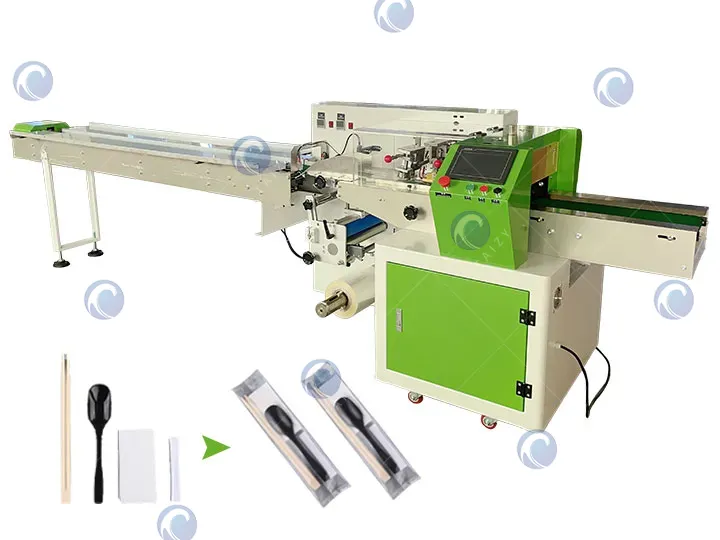

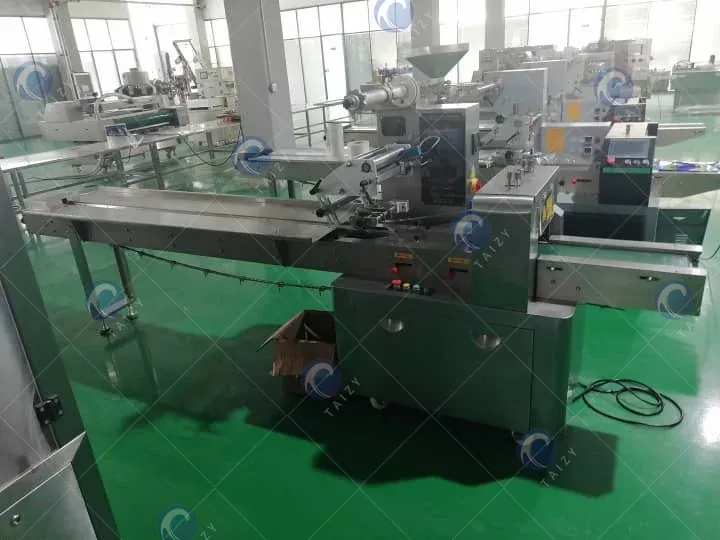

Taizy uppdaterar vår plastbestickförpackningsmaskin för att lösa fler förpackningsproblem för engångsartiklar. Den kan enkelt paketera engångshotellförbrukning (tandborste, comb, tvål), engångsbestick osv., med en kapacitet på 30-120 påsar/min.

Den uppdaterade maskinen använder servomotorteknik för att mer exakt klippa förpackningsstorleken efter produktens faktiska längd. Dess vägglängd sträcker sig från 90 till 600 mm, och dess kantlängd sträcker sig från 50 till 160 mm.

Om du inte är säker på om denna plastbestickförpackningsmaskin passar dig eller inte, kan du skicka bilder på dina produkter till oss. Vi kommer att ge dig perfekta förpackningslösningar.

Huvudfunktioner och fördelar med plastbesticksförpackningsmaskinen

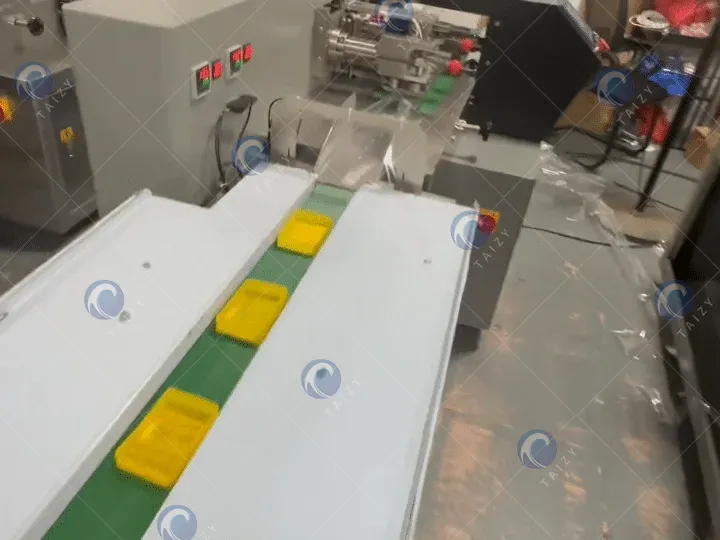

- Maskinen är utrustad med en bälte-transportör för att motstå att föremål fastnar och göra den enkel att rengöra när den är smutsig.

- Vägglängden behöver inte ställas manuellt. Den upptäcks och ställs automatiskt under drift. Den högkänsliga fotocellen spårar automatiskt och exakt i samarbete med skäraren för att perfekt kontrollera vägglängden.

