As a kind of shrink packaging equipment, flow wrap packaging machines are engineered to produce such daily necessities as bread, chocolate, and soap in the food and light industries. It can package 25-230 bags per minute.

Standing out for the great reputation around the world, Taizy offers advanced professional flow wrapper machines with simple but effective operation, quick and adjustable settings, as well as great accuracy and precision.

Advantages of flow wrap packaging machine

High Precision and Non-stick Assurance

Thanks to our equipment’s high-precision positioning and tracking capabilities, sharp blades, and advanced photoelectric sensors, the laminating and cutting processes are kept clean and non-stick, ensuring packaging integrity and neatness.

Humanized Design and International Standard

Our bread packaging machine utilizes world-renowned electrical components and incorporates an intelligent PLC and touchscreen system. It also provides convenient parameter settings, rapid fault detection, and easy operation and upgrades, ensuring ease of operation and user-friendliness.

Motor Control and Complete Process

Packing speed and length of this flow wrap packaging machine are precisely controlled by servo motors, enabling infinitely variable speeds to meet diverse packaging needs.

Temperature Control and Tight Seal

Equipped with an independent Proportion Integration Differentiation (PID) technique, which adjusts the sealing temperature based on the melting points of raw materials to achieve the best sealing effect and ensure the packaging looks great.

Flow wrap packaging machine’s Parameters

There are two types of film feeding for cookie packaging machines:

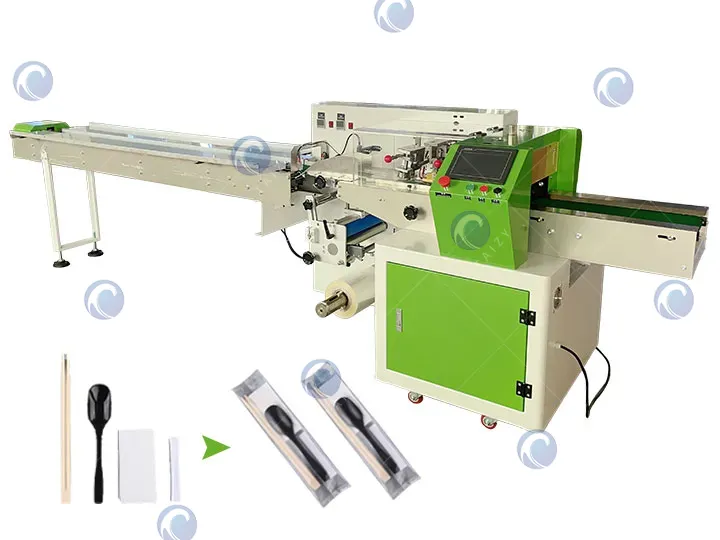

One is the upper feeding packaging machine, which is suitable for items with harder materials or surfaces (such as candy, biscuits, soap, cotton swabs). In contrast to that type, the lower feeding packaging machine is suitable for items with softer materials (for example, towels, clothes, masks).

Taizy flow wrap packaging machine has three models, and the detailed technical parameters are as follows:

| Type | TZ-350 | TZ-450 | TZ-600 |

| Film width | No more than 350 mm | No more than 450 mm | No more than 600 mm |

| Bag length | 65-190mm/120-280 mm | 100-600 mm | 130-540 mm |

| Bag width | 50-160 mm | 50-210 mm | 70-280 mm |

| Product height | No more than 60 mm | 100 mm | No more than 110 mm |

| Film roll diameter | No more than 320 mm | No more than 320 mm | No more than 320 mm |

| Packaging rate | 25-120 bags/min | 30-80 bags/min | 20-80 bags/min |

| Packaging materials | OPP,OPP/CPP,KOP/CPP,ALU-FILM | OPP,OPP/CPP,KOP/CPP,ALU-FILM | OPP,OPP/CPP,KOP/CPP,ALU-FILM |

| Power | 220 V, 50/60 Hz, 2.6 KW | 220 V, 50 Hz, 2.6 KW | 220 V, 50/60 Hz, 3.6 KW |

| Machine size | 4020*820*1450 mm | 4020*720*1450 mm | 4030*900*1650 mm |

Note: Film width=(width+height)×2+2cm

Besides, the machinery can be equipped with inflation (air or nitrogen) and coding devices for filling and coding. If you would like to inquire about the possibility of customizing other accessories, please feel free to send me a message.

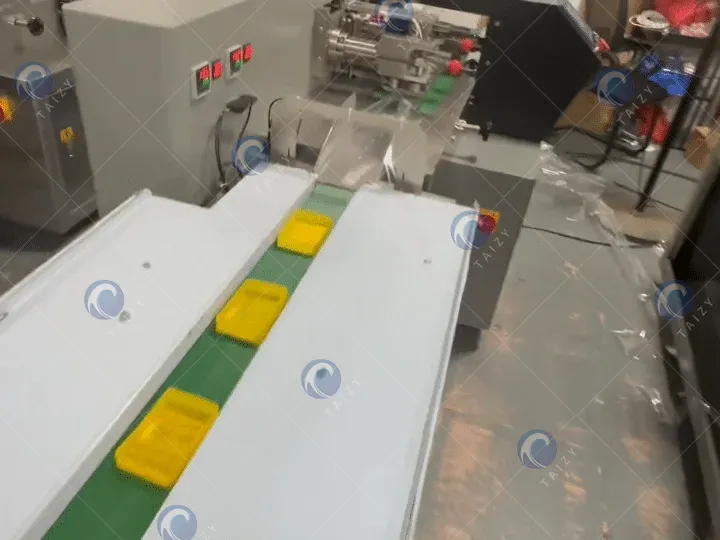

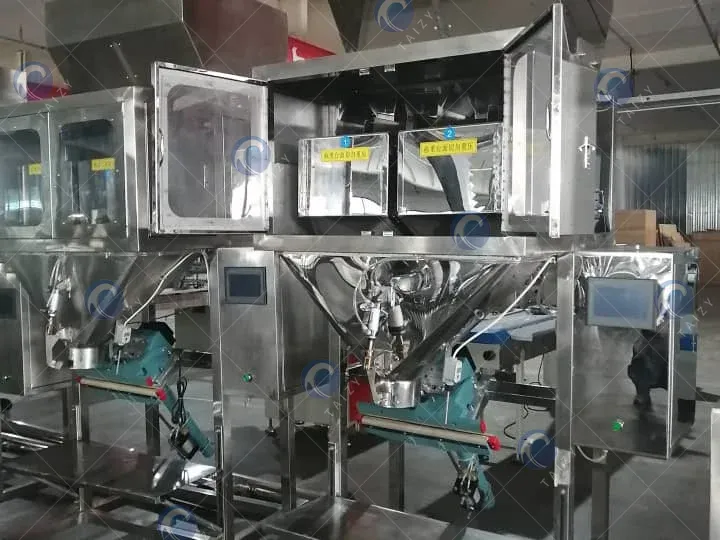

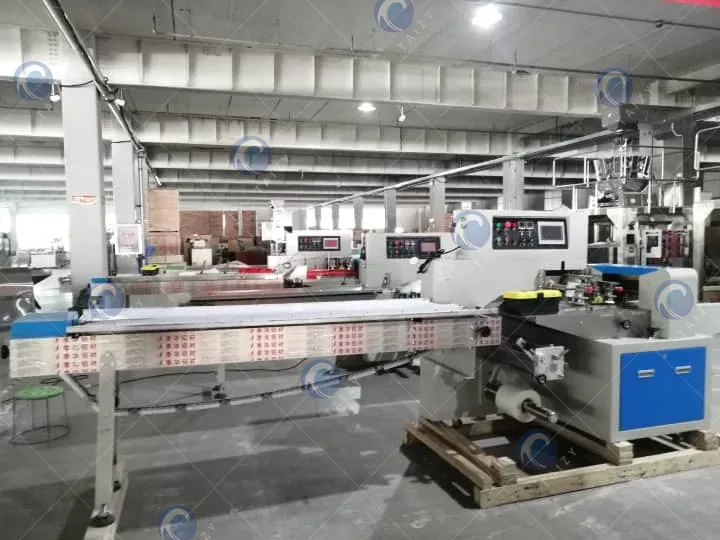

As the source manufacturer, we pay more attention to the quality of the machine. Below are some pictures of our factory. If you want to check the quality of the machine, please feel free to visit our factory. If you have any questions, please contact me

