Taizy’s series of sauce filling machines is especially suitable for flowable paste materials such as ketchup, salad dressing, peanut butter, etc. The machine is made of stainless steel, meeting international food safety requirements, which is suitable for food processing factories of all sizes.

For small-scale production, we have launched a semi-automatic filling machine with an output of 8-25 bottles/min, which can fill 100-1000ml of product. The fully automatic filling machine can be put into the production line, its output is between 500-3000 bottles/h with a filling range of 10-5000ml.

Our sauce filling machines own international certificates such as CE and PVOC. Taizy has helped small factories invest in or acquire large production lines in countries such as Nigeria, the Philippines, Türkiye, and Chile. If you are looking for a reliable packaging solution, don’t hesitate to contact us!

Highlights of the sauce bottle filler

- Taizy sauce filling machines are made of 304 stainless steel. If you have custom requirements, we can also produce 316 stainless steel to meet your high demands.

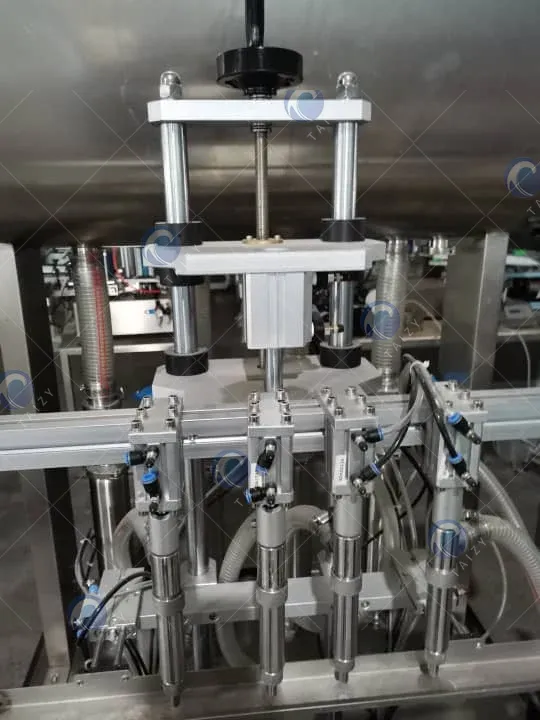

- Our machine is equipped with a regulating valve that can automatically control the filling volume by adjusting the stroke of the cylinder.

- The filling head length can be customized to suit different product containers’ requirements. It has a precise filling volume, with no dripping or leakage after filling, keeping the working surface clean and hygienic.

Two types of sauce-filling sealing machines

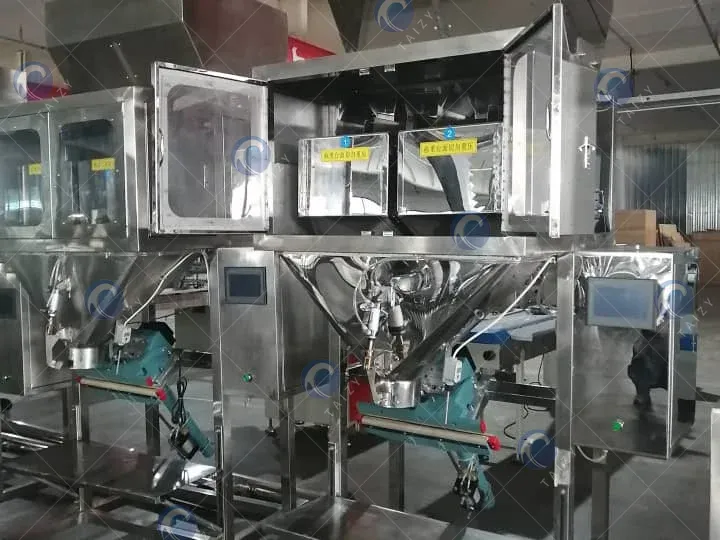

Type 1: Automatic sauce filling machine

Working principle of auto sauce bottle filler

With a fully automatic conveyor belt and induction device, this jar-filling machine has these customized functions, such as automatic capping/labeling to complete the filling and packaging process.

It is mainly controlled by a motor and has a piston pump to fill the sauce quantitatively. Only one employee can control the entire machine.