- Med tre servostyrningar är den mekaniska strukturen hos Taizy plastbestickförpackningsmaskin enkel att underhållas, vilket leder till minskat slitage och längre livslängd.

- Den engångsbesticksförpackningsmaskinen använder en roterande förseglande kniv, och varje förseglingstemperatur kontrolleras oberoende, vilket gör den lämplig för förpackning av olika material, inklusive OPP, OPP/CPP, KOP/CPP och ALU-FILM.

Fungerande princip för Taizy-tableware wrapping maskin

Först måste besticken (sked, gaffel, pinnar, eller ett komplett set) placeras på matarföraren. Denna konvektor transporterar automatiskt och kontinuerligt besticken till filmförpackningsområdet.

Nästa, i tunnfilmsinslagsområdet, upptäcks besticken av fotoceller som justerar filmspänningen och positionen för att säkerställa exakt skärning och försegling.

Sedan passerar besticken genom formingområdet, där filmen viks runt produkten. En längsgående försegling enhet tätar botten eller baksidan av filmen och bildar en kontinuerlig rörformad säck.

Slutligen passerar filmen som innehåller besticken genom den tvärgående förseglingen och skäreg stations. uppvärmda förseglings käftar skapar samtidigt slutförseglingen och skärlinjen, vilket resulterar i individuella, helt förseglade förpackningar.

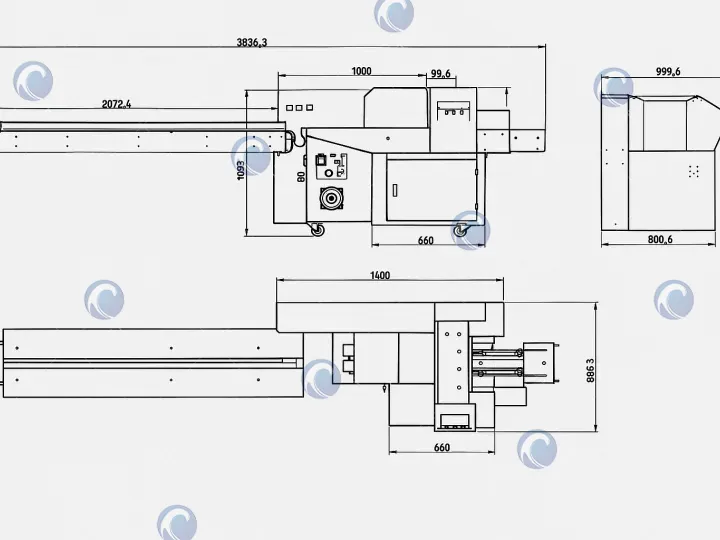

Modeller och parametrar för plastbestickförpackningsmaskinen

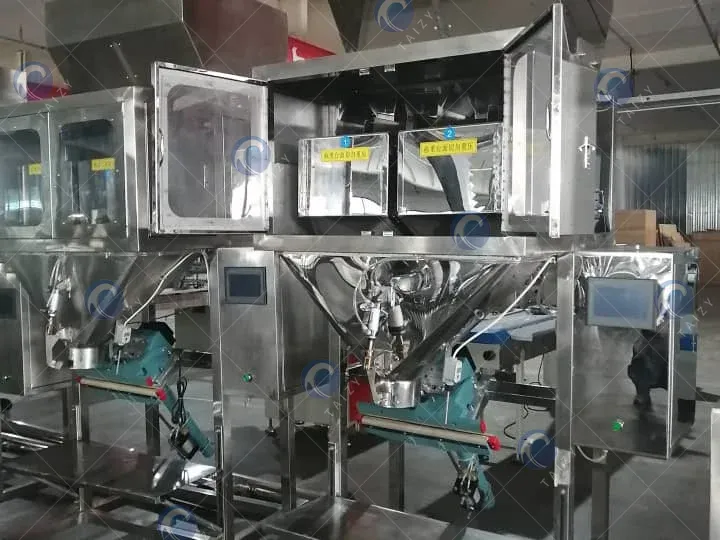

Denna maskin är huvudsakligen uppdelad i två modeller: filmrullningsmodell och filmrullned modell.

| Mfano | TZ-350X | TZ-350S |

| Upana wa filamu | 350 mm (Max) | 350 mm (Max) |

| Bag length | 90-600 mm | 65-190mm eller 120-280mm |

| Bag width | 30-160mm | 50-160mm |

| Urefu wa bidhaa | 70 mm (Max) | 60 mm (Max) |

| Dairamu ya rolli ya filamu | 320 mm (Max) | 320 mm (Max) |

| Kiwango cha ufungaji | 30-120bags/min | 25-120bags/min |

| Vifaa vya ufungaji | OPP,OPP/CPP,KOP/CPP,ALU-FILM | OPP,OPP/CPP,KOP/CPP,ALU-FILM |

| Nishati | 220V, 50/60Hz, 2.4KW | 220V, 50/60Hz, 2.6KW |

| Ukubwa wa mashine | 3836mm*890mm*1079mm | 4020mm*820mm*1450mm |

| Machine weight | 350Kg | 300Kg |

Användningsområden för engångsbesticksförpackningsmaskinen

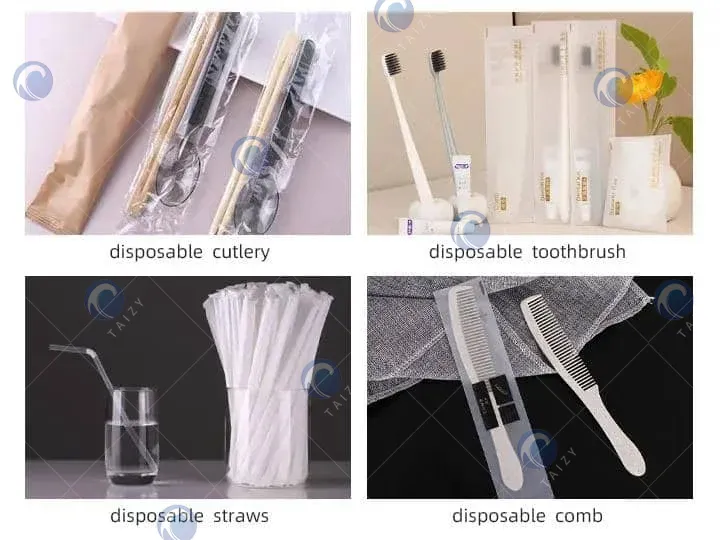

Förutom förpackningen av engångsbestick kan denna maskin även användas för självständig förpackning av hotellengångsartiklar, engångs-sugrör, medicinska engångsprodukter, etc.

Hotell behöver säkerställa hygien för varje gäst, så individuellt förpackade engångsartiklar har blivit en nödvändighet på hotell. Vissa hotellförbrukningsfabriker specialiserar sig på produktion och förpackning av engångsprodukter, som tandborstar, kamar, rakhyvlar, tvål och tofflor.

Uppskattningar för leverantörer av cateringtjänster och tillverkare av flygplansmåltider tillhandahåller engångstabletter-set (skedar, gafflar, pinnar, servetter, tandpetare) till restauranger, take-away och flygplanmåltider. Vår plastbesticksförpackningsmaskin kan perfekt lösa förpackningsproblemen för dessa produkter.

Dessutom används denna maskin för individuellt förpackning av engångsdagligvaror i fabriker som till exempel sugrör, plastknivar och hygienprodukter, vilket inte bara förbättrar förpackningseffektiviteten och minskar arbetskostnaderna utan också säkerställer hygieniska standarder under massproduktion.

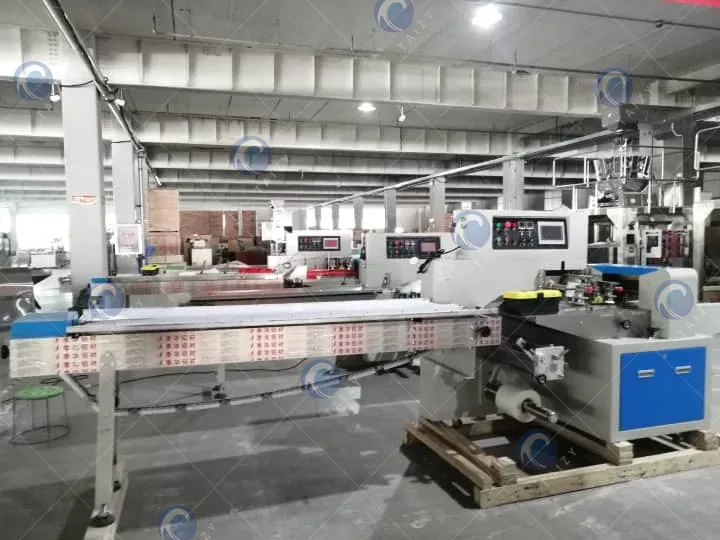

Varför välja denna plastbestickförpackningsmaskin för modern produktion?

Jämfört med manuell förpackning ökar denna tandborstförpackningsmaskin avsevärt produktionseffektiviteten och förpackningskonsistensen, vilket möjliggör kontinuerlig drift och uppfyller behoven av storvolymsproduktion av engångsprodukter.

Dessutom fullständigt automatiskt fyller, förpackar, förseglar och skär plastbestickförpackningsmaskinerna, vilket förhindrar kontaminering av mänsklig kontakt och säkerställer rena och hygieniska bestick.

För tillverkare och leverantörer av engångsprodukter minskar att ersätta manuell arbetskraft med maskiner arbetsinsatsen och produktionskostnaderna samtidigt som mänskliga fel elimineras och säkrar tätning och enhetlig utseende, vilket kraftigt ökar konkurrenskraften för produkten.

Taizys plastbesticksförpackningsmaskin stöder miljövänliga, biologiskt nedbrytbara film-material och anpassad tryck, vilket möter behoven hos vissa företag som vill anta miljötrender och personifiera sina varumärken.

Om du vill ha en fantastisk förpackningslösning för ditt företag, kommer Taizy gärna att ge dig de bästa idéerna. Tveka inte att kontakta oss om du vill få en gratis offert och mer detaljer om vår maskin!