ਸਾਡੇ ਗਾਹਕ ਦਾ ਪਰਿਵਾਰਕ ਬੇਕਰੀ ਚਲਦਾ ਹੈ। ਵਿਆਪਕ ਕਿਸਮ ਬਹੁਤ ਨਹੀਂ ਹੈ, ਪਰ ਇਹ ਸ੍ਰੀ ਲੰਕਾ ਦੇ ਲੋਕਾਂ ਵਿਚ ਬਹੁਤ ਪ੍ਰਸਿੱਧ ਹੈ। ਆਨਲਾਈਨ ਖਰੀਦਦਾਰੀ ਦੇ ਵਿਕਾਸ ਨਾਲ, ਉਸ ਦੇ ਆਦੇਸ਼ ਬਹੁਤ ਵਧ ਗਏ ਹਨ। ਹੱਥੋਂ ਪੈਕੇਜਿੰਗ ਹੁਣ ਰੋਜ਼ਾਨਾ ਦੀਆਂ ਜ਼ਰੂਰਤਾਂ ਨੂੰ ਪੂਰਾ ਨਹੀਂ ਕਰ ਸਕਦੀ, ਇਸ ਲਈ ਉਹ ਇੱਕ ਪੂਰੀ ਤਰ੍ਹਾਂ ਆਟੋਮੈਟਿਕ ਫਲੋ ਰੈਪਰ ਮਸ਼ੀਨ ਦੀ ਖੋਜ ਕਰ ਰਹੀ ਹੈ। ਫਿਰ ਉਹ ਸਾਡੇ ਨਾਲ ਸੰਪਰਕ ਕਰਦੀ ਹੈ।

The efficiency crisis of the bakery workshop

ਪਹਿਲੀ ਸੰਚਾਰ ਦੌਰਾਨ, ਗਾਹਕ ਵੱਲੋਂ ਦਿੱਤੀ ਜਾਣਕਾਰੀ ਤੋਂ ਸਾਨੂੰ ਪਤਾ ਲੱਗਿਆ ਕਿ ਉਹ ਜਿਹਨਾਂ ਉਤਪਾਦਾਂ ਨੂੰ ਪੈਕ ਕਰਵਾਉਣਾ ਚਾਹੁੰਦੀ ਸੀ ਉਹ ਵੱਖ-ਵੱਖ ਆਕਾਰਾਂ ਦੇ ਬ੍ਰੈਡ ਅਤੇ ਬਿਸਕੁਟ ਸਨ। ਉਸ ਨੇ ਉਮੀਦ ਕੀਤੀ ਕਿ ਅਸੀਂ ਸਿਰਫ਼ ਇੱਕ ਮਸ਼ੀਨ ਦੇ ਸਕੀਏ ਜੋ ਉਸਦੇ ਸਾਰੇ ਆਕਾਰ ਦੇ ਉਤਪਾਦ ਪੈਕ ਕਰ ਸਕੇ।

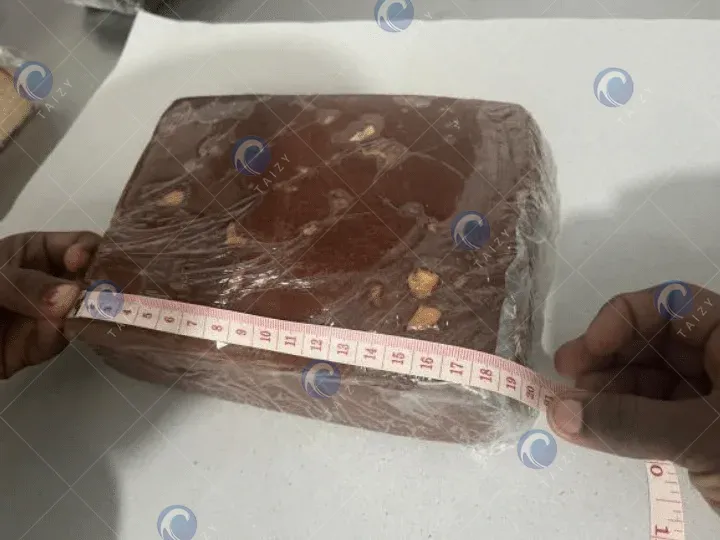

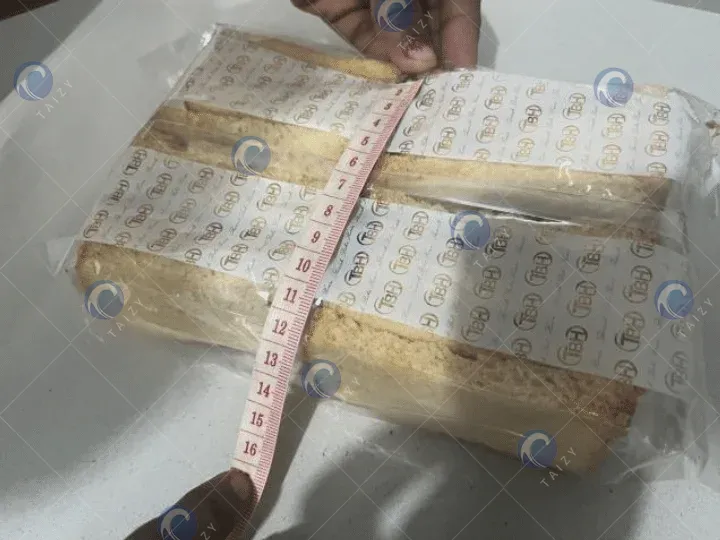

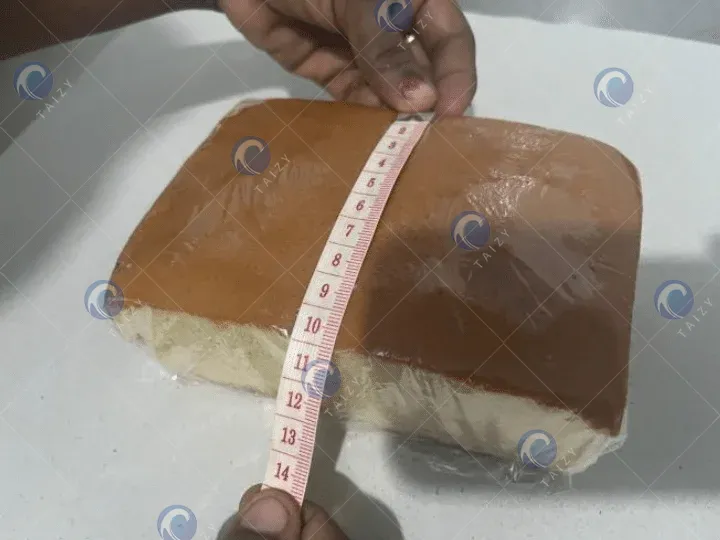

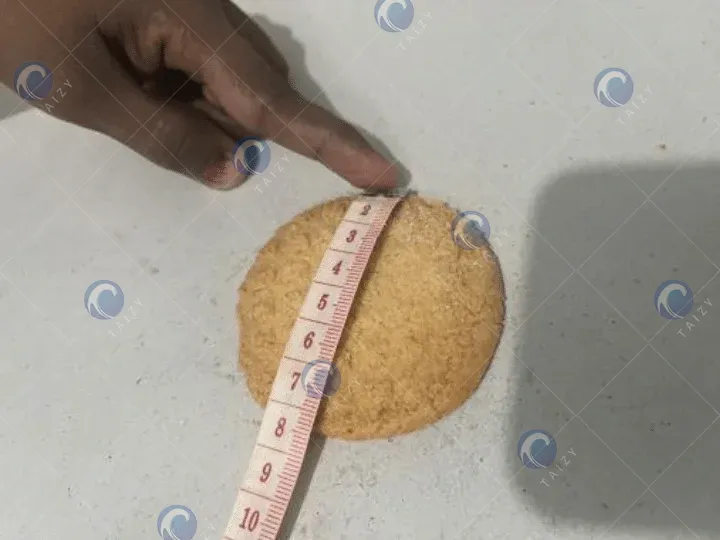

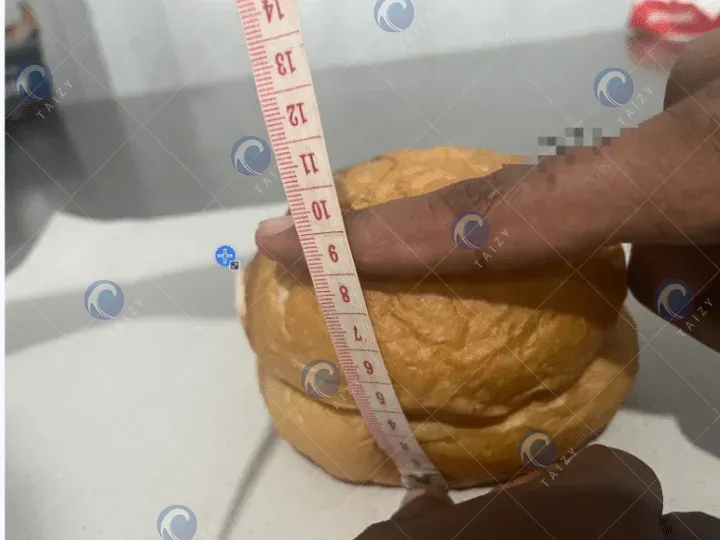

ਉਸ ਦੀ ਵਰਣਨਾ ਅਤੇ ਵਾਧੂ ਫੋਟੋਆਂ ਤੋਂ, ਅਸੀਂ ਉਸਦੇ ਉਤਪਾਦਾਂ ਦੇ ਆਕਾਰ ਜਾਣ ਲਏ:

| ਉਤਪਾਦ | Length | ਚੌੜਾਈ | ਉਚਾਈ | Diameter |

| Product 1 | 185 mm | 150 mm | 75 mm | \ |

| Product 2 | 185 mm | 125 mm | 55 mm | \ |

| Product 3 | 185 mm | 10 mm | 70 mm | \ |

| Product 4 | \ | \ | 55 mm | 90 mm |

| Product 5 | \ | \ | \ | 80 mm |

| Product 6 | \ | \ | 100 mm | 130 mm |

“ਮੈਂ ਇੱਕ ਵਾਰ ਆਪਣੇ ਹੱਥ ਨਾਲ ਉਹਨਾਂ ਨੂੰ ਪੈਕ ਕੀਤਾ ਸੀ। ਹਾਲਾਂਕਿ ਅਸੀਂ ਥੱਕ ਜਾਂਦੇ ਸੀ, ਫਿਰ ਵੀ ਆਦੇਸ਼ ਪੂਰੇ ਕਰ ਲੈਂਦੇ ਸੀ। ਪਰ ਸਮਾਂ ਬਦਲ ਗਿਆ ਹੈ, ਅਤੇ ਸਾਡੇ ਤਰੀਕੇ ਵਿੱਚ ਸੁਧਾਰ ਦੀ ਲੋੜ ਹੈ ਤਾਂ ਜੋ ਮੈਂ ਆਪਣੇ ਨਵੇਂ ਬ੍ਰੈਡ ਦੀ ਖੋਜ ਲਈ ਵਧੇਰੇ ਸਮਾਂ ਦੇ ਸਕਾਂ।“ ਉਹ ਆਪਣੀ ਕੀਮਤ ਰੇਂਜ ਵਿੱਚ ਵਧੀਆ ਗੁਣਵੱਤਾ ਵਾਲੀ ਮਸ਼ੀਨ ਚਾਹੁੰਦੀ ਹੈ।

What solutions do we provide for her anxieties?

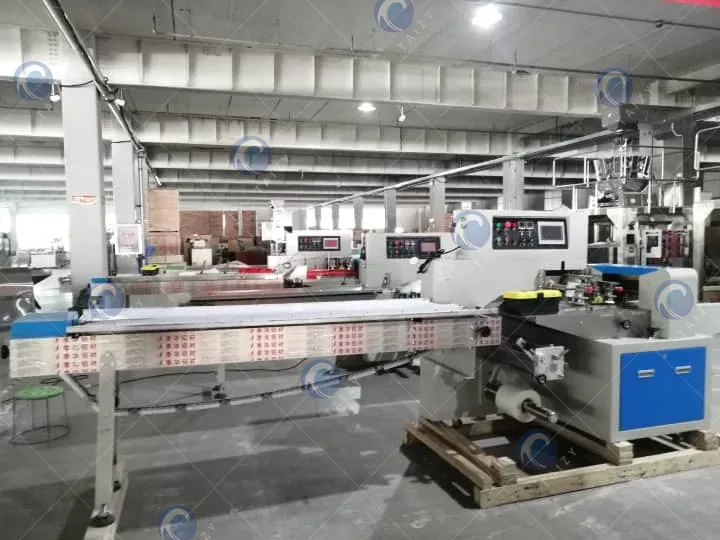

ਉਸਦੇ ਬ੍ਰੈਡ ਦੇ ਆਕਾਰ ਨੂੰ ਧਿਆਨ ਵਿੱਚ ਰੱਖਦੇ ਹੋਏ, ਅਸੀਂ ਬਾਟਮ ਪੇਪਰ ਵਾਲੇ ਫਲੋ ਰੈਪਰ ਮਸ਼ੀਨ ਦਾ ਸਭ ਤੋਂ ਵੱਡਾ ਮਾਡਲ ਸਿਫ਼ਾਰਸ਼ ਕੀਤਾ:

- TZ-600 ਮਾਡਲ 25-80 ਬੈਗ/ਮਿੰਟ ਤਿਆਰ ਕਰ ਸਕਦਾ ਹੈ। इसका अधिकतम ਫ਼ਿਲਮ ਚੌੜਾਈ 600mm ਤੱਕ ਪਹੁੰਚ ਸਕਦੀ ਹੈ ਅਤੇ ਬੈਗ ਚੌੜਾਈ ਦੀ ਰੇਂਜ 80 ਤੋਂ 280mm ਹੈ। ਇਹ 90mm ਤੋਂ ਘੱਟ ਉਚਾਈ ਵਾਲੇ ਉਤਪਾਦਾਂ ਨੂੰ ਵੀ ਪੈਕ ਕਰ ਸਕਦਾ ਹੈ, ਜੋ ਸਾਰੇ ਉਤਪਾਦਾਂ ਦੀ ਸੁਤੰਤਰਤਾ ਨਾਲ ਪੈਕੇਜਿੰਗ ਕਰਦਾ ਹੈ।

- ਉਤਪਾਦ ਦੀ ਵਿਸ਼ੇਸ਼ਤਾਵਾਂ ਨੂੰ ਦੇਖਦਿਆਂ, ਅਸੀਂ ਬਾਟਮ ਪੇਪਰ ਫੀਡ ਮਾਡਲ ਦੀ ਸਿਫ਼ਾਰਸ਼ ਕਰਦੇ ਹਾਂ। ਇਹ ਨਾ ਸਿਰਫ ਨਾਜੁਕ ਆਈਟਮਾਂ ਦੀ ਰੱਖਿਆ ਕਰਦਾ ਹੈ, ਬਲਕਿ ਪੈਕੇਜਿੰਗ ਨੂੰ ਵੀ ਸੁੰਦਰ ਅਤੇ ਸਮਤਲ ਬਣਾਉਂਦਾ ਹੈ। ਇੱਕੋ ਸਮੇਂ 'ਤੇ, ਅਸੀਂ ਬੈਕ ਸੀਲ ਵੀ ਪ੍ਰਦਾਨ ਕਰਦੇ ਹਾਂ, ਜਿਸ ਨਾਲ ਬੈਗ ਦੇ ਦੋਹਾਂ ਪਾਸਿਆਂ 'ਤੇ ਦਬਾਅ ਮਜ਼ਬੂਤ ਹੁੰਦਾ ਹੈ ਅਤੇ ਪੈਕੇਜਿੰਗ ਨੁਕਸਾਨ ਹੋਣ ਦੀ ਸੰਭਾਵਨਾ ਘੱਟ ਹੋ ਜਾਂਦੀ ਹੈ।

- ਇੱਕੋ ਸਮੇਂ, ਗਾਹਕ ਦੀਆਂ ਲੋੜਾਂ ਦੇ ਅਨੁਸਾਰ, ਅਸੀਂ ਸਮਾਂ ਪ੍ਰਿੰਟਰ ਫੰਕਸ਼ਨ ਅਤੇ ਨਾਈਟ੍ਰੋਜਨ ਭਰਨ ਸਿਸਟਮ ਵੀ ਕਸਟਮਾਈਜ਼ ਕੀਤੇ।

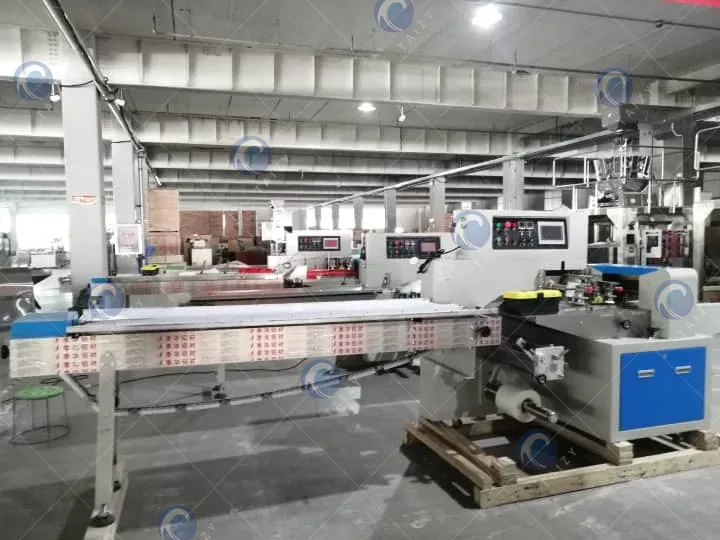

ਕਿਉਂਕਿ ਫੈਕਟਰੀ ਵਿੱਚ ਸਟਾਕ ਨਹੀਂ ਸੀ ਅਤੇ ਬਹੁਤ ਸਾਰੀਆਂ ਚੀਜ਼ਾਂ ਨੂੰ ਕਸਟਮाइज ਕਰਨਾ ਲੋੜੀਂਦਾ ਸੀ, ਅਸੀਂ ਆਰਡਰ ਦੀ ਪੁਸ਼ਟੀ ਤੋਂ 20 ਦਿਨਾਂ ਵਿੱਚ ਮਸ਼ੀਨ ਦੀ ਉਤਪਾਦਨ ਤੇਜ਼ ਕੀਤੀ। ਆਖ਼ਿਰਕਾਰ, ਫਲੋ ਰੈਪਰ ਮਸ਼ੀਨ ਸਾਡੇ ਫੈਕਟਰੀ ਵਿੱਚ ਟੈਸਟ ਕੀਤੀ ਗਈ ਅਤੇ ਸਮੇਂ ਤੇ ਸਫਲਤਾ ਨਾਲ ਸ੍ਰੀ ਲੰਕਾ ਨੂੰ ਭੇਜ ਦਿੱਤੀ ਗਈ।

Project results of Taizy flow wrapper machine

ਕੁਝ ਮਹੀਨਿਆਂ ਬਾਅਦ, ਉਸ ਨੇ ਸਾਨੂੰ ਸ਼ਾਨਦਾਰ ਫੀਡਬੈਕ ਦਿੱਤੀ: “ਮੇਰਾ ਕੰਮ ਹੁਣ ਕਾਫ਼ੀ ਆਸਾਨ ਹੋ ਗਿਆ ਹੈ, ਅਤੇ ਅਸੀਂ ਆਪਣੀ ਆਨਲਾਈਨ ਦੁਕਾਨ ਵੀ ਵਧਾਈ ਹੈ! ਮਸ਼ੀਨ ਖਰੀਦਣਾ ਇਕ ਨਿਵੇਸ਼ ਵਰਗਾ ਸੀ, ਪਰ ਇਹ ਸਪਸ਼ਟ ਹੈ ਕਿ ਮੈਂ ਸਹੀ ਸਪਲਾਇਰ ਅਤੇ ਸਹੀ ਉਤਪਾਦ ਚੁਣਿਆ, ਜਿਸ ਨੇ ਮੈਨੂੰ ਵਧੇਰੇ ਲਾਭ ਦਿੱਤੇ ਹਨ।”

ਇਸ ਵਪਾਰ ਤੋਂ ਬਾਅਦ, ਅਸੀਂ ਫ਼ਿਰ ਵੀ ਸੰਪਰਕ ਵਿੱਚ ਰਹਿੰਦੇ ਹਾਂ। ਕਈ ਵਾਰ ਉਹ ਮਸ਼ੀਨ ਦੀ ਚਾਲੂ ਕਰਨ ਦੀ ਵਿਧੀ ਨਹੀਂ ਸਮਝਦੀ, ਕਈ ਵਾਰ ਉਸਨੂੰ ਘਿਸਣ ਵਾਲੇ ਪਹਿਣਤ ਯਾਂ الجزء ਬਦਲਣ ਦੀ ਲੋੜ ਹੁੰਦੀ ਹੈ। ਇਹ Taizy ਵੱਲੋਂ ਦਿੱਤੀਆਂ ਆਫਟਰ-ਸੇਲਜ਼ ਸੇਵਾਵਾਂ ਹਨ। ਜੇ ਸਾਡੇ ਗਾਹਕਾਂ ਕੋਲ ਕੋਈ ਪ੍ਰਸ਼ਨ ਹੁੰਦੇ ਹਨ, ਅਸੀਂ ਧੀਰਜ ਨਾਲ ਉਨ੍ਹਾਂ ਦਾ ਜਵਾਬ ਦਿੰਦੇ ਹਾਂ।

ਜੇ ਤੁਸੀਂ ਵੀ ਪਰਫੈਕਟ ਪੈਕੇਜਿੰਗ ਹੱਲ ਦੀ ਖੋਜ ਕਰ ਰਹੇ ਹੋ, ਤਾਂ ਤੁਸੀਂ ਸਾਨੂੰ ਆਪਣਾ ਕਾਰੋਬਾਰੀ ਸਾਥੀ ਬਣਨ ਦਾ ਮੌਕਾ ਦੇ ਸਕਦੇ ਹੋ। Taizy ਦਾ ਉਦੇਸ਼ ਖਾਦ ਪੈਕੇਜਿੰਗ ਉਦਯੋਗ ਦੇ ਵਿਕਾਸ ਵਿੱਚ ਸਹਾਇਤਾ ਕਰਨਾ ਹੈ। ਜੇ ਤੁਹਾਡੇ ਕੋਲ ਕੋਈ ਲੋੜ ਹੈ, ਤਾਂ ਕਿਰਪਾ ਕਰਕੇ ਸਾਡੇ ਨਾਲ ਸੰਪਰਕ ਕਰੋ।

Click here for more details on the same product: flow wrap packaging machine for candy bread bagging.