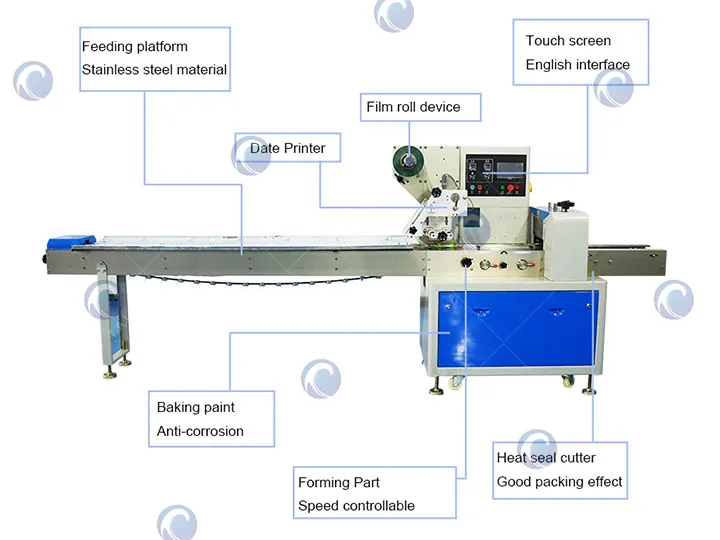

Pillow packing machine’s structure

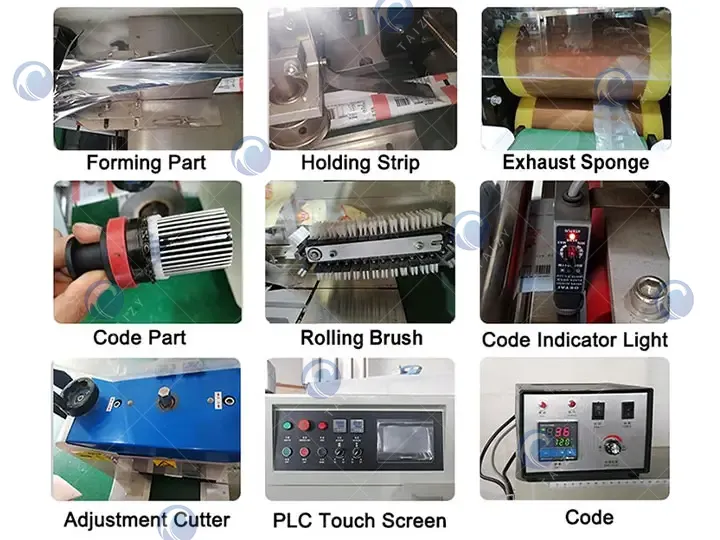

Our packing machine integrates a machine head, a machine body, a feeding platform, a date printer, a film roll device, a product pusher, a touch screen, an output conveyor, and an end sealing device.

Some parts can be customized according to your real needs:

- There are two types of conveyor belts to choose from: belt type and snap type. You can choose it for different materials. (If you don’t know how to choose, don’t hesitate to ask us!)

- This flow wrap packaging machine is classified into top film feeding and bottom film feeding types. According to the hardness of the object, you can decide the type.

- Sponge and brush accessories can be used to facilitate packaging and air evacuation.

In addition, if needed, we will equip you with a roller brush, whose primary function is to flatten and compact the surface of the packaging film, maintain its flatness, and continuously transport it forward through the conveyor belt throughout the entire process to form a complete assembly line.

Application of flow wrap packaging machine

Such an automatic packer can be applied to packing solid pieces of food, such as cakes, pies, caramel treats, chocolate, candy, bread, instant noodles, biscuits, and pills, as well as other regular daily necessities like towels, soap, masks, and clothes.

It can also be applied to toys and stationery, plastic products, industrial supplies, disposable products, hardware, industrial parts, and even automotive parts.

How the candy flow wrapping machine works

Packing part work progress:

- Folding the plastic bag together

- Heating bag

- Sealing the bag together

Cutting part work progress:

After the bags pass through the clamp, the rotating knife roll will automatically cut them off.

Brief flow wrap packaging machine’s working procedure

Conduct Safety Inspection → Turn on the Main Power Switch and Heater Switch → Set the Bag Length → Install the Packaging Film → Adjust Color Code → Adjust Material Location → Trial Run → Normal Production

Common error corrections of bread packaging machine

Film deviation

If the film moves away from the normal position, adjust the film wheel and raise the bag former to just push the block without touching the film. If in vain, the paper feed encoder or components may not work. That requires an immediate replacement of the corresponding parts. After selecting the suitable replacement, you need to change the width of the filmmaker to adjust the hand-wheel, thus making the width suitable.

Content cut by the cutter

If the things contained in films are cut by knives or cutters, you need to adjust the position of these materials, and then adjust the degree of compression of the pressing spring sheet on the product. After that, you also need to adjust the height of the horizontal seal to make sure the engagement surface of the cutter is in the middle position of the product level.

Failure to align the color mark

First, reset the length and clean up the dirt and black spots on the roller. Second, adjust the distance between the high photoelectric eye and the film or the sensitivity knob on the high photoelectric eye. Third, adjust the angle of the clamp block connecting to the spring on the brake hand, and set the compensation value to about 38.

Please refer to the product manual for detailed operation steps and acquaintance methods. For any further questions, please feel free to leave messages at any time. We will contact you as soon as possible.

Besides this flow wrap packaging machine, we still provide other types of equipment.

If you want to bag liquid, a paste packaging machine is a better choice. A liquid pouch filling machine will help pack water, milk, etc., products. If you have any confusion, just let me know. Click the contact, ask for the detailed price and information!