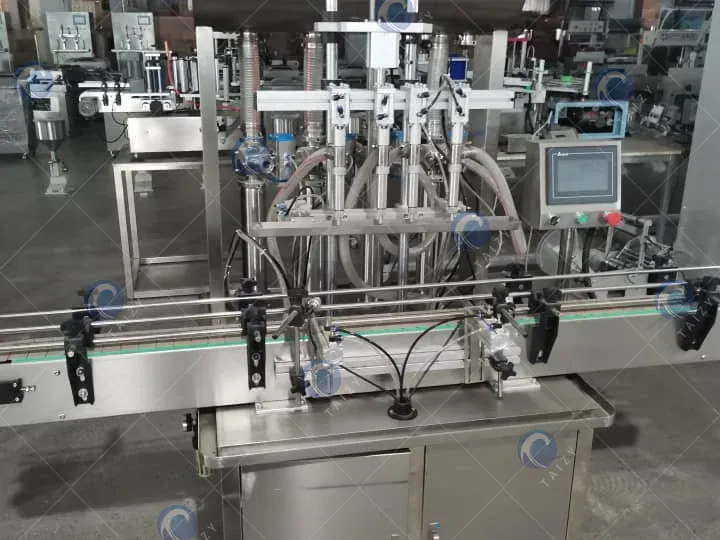

Mashine hii ya kujaza kioevu inaweza kujaza chupa 500-2000 za 500 ml kwa saa, ambayo ina ufanisi wa juu. Inatoa hesabu sahihi, na kosa la kujaza kuwa chini ya 1% kwa kiasi zaidi ya 100 ml. Wigo wake wa kujaza ni kutoka 500 hadi 2000ml, ambao unakidhi mahitaji mengi ya viwanda ya kujaza vinywaji.

Wakati huo huo, mashine ya kujaza chupa ya kioevu ya Taizy inatumiwa sana katika kujaza kioevu, kioevu wenye unyevunyevu mkubwa, paste, na mchuzi katika sekta mbalimbali, ikijumuisha chakula, dawa, kemikali, kemikali za kila siku, mafuta, dawa za wanyama, viuatilifu, na nyinginezo.

Kwanini wazalishaji wengi wa vyakula huchagua mashine yetu ya kujaza kioevu?

Wateja wengi wetu huweka mashine za kujaza kioevu na paste katika mistari ya uzalishaji wa chakula au aina nyingine za uzalishaji. Lakini kwanini walichagua aina hii ya vifaa? Hapa kuna sababu kadhaa:

- Mashine nzima imetengenezwa kwa nyenzo za SUS304, zinazofuatana na viwango vya GMP. Inaunda mazingira ya kisono kwa uzalishaji wa chakula na kuhakikisha ubora wa bidhaa.

- Kutumia motor ya servo iliyopandikizwa kuendesha kanta ya piston, mashine hii ya kujaza chupa ya kioevu inafanikisha upimaji wa kiasi, ujazo sahihi wa kujaza, na kazi ya kuhesabu.

- Ikiwa ungependa kubadilisha maalum au kurekebisha ujazo wa kujaza, unaweza kufanya hivyo moja kwa moja kwenye skrini ya kugusa, ambayo ni rahisi na inafaa. Pia inakuja na video za mafunzo na mwongozo wa mashine, ikifanya iwe rahisi kuanza kuitumia.

- Imezinduliwa na mfumo wa picha wa Panasonic wa Japan, inaweza kubaini kwa usahihi hali ya nafasi za chupa za kujaza, na itafanya kazi tu wakati chupa zinapotambuliwa.

Aina tofauti za mashine za kujaza kioevu na vigezo vyao vya kiufundi

Kuna aina mbili za mashine za kujaza: mashine za kujaza kioevu na mashine za kujaza paste. Mashine ya kujaza paste ina blender moja zaidi kuliko ile ya kioevu. Na unaweza kuchagua mashine maalum ya kujaza kwa nyenzo zako.

Hapa kuna baadhi ya vigezo vyao kwa uwezo tofauti.

| Aina | AT-SFGZ-L4 | AT-SFGZ-L6 | AT-SFGZ-L8 | AT-SFGZ-L12 | AT-SFGZ-L16 |

| Tuno za kujaza | 4 | 6 | 8 | 12 | 16 |

| Wigo wa upimaji | 500-2000 ml | 500-2000 ml | 500-2000 ml | 500-2000 ml | 500-2000 ml |

| Usahihi wa kujaza | ±1%(100 ml) | ±1%(100 ml) | ±1%(100 ml) | ±1%(100 ml) | ±1%(100 ml) |

| Uwezo wa uzalishaji (kulingana na 500 milliliters) | 500-1000 chupa/h | 800-1600 chupa/h | 1000-2000 chupa/h | 1500-3000 chupa/h | 2000-4000 chupa/h |

| Shinikizo la msaada wa hewa | 0.5-0.7 mpa | 0.5-0.7 mpa | 0.5-0.7 mpa | 0.5-0.7 mpa | 0.5-0.7 mpa |

| Matumizi ya hewa | 20 L/t | 30 L/t | 40 L/t | 60 L/t | 100 L/t |

| Jumla ya nguvu | 2.0 KW | 2.0 KW | 2.0 KW | 2.0 KW | 2.0 KW |

| Uzito | 300 kg | 400 kg | 500 kg | 700 kg | 900 kg |

| Vipimo vya jumla | 400*110*210 cm | 400*110*230 cm | 400*115*230 cm | 600*100*230 cm | 600*100*230 cm |

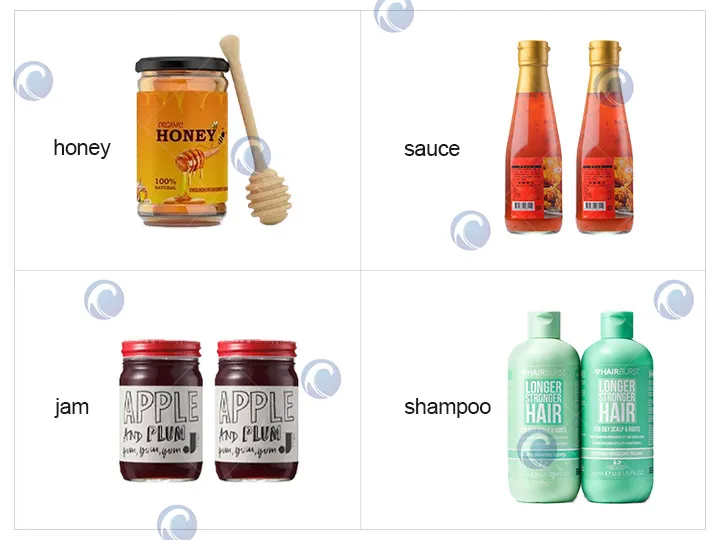

Wigo wa matumizi wa mashine hii ya kujaza chupa ya kioevu

Ikiwa ungependa kujua wigo wake wa matumizi, unahitaji kukidhi masharti mawili:

- Chombo kinaweza kuwa chupa, makopo, au ndoo.

- Nyenzo ni kioevu kinachoelea au paste.

Hivyo, baada ya kukidhi kanuni hizi mbili, unaweza kuchagua mashine inayofaa.

Maombi ya mashine ya kujaza chupa za kioevu:

- Sekta ya chakula: maji, juisi, mafuta, siki, bidhaa za maziwa, etc.

- Sekta ya dawa: kujaza dawa za kioevu, syrup, suluhisho za mdomo, etc.

- Sekta ya kemikali za kila siku: bottling liquid detergents, shampoos, conditioners, lotions, liquid soaps, disinfectants, etc.

Maombi ya mashine ya kujaza chupa za paste:

- Sekta ya chakula: siagi ya karanga, jam, asali, mchuzi wa nyanya, mchuzi wa pilipili, mchuzi wa sesame, etc.

- Sekta ya dawa: ointments, gels, creams, herbal extracts, etc.

- Sekta ya kemikali za kila siku: krimu za uso, lotions za mwili, conditioners za nywele, dawa za meno, gels za kusafisha mikono, etc.