Parameters of the automatic sauce filling machine

| Type | AT-SFGZ-L4 | AT-SFGZ-L6 | AT-SFGZ-L8 | AT-SFGZ-L12 | AT-SFGZ-L16 |

| Filling nozzle | 4 | 6 | 8 | 12 | 16 |

| Measuring range | 500-2000 ml | 500-2000 ml | 500-2000 ml | 500-2000 ml | 500-2000 ml |

| Filling precision | ±1%(100 ml) | ±1%(100 ml) | ±1%(100 ml) | ±1%(100 ml) | ±1%(100 ml) |

| Production capacity (based on 500 milliliters) | 500-1000 bottles/h | 800-1600 bottles/h | 1000-2000 bottles/h | 1500-3000 bottles/h | 2000-4000 bottles/h |

| Air supply pressure | 0.5-0.7 Mpa | 0.5-0.7 Mpa | 0.5-0.7 Mpa | 0.5-0.7 Mpa | 0.5-0.7 Mpa |

| Air consumption | 20 L/t | 30 L/t | 40 L/t | 60 L/t | 100 L/t |

| Total power | 2.0 KW | 2.0 KW | 2.0 KW | 2.0 KW | 2.0 KW |

| Weight | 300 kg | 400 kg | 500 kg | 700 kg | 900 kg |

| Overall dimensions | 400*110*210 cm | 400*110*230 cm | 400*115*230 cm | 600*100*230 cm | 600*100*230 cm |

Successful case of the peanut butter filling machine

A customer from Tanzania processes and sells peanut butter, sesame paste, and other nut products. To expand production, they purchased a complete peanut butter production line from Taizy.

After observing the stable operation of the line, they decided to expand their factory’s capacity and purchase an additional fully automated sauce-filling line to improve packaging efficiency and reduce labor costs.

“We first bought the peanut butter processing line from Taizy, and it worked perfectly. That’s why we chose them again for the filling line. Now the entire production—from roasting to bottling—is fully automated. Production efficiency has doubled!”

Type 2: Manual paste filling machine

Working principle of semi-auto paste filler

The piston injection is activated by the foot switch or button, which requires people to place the bottles or cans. The whole control is simple and suitable for small and medium-sized workshops.

Parameters of the manual paste filling machine

| Model | TZ-G1 | TZ-G2 |

| Power supply | 220/110 V 50/60 Hz | 220/110 V 50/60 Hz |

| Filling range | 100-1000 ml | 100-1000 ml |

| Air pressure | 0.4-0.6 Mpa | 0.4-0.6 Mpa |

| Packing speed | 8-25 bottles/min | 20-60 bottles/min |

| Weight | 20 kg | / |

Successful case of jar filling machine

This customer from Ecuador runs a small jam-making workshop, primarily supplying natural, handmade jam to local supermarkets and e-commerce platforms.

They previously used manual packaging, which was not able to achieve accurate production. In order to reduce waste and ensure uniform and beautiful packaging, the customer sought an efficient, hygienic, and precise semi-automatic sauce filling machine suitable for high-viscosity jam.

“We use this machine to bottle different flavors of jam—mango, pineapple, and guava. The filling process is so great, and the labeling machine gives our bottles a more professional look. Our sales have increased since we improved our packaging!”

Differences between automatic and semi-automatic paste filling machines

| Model type | Manual paste filling machine | Automatic sauce filler |

| Operation | Requires manual bottle placement | Fully automatic process including bottle feeding, filling, capping, and labeling |

| Output | 300–800 bottles/hour | 2000–6000 bottles/hour |

| Price | Lower cost and economical | Higher investment but greater efficiency |

| Application scenario | Ideal for startups, small workshops, and handmade products | Suitable for medium to large factories and continuous production lines |

Applications of Taizy sauce can filling machine

This machine can not only make bottle filling(fluid or semi-fluid products such as ketchup, chili sauce, salad dressing, honey, etc.), but also fill (peanut butter, sesame paste, jam, etc., high viscosity materials).

Therefore, our sauce filling machine is very important in many food production and processing industries. Large-scale condiment factories, nut butter producers, and catering and food processing industries will use these fully automatic filling machines to expand production lines.

While small handicraft workshops will also purchase semi-automatic filling machines to improve production efficiency. This sauce filling machine is low-cost and only takes up little space, making it ideal for startup brands with limited budgets.

How to choose the right sauce filling machine for your business?

- Depend on your production scale: semi-automatic models can be used for small batches, while fully automatic models should be selected for large-scale production.

- Budget is also a key factor in investing in a business: semi-automatic models are more economical, while automatic models are cost-effective in the long run.

- Labor cost: If labor cost is high, fully automatic machines can save money, while semi-automatic machines are suitable for areas with lower labor costs.

- Technical requirements: You need to consider the degree of automation, cleaning convenience, and after-sales support.

Contact us for a free quota and production list!

If you are hesitating about choosing a reliable company to help with your packaging solutions, Taizy would like to provide you with the best service.

- We have a source factory to give you the most affordable price and the best quality.

- We have the most complete export experience, and our experienced sales staff can help you solve all the problems related to the machine.

- We have the most transparent process, from machine production to delivery. Every step is negotiated properly to meet all your needs.

Contact us for the latest quotes and more detailed product information now!

In addition to our sauce filling machine, we also provide: