Um cliente nigeriano entrou em contato conosco, buscando uma linha de enchimento de manteiga de amendoim totalmente automática, especialmente projetada para recipientes de plástico com tampas, com capacidade aproximada de 500ml. O produto será fornecido ao mercado local, portanto, são necessários altos padrões de higiene e consistência na embalagem.

Requisitos do cliente nigeriano para toda a linha de enchimento de manteiga de amendoim

Durante nossa comunicação, o cliente expressou claramente várias exigências principais e esperava que pudéssemos fornecer uma solução abrangente:

- Devido à tendência da manteiga de amendoim de se separar e solidificar, o tanque de armazenamento do sistema de enchimento requer isolamento adicional e funções de agitação.

- O enchimento de manteiga de amendoim deve ser preciso e estável, com um erro controlado dentro de ±1%.

- Contentores de plástico e tampas requerem selagem automatizada, e a secção de embalagem necessita de uma função de impressão de data.

- Após a selagem, é necessário adicionar uma camada adicional de filme plástico na abertura.

Estes requisitos significam que máquinas de enchimento padrão não podem atender às demandas. Portanto, a nossa equipa profissional decidiu personalizar uma solução com base na situação específica do cliente.

Solução personalizada Taizy

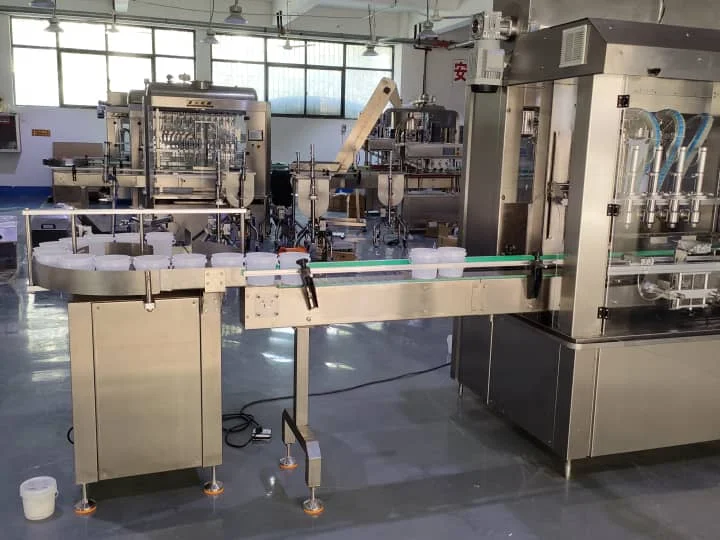

Com base nas necessidades reais de produção do cliente e na situação do mercado nigeriano, desenhámos uma linha de produção de enchimento e embalagem de manteiga de amendoim totalmente automática, integrando enchimento, tampagem, rotulagem e selagem num processo fluido.

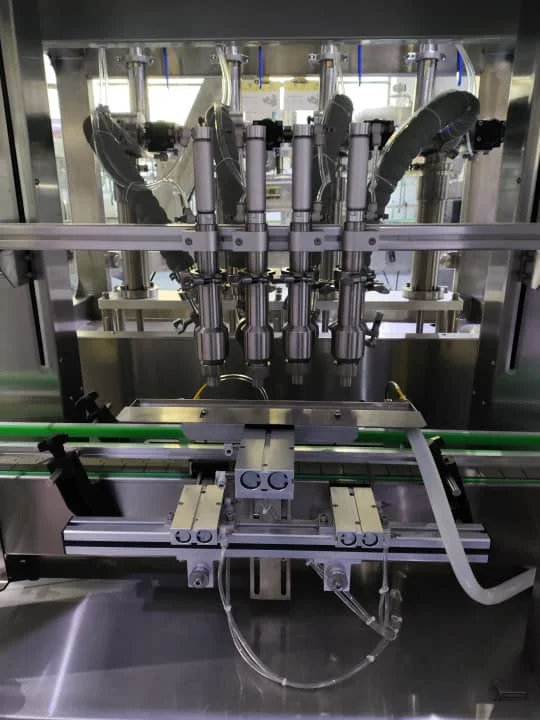

O núcleo desta linha de produção é uma máquina de enchimento de manteiga de amendoim de alta viscosidade, especificamente desenhada para embalar produtos espessos e pastosos. Possui alta precisão de enchimento e capacidade ajustável, equipada com bicos de enchimento anti-gotejo para evitar derrames e desperdício de material.

A linha de enchimento de manteiga de amendoim usa aço inoxidável de grau alimentício como material de contacto, garantindo qualidade enquanto controla razoavelmente os custos. Fornecer produtos de alta qualidade e custo-efetivos aos clientes tem sido sempre a busca da Taizy.

Além disso, a nossa solução também inclui classificação de garrafas, tampagem e selagem de plástico, atendendo perfeitamente a todos os requisitos do cliente.

Como pode obter soluções de embalagem personalizadas?

- Antes de iniciar o processo de personalização, é necessário fornecer o tipo de produto, temperatura de enchimento, se contém partículas e sua sensibilidade ao ar (produtos propensos à oxidação podem requerer purga de nitrogênio).

- As soluções de embalagem personalizadas devem focar no recipiente, incluindo o seu material, capacidade aproximada, forma do recipiente, diâmetro do gargalo da garrafa e tipo de tampa (rosca, pressão, selo interior). Isto facilita aos técnicos fazer avaliações e configurar a maquinaria adequada.

- Para garantir que a solução realmente atenda às suas necessidades operacionais, também a personalizaremos com base em fatores como espaço na fábrica, fornecimento de energia (tensão, fase), etc. Isto ajuda a determinar o planeamento do layout da linha de produção, a seleção do motor e do sistema de controlo, e a compatibilidade dos componentes elétricos.

A Taizy é uma fornecedora de fábrica com mais de uma década de experiência no design e fabricação profissional de linhas de produção e máquinas de embalagem personalizadas. Se tiver algum problema relacionado com embalagem, entre em contato conosco.

Algumas outras opções de enchimento: