medium-sized sealing and cutting machine and a medium-sized shrink oven will suffice.

- Choose the level of automation based on your packaging capacity requirements. For small packaging volumes, a semi-automatic machine is suitable. But for large-volume continuous production or assembly line operations, a fully automatic shrink wrapping machine is a more efficient choice.

Why choose our heat-shrink L-bar sealer machine?

- With 40 years of machinery manufacturing, we ensure that every heat shrink wrap machine undergoes rigorous quality control. This long-accumulated experience enables us to provide stable, durable, and efficient machines that maintain superior performance.

- Taizy machines are designed specifically to meet the actual needs of factories, which not only feature automatic film feeding and waste collection, but also allow for independent adjustment of the conveyor belt width. It makes the machine suitable for both novice and experienced operators.

- In addition, Taizy provides comprehensive technical and after-sales services, including online installation guidance and long-term maintenance support. Our professional service team will also help customers use the equipment with peace of mind.

- We offer factory-direct prices, eliminating middlemen and their markups. Every quotation is clear, detailed, and transparent. Our customers can obtain high-quality machinery and equipment, along with comprehensive and professional purchasing services, at fair and competitive prices.

Contact us to gain the latest quota and the product list of our heat shrink wrap machine! Choose Taizy as your reliable packaging machinery supplier! We also provide other packaging solutions. Click the link to know more: Sauce Filling Machine, Candy Bread Bagging Equipment, etc.