Vipengele kwa undani vya mashine ya kujaza chupa ya kioevu

1. Upakiaji wa bidhaa kwenye conveyor: Upana wa kawaida ni 101mm, na ubadilishaji wa kipekee unakubalika.

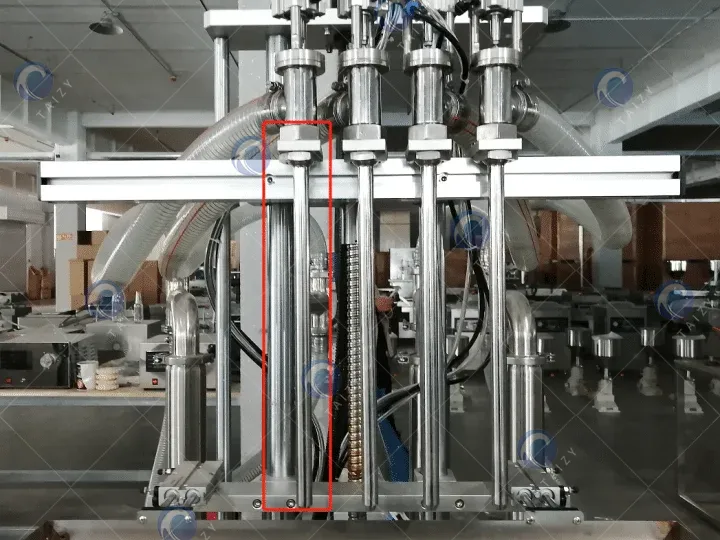

2. Tuno za kujaza: Urefu wa tuno unapatikana kwa miundo miwili. Ile ndefu itakuwa karibu zaidi na chini ya chupa kuliko ile fupi wakati wa kujaza. Inaweza kuzuia povu na ugumu wa kufunga kwa ufanisi.

3. Blender daima inafaa kwa kujaza chupa au makopo ya paste (Maji tu ya kujaza hayahitaji kifaa hiki). Inaweza kujiunga na:

- Kazi hii ya kupashwa joto ni kuzuia kuimarika.

- Shaft ya kuchanganya inatumika kuzuia kujaza kwa usawa kwa vinywaji vinavyo kuwa na chembe.

- Kitambuzi cha kiwango cha kioevu ili kuhisi moja kwa moja kiwango cha nyenzo zilizobaki kwenye tanki.

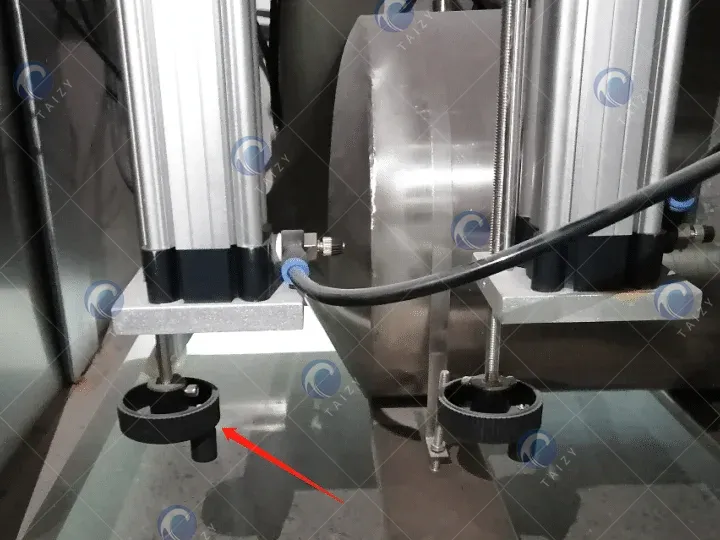

4. Valve ya kudhibiti mtiririko: Inadhibiti silinda kurekebisha ujazo wa kujaza kila chupa.

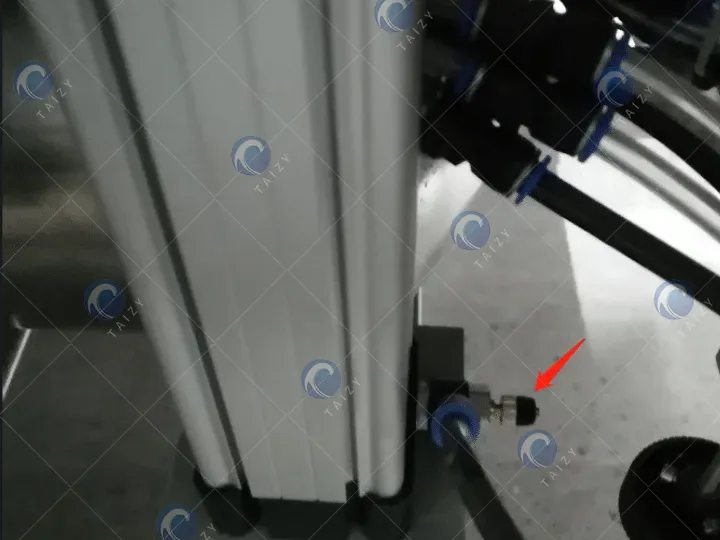

5. Valve ya kudhibiti shinikizo: Rekebisha mtiririko kudhibiti kasi ya kufunika.

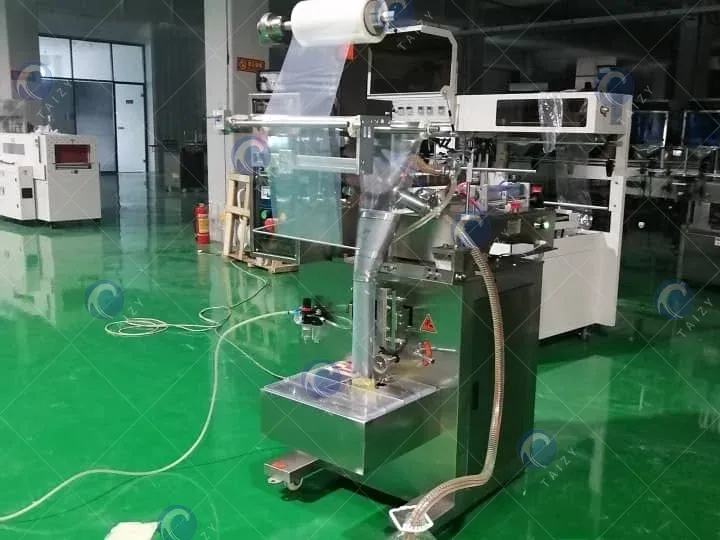

Mstari wa uzalishaji wa juisi ulioboreshwa wa kiotomatiki kabisa

Kwa mahitaji ya usindikaji wa bidhaa za ubora wa juu na kiotomatiki kabisa, pia tunatoa mstari wa uzalishaji wa kujaza.

Inajumuisha kichujio cha vifuniko chenye lifti, mashine ya kujaza chupa ya kioevu, mashine ya kufunika kiotomatiki, upau wa kusafirisha kiotomatiki, mashine ya kuweka lebo kiotomatiki, na mashine ya kuweka tarehe na nambari.

1. Kichujio cha vifuniko chenye lifti

Inatumiwa kama kifaa cha msaada kwa mstari wa kujaza, na kazi yake kuu ni kusafirisha na kuweka vifuniko kiotomatiki.

| Nyenzo ya umeme | AC 220 V/50 Hz |

| Mzunguko wa vifuniko unaofaa | 30–60 mm |

| Msukumo wa hewa wa kazi | 0.5–0.8 MPa |

| Uzito | 85 kg |

| Uwezo wa uzalishaji | 25–65 pcs/min |

| Ukubwa | 800 × 800 × 2100 mm |

2. Mashine ya kujaza kioevu kiotomatiki kabisa yenye vichwa 6

Njia ya kujaza inatumia kanuni ya piston yenye kujisukuma yenyewe na inaweza kutumika kwa upakiaji wa otomatiki wa juisi/vinywaji.

