The vakum paketleme makinesi paket içindeki havayı etkili bir şekilde uzaklaştırır, ürün tazeliğinin korunmasına yardımcı olur. Taizy, sos, et, sebze, pirinç, giysi ve daha fazlasını mühürlemek için uygun geniş bir vakum paketleme çözümleri yelpazesi sunar. Makinelerimiz SUS404 paslanmaz çelikten üretilmiştir ve işleme fabrikaları için yüksek gıda güvenliği standartlarını sağlar.

Ayrıca tarih baskısı ve azot dolumu gibi farklı paketleme ihtiyaçlarını karşılamak için kapsamlı özelleştirme seçenekleri sunuyoruz. Ana sarf malzemeleri arasında mühürleme şeritleri ve vakum pompası yağı bulunur; her ikisi de ucuzdur ve değiştirilmesi kolaydır, bu da makine bakımını daha pratik ve maliyet açısından verimli hale getirir.

Vakum kapaklı mühürleme makinesinin ana özellikleri

- Gıda sınıfı ile SUS304 paslanmaz çelik yapı ve uluslararası gelişmiş mühürleme teknolojisi ile, vakum odası mühürleyicimiz hem güvenlik hem de dayanıklılık sağlar.

- Bu vakum mühürleme paketleme makinesi yüksek verimlilik, enerji tasarrufu ve güçlü mühürleme güvenilirliği sunar; dünya çapındaki müşterilerin güvenebileceği bir üründür.

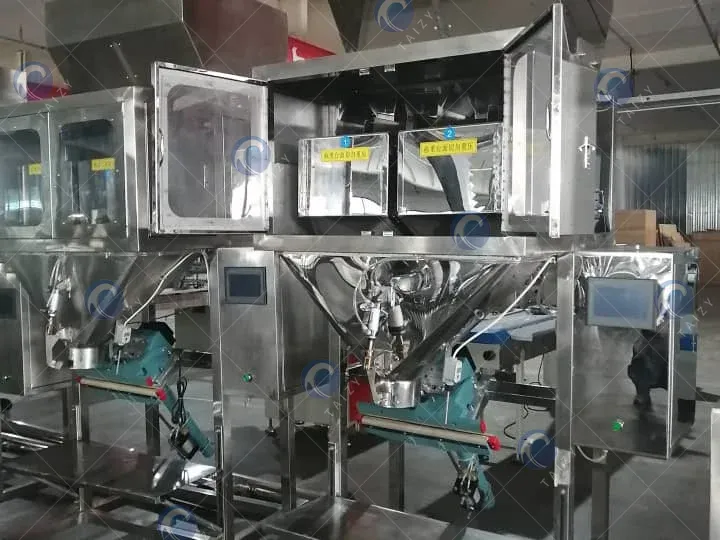

- Farklı üretim ihtiyaçlarını karşılamak için Taizy, tek hazneli, çift hazneli ve dik tipler dahil geniş bir model yelpazesi sunar—günlük küçük gıda işleme işlemlerinden pirinç, giyim, dökme ürünlerin ağır paketlemesine kadar ideal çözümler.

- Ticari hazneli vakum mühürleyicimiz taşınabilirlik için kompakt tasarımlara sahiptir ve ithal parçalarla donatılmıştır; bu da kararlı performans, uzun hizmet ömrü ve düşük bakım maliyetleri sağlar.

Vakum paketleme makinesinin uygulamaları

Genel olarak, hazneli vakum gıda mühürleyicilerin uygulama alanları arasında gıda, tahıl, meyve, turşu, konserve meyveler, kimyasallar, ilaç hammaddeleri, elektronik bileşenler, hassas aletler ve nadir metaller yer alır. Özellikle çay, pirinç, sıkıştırılmış bisküvi, taze mısır, et, sebze, yumurta vb. için uygundur.

Gıda endüstrileri için iyi bir gıda vakum paketleme makinesi ürünün tadını ve rengini etkili şekilde koruyabilir, raf ömrünü uzatabilir ve bakteriyel kontaminasyonu önleyebilir.

Ayrıca giyim ve tekstil endüstrilerinde de popülerdir. Büyük yastıklar ve yatak takımları, depolama ve nakliye için vakum kompresörü kullanılarak küçük bir boyuta sıkıştırılabilir.

Bazı tıbbi ambalajlar da aletler, ilaçlar ve cerrahi malzemeler için steril ambalaj sağlamak amacıyla bu hazneli vakum mühürleyiciyi gerektirir.

Hassas elektronik ve donanım bileşenlerini nem, toz ve oksidasyondan korumak için vakum paketleme makinesi genellikle en iyi seçenektir.

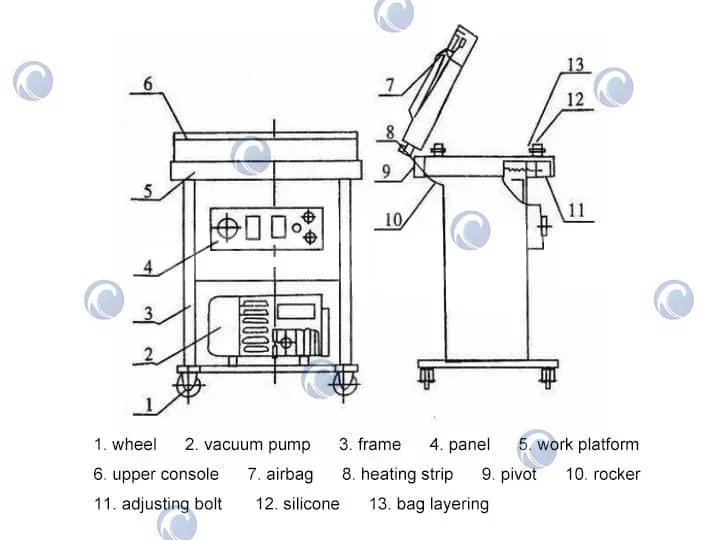

Hazneli vakum mühürleyicinin yapısı

4 tekerlek, bir vakum pompası, bir çerçeve, bir panel, bir çalışma platformu, üst bir konsol, bir hava yastığı, bir ısıtma şeridi, bir mafsal, bir salıncak, bir ayar cıvatası, silikon ve torba katmanlamasından oluşur.

İşte tek hazneli vakum paketleme makinesinin enine kesit ve ön görünüm şematik diyagramları.

Bu parçaların yanı sıra, çalışma sürecinin ve durumunun kolayca gözlemlenmesini sağlamak için bir vakum cam kapağı ile donatılmıştır.

Çift odalı mühürleyicinin kapağı paralel olarak hareket ettirilebilir ve iki çalışma platformuna sahiptir. Dikey vakum mühürleme makineleri, büyük veya ağır ürünlerin yerleştirilmesini kolaylaştırmak için genellikle ek bir destek platformu ile donatılmıştır.

Vakum paketleme makinesinin modelleri ve parametreleri

Tek odalı vakum mühürleme makinesi

| Model | TZ-500 |

| Voltaj | 220v/50hz |

| Vakum pompası gücü | 0.9kw |

| Mühürleme gücü | 0.6kw |

| Mutlak basınç | 0.1pa |

| Mühürleme şerit sayısı | 2 |

| Mühürleme şeridi boyutu(U*G) | 500mm*10mm |

| Vakum hazne malzemesi | 304 paslanmaz çelik |

| Vakum kapak malzemesi | Plexiglas |

| Vakum pompası | 20m³/h |

| Vakum hazne boyutu(U*G*Y) | 525mm*520mm*130mm |

| Makine boyutu(U*G*Y) | 650mm*580mm*960mm |

| Makine ağırlığı | 80kg |

Çift odalı vakumlu gıda paketleme makinesi

| Model | TZ-400 | TZ-500 | TZ-600 | TZ-700 | TZ-800 |

| Voltaj | 380v/50hz 220v/50hz 110v/60hz | 380v/50hz 220v/50hz 110v/60hz | 380v/50hz 220v/50hz 110v/60hz | 380v/50hz 220v/50hz 110v/60hz | 380v/50hz 220v/50hz 110v/60hz |

| Pompa motor gücü | 0.75kw | 1.5kw | 2.25kw | 2.25kw | 2.25kw |

| Mühürleme gücü | 1.17kw | 1.17kw | 1.17kw | 1.17kw | 1.17kw |

| Vakum limiti | 0.1pa | 0.1pa | 0.1pa | 0.1pa | 0.1pa |

| Isı mühürleme sayısı(Her hazne) | 4*2 | 2*2 | 2*2 | 2*2 | 2*2 |

| Mühürleme boyutu(U*G) | 400mm*10mm | 500mm*10mm | 600mm*10mm | 700mm*10mm | 800mm*10mm |

| Mühürden mühre boyutu | 304 paslanmaz çelik | 304 paslanmaz çelik | 304 paslanmaz çelik | 304 paslanmaz çelik | 304 paslanmaz çelik |

| Vakum hazne malzemesi | 304 paslanmaz çelik | 304 paslanmaz çelik | 304 paslanmaz çelik | 304 paslanmaz çelik | 304 paslanmaz çelik |

| Yer değiştirme pompası | 20m³/h | 40m³/h | 60m³/h | 60m³/h | 63m³/h |

| Vakum hazne boyutu | 445mm*500mm*45mm | 560mm*525mm*160mm | 600mm*530mm*160mm | 770mm*705mm*160mm | 880mm*705mm*160mm |

| Boyutlar | 995mm*630mm*905mm | 1260mm*605mm*960mm | 1460mm*605mm*960mm | 1645mm*730mm*960mm | 1900mm*730mm*960mm |

| Ağırlık | / | 150kg | 180kg | 260kg | 300kg |

Diğer vakum paketleme makinesi türleris

Ayrıca iki diğer makine türü sunuyoruz: dikey elektrikli vakum mühürleyici paketleme makinesi ve lineer tepsi mühürleyici.

Dikey vakum paketleme makinesi

Bu tür hazneli vakum mühürleyici, büyük boyutlu veya ağır olan giysi, yastık, pirinç, un ve diğer şeylerin paketlenmesi ve vakumlanması için tasarlanmıştır.

Lineer tepsi mühürleyici

Tepsilerle büyük partiler halinde donmuş gıdaların, taze gıdaların, mühürlenmiş ilaç tepsilerinin, standart öğle yemeği kutularının vb. işlenmesi için kullanılabilir. Boyutu nispeten büyüktür ve paketleme ile vakumlama verimliliği diğer makinelere göre birkaç kat fazladır.

Eğer vakum paketleme için büyük bir talebiniz varsa veya üretim hattınızı tam olarak üretmek istiyorsanız, detaylı bir teklif için lütfen benimle iletişime geçin.

Vakum paketleme makinesi nasıl çalışır?

Bir endüstriyel vakum paketleme makinesi, bir paketin içindeki havayı uzaklaştırıp sonra sıkıca mühürleyerek çalışır. Süreç genellikle aşağıdaki adımları içerir:

1. Ürün yerleştirme

Bu, gerçek işlemlerden önce önemli bir adımdır. Ürünlerinizin yüksekliği, uzunluğu ve genişliği dahil olmak üzere boyutundan emin olmalısınız.

Daha sonra bunları vakum odasına veya mühürleme alanına koyun. Torba ağzı, makinenin ısıtılmış mühürleme şeritlerini tamamen kaplamalı, hava sızdırmasına neden olabilecek herhangi bir kırışıklık veya kıvrılma olmamalıdır.

Not: Harici bir hazneli vakum gıda mühürleyici kullanılıyorsa, torba açılışının vakum nozulu üzerine oturması ve mühürünün ısıtmalı şeritlerle hizalanması gerekir.

2. Hava tahliye işlemi

Ürün yerleştirildikten sonra vakum pompası poşetten havayı uzaklaştırmak için etkinleştirilir. Çift hazneli vakumlu gıda paketleme makinesi kullanıyorsanız, bir tarafı yüklerken diğer taraf çalışıyor olabilir; bu da verimliliği önemli ölçüde artırır.

3. Diğer işlemler

Vakum mühürleyici paketleme makinesi, hassas gıdaların tazeliğini korumak ve kırılmalarını önlemek için koruyucu gazlar (azot veya karbondioksit gibi) enjekte eden bir cihazla donatılabilir.

Ayrıca üretim tarihi ve son kullanma tarihi gibi diğer bilgileri yazdırmak için bir yazıcı cihazı ile donatılabilir.

Vakum paketleme makinesi hakkında SSS

1. Makinenin malzemesi nedir?

304 paslanmaz çelik, çelik plaka kalınlığı 3mm, vakum odası kapağı 3mm, gövde 1mm

2. Makinenin güç modu nedir?

Elektrikli ısıtma ile yapılmıştır

3. Hava kompresörüne ihtiyacınız var mı?

Gerekli değil

Vakum paketleme makinesi ne kadar?

Farklı modellerin farklı fiyatları vardır. Ancak aşağıya bir mesaj bırakabilir ve detaylar için müşteri hizmetlerine danışabilirsiniz.

Taizy uzun yıllardır paketleme sektöründe faaliyet göstermektedir. Ürünlerimiz dünya çapında satılmakta olup, birçok şirketle iyi iş ilişkileri kurduk.

Bu makine hakkında başka sorularınız varsa, lütfen benimle rahatlıkla iletişime geçin.