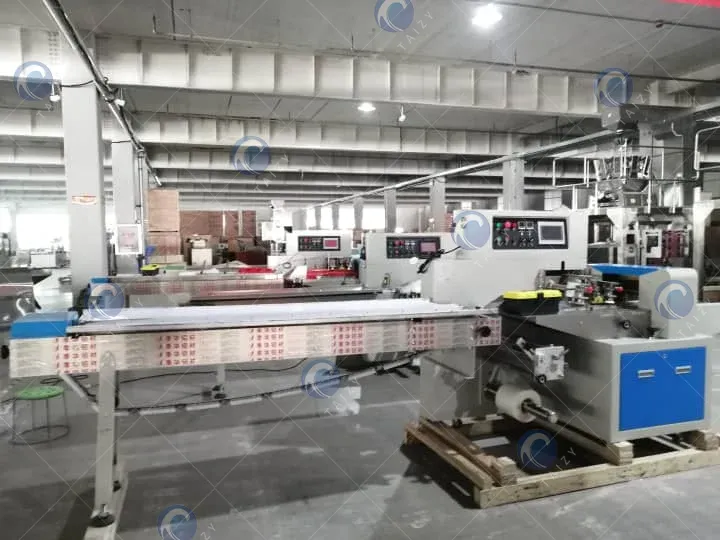

How to hygienically and quickly package solid personal care products such as soap? Taizy helped a fragrance manufacturing factory in the UAE solve its fully automated packaging problems. After being put into use, the packaging performance was upgraded, and the packaging speed increased by 50%.

Soap packaging solutions project background

A contract manufacturing factory located in the United Arab Emirates, known for producing perfumes, personal care, and home care products, is now expanding its production line to include solid soaps.

To fully implement automated production and packaging, the local production team decided to invest in an automatic packaging machine to handle soap packaging, replacing manual packaging and improving production efficiency.

Customers’ real needs of the flow pack machine

During their communication with our sales team, the customer raised the following key requirements:

- Due to strong and continuous growth in contract manufacturing orders, they require a highly efficient automated packaging machine to support large-scale production.

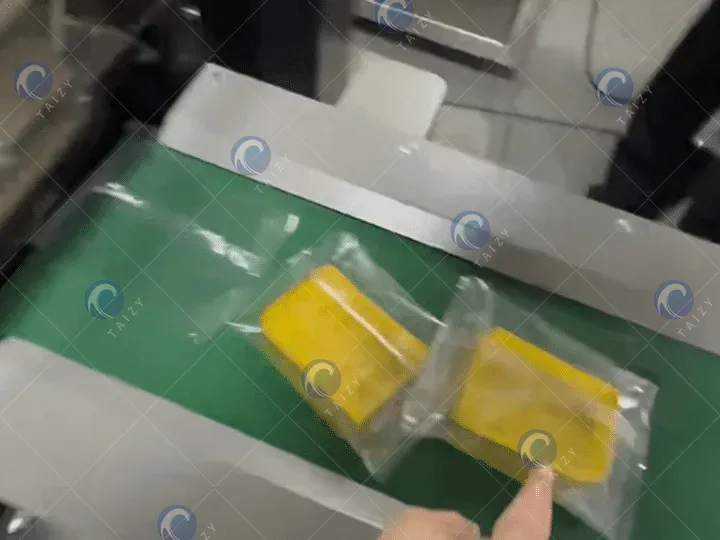

- The sealing quality must be clean, consistent, and professional, with a defect rate below 1%, and no sticking or incomplete seals are acceptable.

- The machine needs to have flexible adjustment capabilities to accommodate different sizes of soap bars without requiring complex mechanical modifications.

- A built-in time and date printing function is required to ensure batch traceability and compliance with market labeling standards.

- The flow pack machine must have a stable mechanical structure and durable components to ensure long-term continuous operation.

- It must be compatible with the local 220V industrial power supply for seamless integration into the existing production line.

Final soap packaging machine recommendation

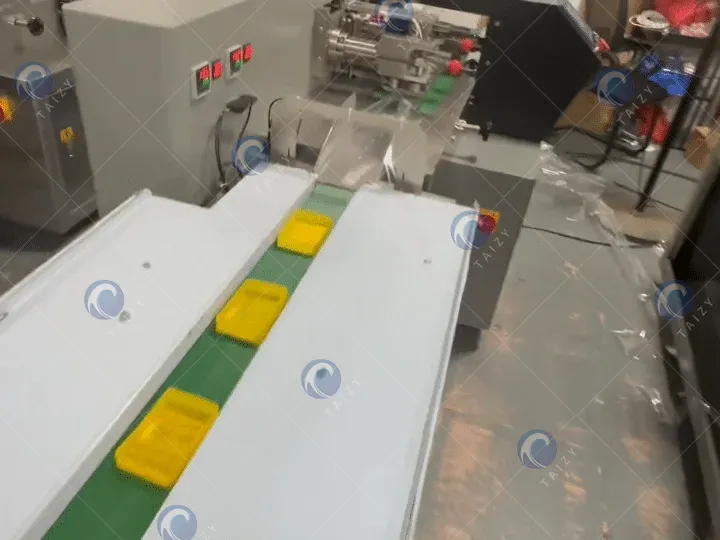

After evaluating their production needs, our customer selected the TZ-350 automatic flow pack machine as the ideal solution for soap packaging.

| Machine | Parameters |

soap flow pack machine | Parameter: specification Model: TZ-350 Power supply: 220v, 50Hz Power consumption: 2.6 kW Packaging speed: 40–230 bags/minute Bag length: unlimited Bag width: 50–160 mm Packaging height: ≤ 60 mm Maximum film width: 350 mm Machine weight: 900 kg Machine dimensions: 4020 × 745 × 1450 mm Optional features: integrated time printing function |

In subsequent feedback, the customer expressed high satisfaction with the overall performance of the equipment. The packaging system operates smoothly and quickly, supporting high-volume continuous packaging while maintaining consistent sealing quality and a professional product appearance.

If you are also facing similar packaging problems, feel free to contact Taizy for customized solutions.