Taizy machine d’emballage de sachets de thé est une solution entièrement automatique conçue pour l’emballage efficace de sachets de thé. Elle offre une production élevée de 20–60 sachets par minute et ne peut emballer que 1–40 g de thé, ce qui convient à des tailles de sachets allant de 50–80 mm de longueur et 45–80 mm de largeur.

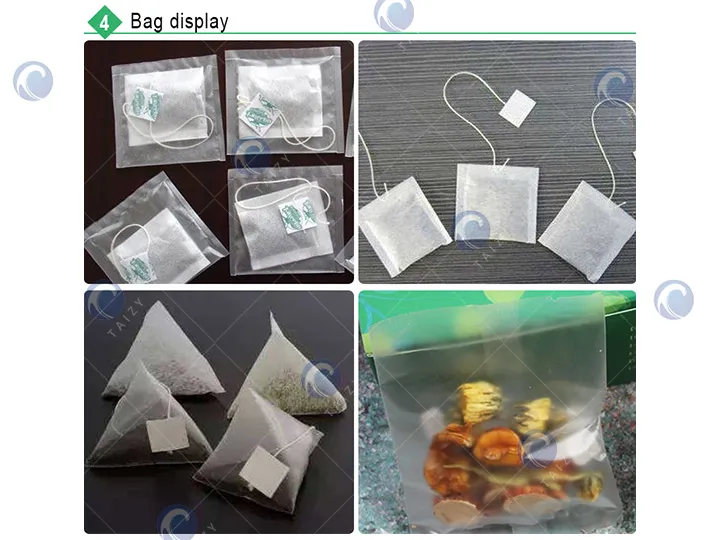

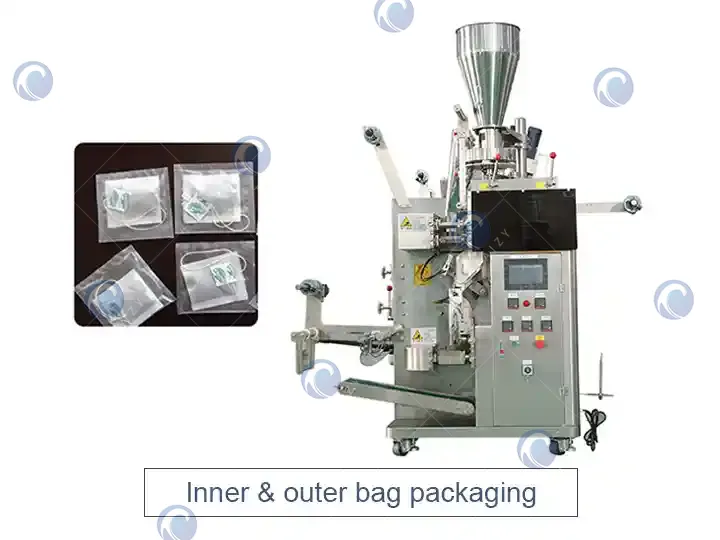

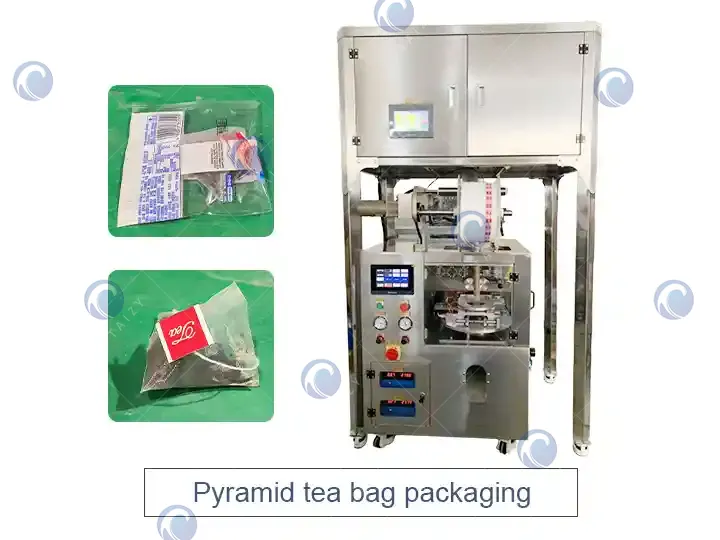

Nous concevons différents types de machines offrant diverses options d’emballage : emballage intérieur et extérieur intégré, emballage intérieur avec labels, étiquettes triangulaires en nylon, etc. Cette machine d’emballage de thé propose un scellement sur trois côtés et certains modèles offrent également une option de scellement sur quatre côtés avec des découpes esthétiques et un déchirement facile.

Caractéristiques de la machine d'emballage de thé chez Taizy

- Le papier d'emballage extérieur est contrôlé par un moteur pas à pas, assurant une longueur de sac stable et un positionnement précis de la coupe.

- Un contrôleur de température PID assure une température uniforme une précision accrue tout au long du processus.

- La machine entière utilise un contrôle PLC, une interface homme-machine, et une opération en un clic pour faciliter l'utilisation.

- Plusieurs pièces en contact avec le matériau sont en acier inoxydable 304, garantissant hygiène du produit et conformité aux certifications internationales.

- La machine d'emballage de sachets de thé Taizy peut être équipée de services personnalisés qui permettent découpe plate, impression de la date, et fonction de déchirure faciles.

- De nombreux styles peuvent être choisis: emballage intérieur et extérieur intégrés avec étiquettes, emballage intérieur avec étiquettes, étiquettes en nylon triangulaires, etc.

Domaine d'application de la machine d'emballage de thé

Cette machine d’emballage de sachets de thé est principalement conçue pour des produits à usage unique, granulaires fins ou en poudre. Elle est idéale pour emballer des éléments tels que la poussière de thé, les mélanges d’herbes, les dessiccants et des matériaux similaires. Parfaite pour résoudre les problèmes d’emballage des fabricants de thé.

The machine supports a wide range of packaging materials, including tea filter paper, composite films, and non-woven fabrics, which can be formed as three-sided sealing and four-sided sealing.

Structure de la machine d'emballage pour tisanes

This illustration shows the TZ-169 tea bag packing machine with an outer envelope. The machine features a touch screen, particle turntable, hopper, scroll, packaging shaper, photo sensor, and conveyor.

Différents modèles peuvent produire différents styles d’emballage pour répondre à divers besoins. Par exemple, si vous avez besoin de sachets de thé avec étiquettes, choisissez une machine d’emballage d’enveloppes de sachets de thé équipée d’un dérouleur pour planches d’étiquettes et ficelle. Vous ne savez pas quel modèle vous convient ? N’hésitez pas à nous contacter — nous vous aiderons à trouver la solution parfaite !

Les différents modèles et paramètres de la machine d’emballage de thé

Type 1 : sachet intérieur de thé avec étiquette

| Type | Sachet intérieur de thé avec étiquette |

| La forme de scellage | Scellement sur trois bords |

| Plage de pesée | 1-5g/sachet |

| La taille du sachet | Longueur 50-80mm; largeur 45-80mm |

| La taille de l'étiquette | (L*W) 20*28mm/ 20*25mm / 20*20mm |

| Capacité de production | 30-60sachets/min |

| La puissance d'entrée | 220v 50hz 1.6kw |

| Le poids | 380kg |

| Dimensions d'installation | 1250*750*1750mm |

Type 2 : sachet extérieur et intérieur de thé avec étiquette

| Type | Outer&inner tea bag with tag |

| La forme de scellage | Scellement sur trois bords |

| Plage de pesée | 3-10g/sachet |

| Taille du sachet intérieur | Longueur 50-70mm; largeur 45-80mm |

| Taille du sachet extérieur | Longueur 80-120mm; largeur 75-95mm |

| L'étiquette | Peut être personnalisée |

| Capacité de production | 30-40sachets/min |

| La puissance d'entrée | 220v 60hz 3.7kw |

| Le poids | 500kg |

| Dimensions d'installation | 1750*700*1950mm |

Type 3 : sachet de thé intérieur sans étiquette

| Type | Sachet de thé intérieur sans étiquette |

| La forme de scellage | Scellement tridimensionnel |

| Plage de pesée | 3-10g/sachet |

| Taille du sachet | Longueur 50-80mm; largeur 45-80mm |

| Capacité de production | 30-60sachets/min |

| La puissance d'entrée | 220v 50hz 1.6kw |

| Le poids | 220v 50hz 1.5kw |

| Dimensions d'installation | 350kg |

Type 4 : sachet pyramidal en nylon avec étiquette

| Type | Sachet de thé en nylon avec étiquette |

| La forme de scellage | Scellement tridimensionnel |

| Plage de pesée | 1-7g/sachet |

| Taille du sachet | Longueur 60-80mm; largeur 40-80mm |

| Capacité de production | 30-50sachets/min |

| La puissance d'entrée | 220v 50hz 3kw |

| Le poids | 450kg |

| Dimensions d'installation | 1310*1470*2110mm |

Autres types

| Type | Machine d'emballage intérieur et extérieur pour sachets de café filtre |

| Plage de pesée | Drip coffee bag inner & outer packing machine |

| Taille du sachet intérieur | 5–10g/sachet |

| Taille du sachet extérieur | Longueur 70–74mm; largeur 90mm |

| Capacité de production | Longueur 120mm; largeur 100mm |

| La puissance d'entrée | 20–35sachets/min |

| Le poids | 220v 50hz 3.7kw |

| Dimensions d'installation | 660kg |

| Type | Automatic Granular Packing Machine |

| Plage de pesée | Machine d'emballage pour granulés |

| Taille du sachet | 10–40g/sachet |

| Capacité de production | Longueur 40–110mm; largeur 30–80mm |

| La puissance d'entrée | 30–100sachets/min |

| Le poids | 220v 50hz 1.5kw |

| Dimensions d'installation | 350kg |

Vous pouvez comparer leurs styles d’emballage et leurs capacités pour trouver votre machine d’emballage de thé idéale. Si vous avez des questions, faites-le moi savoir. Envoyez-moi des messages pour obtenir plus de détails !

Pannes courantes de la machine et maintenance

- If you notice that the vacuum level is low, it is often caused by a vacuum pump becoming dirty and clogged, or a pump that has become worn over time. To resolve this, you can start by cleaning the vacuum pump thoroughly. If the problem persists, replace the vacuum pump to restore proper performance.

- Unusual noise during operation usually indicates that the exhaust filter is clogged or that the solenoid valve may be leaking. Regularly clean or replace the exhaust filter, and inspect the solenoid valve for leaks. Replace the valve if necessary to ensure stable operation.

- If the heating system fails, the most common reasons are a damaged heater, insufficient heating oil, or a faulty transformer. In such cases, replace the heater, refill or change the heating oil, and check the heating transformer. Replace the transformer if it is no longer functioning correctly.

We will provide detailed manuals and operation videos as our after-sales service. If you want to know more information, consult me without hesitation!

With the improvement of living standards, people pay more and more attention to health preservation. Tea, as a traditional health product, is deeply loved by people. In addition, exquisite tea packaging can attract consumers’ attention and influence their psychology. Therefore, the development market of tea packaging machines will be very broad. If you want to upgrade your brand with the help of packaging, Taizy will be a good partner.