The vacuum packaging machine effectively removes air from the package, helping to maintain product freshness. Taizy provides a wide range of vacuum packaging solutions suitable for sealing sauces, meat, vegetables, rice, clothing, and more. Our machines are made of SUS404 stainless steel, ensuring high food safety standards for processing factories.

We also offer extensive customization options, such as date printing and nitrogen flushing, to meet different packaging needs. The main consumables include sealing strips and vacuum pump oil, both inexpensive and easy to replace, making machine maintenance more convenient and cost-effective.

Vacuum sealer chamber machine’s main features

- With food-grade SUS304 stainless steel construction and internationally advanced sealing technology, our vacuum chamber sealer ensures both safety and durability.

- This vacuum sealer packaging machine delivers high efficiency, energy savings, and strong sealing reliability that global customers can trust.

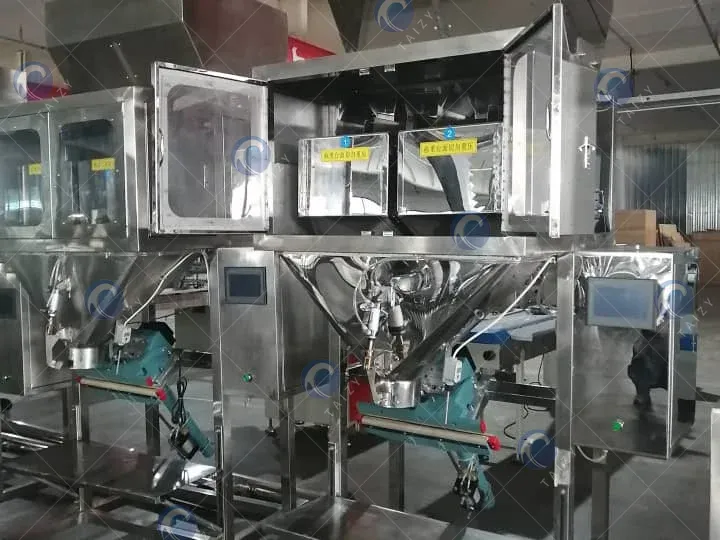

- To meet different production needs, Taizy offers a wide range of models—single-chamber, double-chamber, and vertical types—ideal for everything from daily small food processing to heavy-duty packaging of rice, clothing, bulk products, etc.

- Our commercial chamber vacuum sealer has compact designs for easy mobility and is equipped with imported parts, ensuring stable performance, long service life, and low maintenance costs.

Vacuum packaging machine’s application

Generally, the application areas of chamber vacuum food sealers involve food, grain, fruit, pickles, preserved fruits, chemicals, medicinal materials, electronic components, precision instruments, and rare metals. Especially suitable for tea, rice, compressed biscuits, fresh corn, meat, vegetables, eggs, etc.

For the food industries, a good food vacuum packaging machine can effectively preserve product taste and color, extend their shelf life, and prevent them from bacterial contamination.

It’s also popular in the apparel and textile industries. Large pillows and bedding can be compressed into a small size using a vacuum compressor for storage and transportation.

Some medical packaging also requires this chamber vacuum sealer to provide sterile packaging for instruments, medicines, and surgical materials.

To protect sensitive electronic and hardware components from moisture, dust, and oxidation, a vacuum packaging machine is often the best choice.

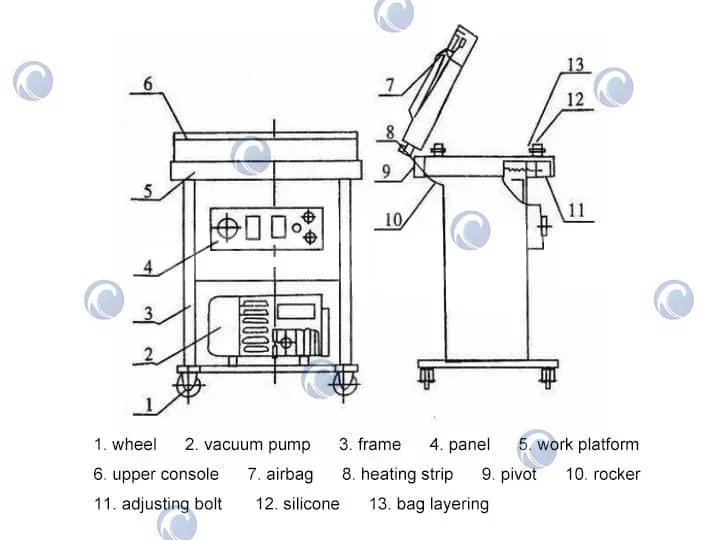

The structure of chamber vacuum sealer

It consists of 4 wheels, a vacuum pump, a frame, a panel, a work platform, an upper console, an airbag, a heating strip, a pivot, a rocker, an adjusting bolt, silicone, and bag layering.

Here are schematic diagrams of cross cross-section and front view of the single-chamber vacuum packaging machine.

Besides these parts, it is also equipped with a vacuum glass cover to facilitate easy observation of the working process and status.

The double-chamber sealer’s cover can be moved in parallel and features two working platforms. Vertical vacuum sealer chamber machines are often equipped with an additional support platform to facilitate the placement of huge or heavy products.

The vacuum packaging machine’s models and parameters

Single chamber vacuum sealer chamber machine

| Model | TZ-500 |

| Voltage | 220v/50hz |

| Vaccum pump power | 0.9kw |

| Sealing power | 0.6kw |

| Absolute pressure | 0.1pa |

| Number of sealing sttrips | 2 |

| Sealing strip size(L*W) | 500mm*10mm |

| Vacuum chamber material | 304 stainless steel |

| Vacuum cover material | Plexiglas |

| Vacuum pump | 20m³/h |

| Vacuum chamber size(L*W*H) | 525mm*520mm*130mm |

| Machine size(L*W*H) | 650mm*580mm*960mm |

| Machine weight | 80kg |

Double chamber vacuum food packaging machine

| Model | TZ-400 | TZ-500 | TZ-600 | TZ-700 | TZ-800 |

| Voltage | 380v/50hz 220v/50hz 110v/60hz | 380v/50hz 220v/50hz 110v/60hz | 380v/50hz 220v/50hz 110v/60hz | 380v/50hz 220v/50hz 110v/60hz | 380v/50hz 220v/50hz 110v/60hz |

| Pump motor power | 0.75kw | 1.5kw | 2.25kw | 2.25kw | 2.25kw |

| Sealing power | 1.17kw | 1.17kw | 1.17kw | 1.17kw | 1.17kw |

| Vacuum limit | 0.1pa | 0.1pa | 0.1pa | 0.1pa | 0.1pa |

| Heat seal number(Each room) | 4*2 | 2*2 | 2*2 | 2*2 | 2*2 |

| Sealing size(L*W) | 400mm*10mm | 500mm*10mm | 600mm*10mm | 700mm*10mm | 800mm*10mm |

| Seal to seal size | 304 stainless steel | 304 stainless steel | 304 stainless steel | 304 stainless steel | 304 stainless steel |

| Vacuum chamber material | 304 stainless steel | 304 stainless steel | 304 stainless steel | 304 stainless steel | 304 stainless steel |

| Displacement pump | 20m³/h | 40m³/h | 60m³/h | 60m³/h | 63m³/h |

| Vacuum chamber size | 445mm*500mm*45mm | 560mm*525mm*160mm | 600mm*530mm*160mm | 770mm*705mm*160mm | 880mm*705mm*160mm |

| Dimensions | 995mm*630mm*905mm | 1260mm*605mm*960mm | 1460mm*605mm*960mm | 1645mm*730mm*960mm | 1900mm*730mm*960mm |

| Weight | / | 150kg | 180kg | 260kg | 300kg |

Other types of vacuum packaging machines

We also provide two other types of machines: a vertical electric vacuum sealer packaging machine and a linear tray sealer.

Vertical vacuum packaging machine

This type of chamber vacuum sealer is designed for packaging and vacuuming clothes, pillows, rice, flour, and other things have big size or heavy weight.

Linear tray sealer

It can be used to process large batches of frozen food with trays, fresh food, sealed pharmaceutical trays, standard lunch boxes, etc. It is relatively large in size, and its packaging and vacuuming efficiency is several times that of other machines.

If you have a large demand for vacuum packaging or want to fully produce your production line, please contact me for a detailed quotation.

How does a vacuum packaging machine work?

A industrial vacuum packaging machine works by removing the air inside a package and then sealing it tightly. The process usually involves the following steps:

1. Product placement

This is an important step before actual operations. You should make sure of the size of your products, including the height, length, and width.

Then put them in the vacuum chamber or sealing area. The bag opening should completely cover the machine’s heated sealing strips, without any wrinkles or curls that can cause air leaking.

Note: If using an external chamber vacuum food sealer, the bag opening needs to fit over the vacuum nozzle, and its seal aligned with the heated strips.

2. Air evacuation processing

After the product is placed, the vacuum pump is activated to remove the air from the bag. If using a dual-chamber vacuumized food packaging machine, you can load one side of the bag while the other side is working, which significantly improves efficiency.

3. Other operations

The vacuum sealer packaging machine can be equipped with a device to inject protective gases (such as nitrogen or carbon dioxide) to preserve the freshness of fragile foods and prevent them from breaking.

It can also be equipped with a printing device to print other information, such as the production date and expiration date.

FAQ about the vacuum packaging machine

1. What is the material of the machine?

304 stainless steel, steel plate thickness 3mm, lid vacuum chamber 3mm, shell 1mm

2. What is the power mode of the machine?

It is made of electric heating

3. Do you need an air compressor?

Not needed

4. How much is the vacuum packaging machine?

Different models have different prices. But you can leave a message below, and consult customer service for details

Taizy has been engaged in the packaging industry for many years. Our products are sold all over the world, and we have even established good cooperative relationships with many companies.

If you have any other questions about this machine, please feel free to consult me.