The vacuum chamber sealer is widely used in the food industry, catering, pharmaceuticals, and even electronics. Its working principle is extracting air from the sealed chamber, which helps extend the shelf life of products, preserve freshness, and protect them from moisture, bacteria, and oxidation.

The following explains what a vacuum sealer is? How does it work? What are its applications? How to choose the right one for your needs? Whether you’re a restaurant owner, food processor, or small business owner, understanding how a vacuum sealer works will help you improve efficiency and product quality.

Introduction of the vacuum chamber sealer

Unlike external vacuum sealers, which only draw air from the bag, a vacuum chamber sealer removes air from the entire chamber. This process ensures a stronger and more consistent vacuum effect, making it ideal for both commercial and industrial applications.

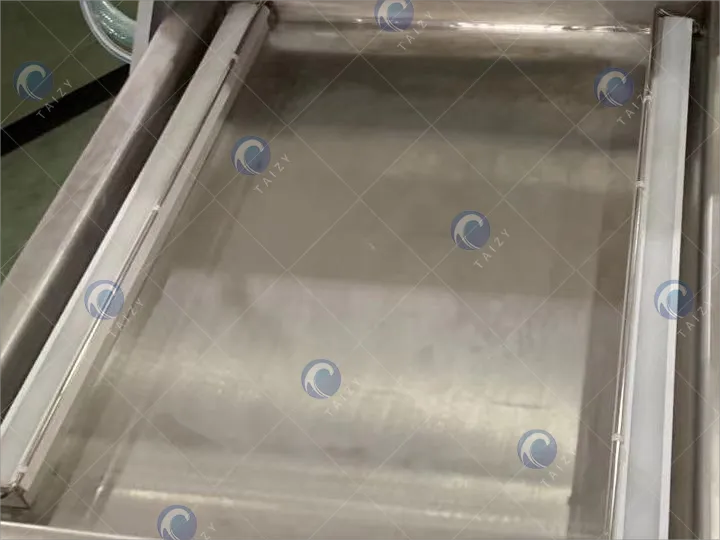

The key components of the vacuum chamber sealing machine mainly include: vacuum chamber, vacuum pump, sealing strip, and control panel.

- The vacuum chamber provides an enclosed space where bags are placed for sealing. It can make the vacuuming process more effective.

- The vacuum pump is the most important part of the whole vacuum chamber sealer. It removes air from the chamber and ensures low oxygen levels in the complete space.

- These sealing strips will melt and seal the edges of the bag, making it airtight.

- Normally, it will be equipped with control panels that allow operators to adjust vacuum time, sealing time, and temperature.

How does a chamer vacuum sealer work?

- The first step is to place the food or product into a specially designed vacuum bag. Check the bag for damage to prevent spillage.

- Secondly, place the bag into the vacuum chamber, with its open end neatly resting on the sealing strip.

- After closing the cover, the machine will extract air from the entire vacuum chamber.

- After the air is extracted, heated strips will melt the edges of the bag to create a secure seal.

- Finally, air flows back into the vacuum chamber, equalizing the pressure and pressing the sealed bag tightly around the product.

FAQs about vacuum chamber sealers

Chamber vacuum sealer vs non-chamber

Chamber sealers extract the air from the entire chamber, so they can handle liquid or juicy foods. However, external sealers only extract the air from the inside of the bag and are not suitable for liquid or high-water content foods.

Can a vacuum chamber sealer seal liquids?

Yes. Because after evacuating, there is no problem of liquid being “sucked into the sealing strip”, the vacuum packaging sealer is more suitable for sealing foods containing water, juice, or sauce.

Is it suitable for home use or only for industrial/commercial use?

Some tabletop, small chamber vacuum machines are designed for use in home kitchens or small studios. But most cavity sealing machines are more commercial because they are highly efficient and have a larger size.

Conclusion of vacuum chamber sealer

A vacuum chamber sealer is more than just a packaging tool, but an essential machine that ensures longer shelf life, better food safety, and professional packaging quality.

By understanding how it works, its advantages, and its wide range of applications. You can choose the right model for your businesses and individuals to improve efficiency and product value.

If you want to know more details about our vacuum sealer chamber machine, click this link to know them: Vacuum packaging machine for food sealing and storage.

For more information and a free quota, please contact us to gain them!