| Wigo wa kujaza | 100–500 ml |

| Kasi ya kujaza | 1300–1500 chupa/saa (kulingana na 500 ml/chupa) |

| Usahihi wa kujaza | ±1 g |

| Voltage iliyokadiriwa | 3-phase 380 V |

| Nguvu iliyokadiriwa | 3.2 kW |

| Msukumo wa hewa wa kazi | 0.6–0.8 MPa |

| Uzito | 800 kg |

| Uwezo wa hopper | 45–70 kg |

| Ukubwa | 1800 × 950 × 2150 mm |

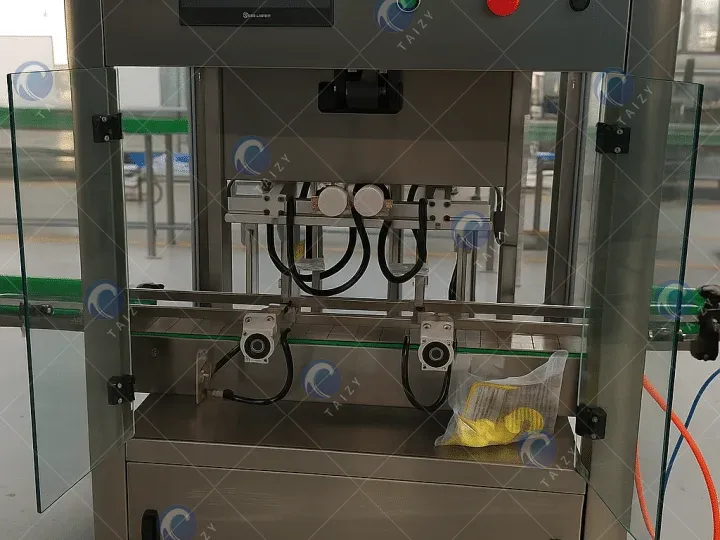

3. Mashine ya kufunika Tomatic

Inalingana na aina mbalimbali za chupa, hivyo hakuna haja ya kubadilisha sehemu wakati wa kubadilisha aina za chupa. Kipengele hiki cha kasi ya kufunika ya haraka na gharama ndogo kinakidhi mahitaji mengi ya uzalishaji wa kiotomatiki wa kampuni.

| Nyenzo ya umeme | AC 220 V/50 Hz |

| Urefu wa kufunga chupa | 80–150 mm |

| Mzunguko wa vifuniko unaofaa | 50–70 mm |

| Mtiririko unaofaa wa chupa | 50–80 mm |

| Msukumo wa hewa wa kazi | 0.5–0.8 MPa |

| Uzito | 350 kg |

| Uwezo wa uzalishaji | 30–45 chupa/min |

| Ukubwa | 800 × 900 × 1900 mm |

| Urefu wa conveyor | 800 ± 50 mm (inayoweza kurekebishwa kulingana na mstari wa uzalishaji wa mteja) |

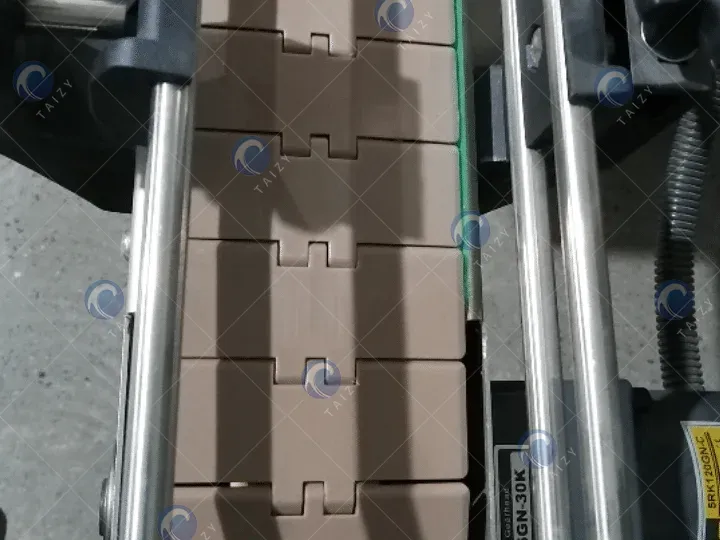

4. Upau wa kusafirisha kiotomatiki

Mnyororo wa conveyor umetengenezwa kwa kipande cha mnyororo wa POM. Inapunguza kwa ufanisi uzito wa kazi wa kushughulikia kwa mikono na kutimiza uotomatiki wa uzalishaji.

| Upana wa mkanda wa conveyor | 82.6 mm |

| Kasi ya conveyor | 2–6 m/s |

| Voltage iliyokadiriwa | 3-phase 380 V |

| Mfumo wa kudhibiti kasi | Mabadiliko ya mzunguko (udhibiti wa kasi unaobadilika) |

| Machine weight | 210 kg |

| Urefu kutoka ardhini | 850 mm ± 50 mm (inayoweza kubinafsishwa kwa ombi la mteja) |

| Nyenzo ya mkanda wa mnyororo | SUS304 chuma cha pua |

5. Mashine ya kuweka lebo kiotomatiki

Msimamo wa kuweka lebo na kifaa cha kusimama vinaweza kurekebishwa kulingana na ukubwa wa kitu kinachopakiwa lebo, ili bidhaa nyingi ziweze kuwekwa lebo kwa mashine ile ile.

| Kasi ya kuweka lebo | 25–65 chupa/min |

| Usahihi wa kuweka lebo | ±1.5 mm |

| Kasi ya upakiaji lebo | 3–50 m/min |

| Kasi ya conveyor | 5–30 m/min |

| Ukubwa | 2400 × 1400 × 1780 mm |

| Leboo zinazofaa | Leboo za rula zenye gundi za kujifunga moja kwa safu (wazi/si wazi); karatasi ya nyuma ya nusu-uwazi; (kipenyo cha ndani cha rula ya lebo: φ76.2 mm; kipenyo cha nje cha juu: φ340 mm; upana wa karatasi ya nyuma: 16–200 mm) |

| Uzito | 260 kg |

| Nyenzo ya umeme | AC 220V ±5%, 50/60 Hz |

| Ugavi wa hewa | 0.4–0.7 MPa |

| Joto la uendeshaji | 0–50 ℃ |

| Unyevu wa uendeshaji | 15–90% RH |

6. Mashine ya kuweka tarehe na nambari

Inaweza kuchapisha tarehe/wa wakati wa uzalishaji, tarehe ya kumalizika, nambari ya kundi, michoro, LOGO, na fomati nyingine.

| Urefu wa uchapaji | Unaoweza kurekebishwa 1–15 mm |

| Mistari ya uchapaji | 1–4 mistari, inayoweza kurekebishwa |

| Chaguzi za fonti | 5×8, 8×8, 12×8, 16×16, 24×24 (inaweza kubinafsishwa kwa ombi) |

| Kasi ya uchapaji | Hadi 128 m/min (mstari mmoja wa kasi kubwa) |

| Upanuzi wa upana wa herufi | Hadi upanuzi wa 9× |

| Ukubwa wa kichwa cha kuchapisha | 180 × 43 × 44 mm |

| Nyenzo ya umeme | 110–240 V, 50/60 Hz |

| Joto la uendeshaji | 5–45 ℃ (35–100 ℉) |

| Unyevu wa uendeshaji | ≤90% RH, isiyochanganyika |

| Ukubwa wa mashine | 555 × 300 × 320 mm |

Ikiwa ungependa kujifunza zaidi kuhusu mstari huu wa uzalishaji, nitumie ujumbe. Nitajibu swali lako haraka iwezekanavyo.

Mbali na aina hii ya mashine ya kujaza chupa za kioevu, pia tunatoa mashine za kujaza nusu-kiotomatiki na mashine za kujaza mzunguko, ambazo pia zinafaa kwa kujaza nyenzo za kioevu.

Ikiwa ungependa kupata maelezo zaidi kuhusu taarifa nyingine, nipigie simu au nitumie barua pepe, nitajibu haraka iwezekanavyo.