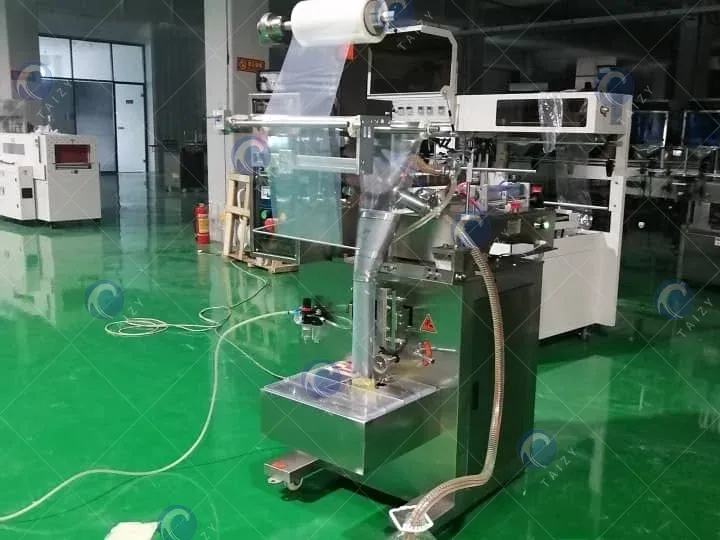

Taizy supports a semi auto paste filling machine for large-volume sauce filling(5-50 kg) with high accuracy of ±3%. It is made of stainless steel, which makes the machine widely used not only in the food industry but also in the chemical industry.

With a wide range of applications, including peanut butter, cooking oil, and pesticides, this hot-selling hand-operated paste filling machine has been exported to many countries around the such as India, Thailand, Mexico, and Morocco.

Highlight of semi auto paste filling machine

- Our machine features high-quality stainless steel construction, which is corrosion-resistant, hygienic, and durable, making it suitable for the food and chemical industries.

- This semi auto paste filling machine employs an electronic weighing system, ensuring precise control over product filling quality with an accuracy of ±3%.

- The filling range (5-50 kg) is easily adjustable to accommodate different container sizes and filling weights. What’s more, the filling weights can be preset for stable output.

- It can fill 50-100 barrels per hour, meeting the production needs of most small and medium-sized factories.

Application of Taizy industrial semi auto paste filling machine

This filling machine is particularly suitable for high-viscosity and semi-liquid foods such as ketchup, peanut butter, syrup, chocolate sauce, condensed milk, soy sauce, and vegetable oil, with a 5-50kg capacity suitable for kitchen and restaurant use.

This manual liquid paste filling machine is also widely used in the chemical and agricultural sectors for filling pesticides, lubricants, disinfectants, industrial adhesives, emulsions, and other non-flammable liquid chemicals. By using corrosion-resistant materials, it can efficiently handle acidic, alkaline, and oily liquids.

Parameters of hand-operated paste filling machine

| Power | AC220 V 50/60 Hz 1.5 KW |

| Filling range | 5–50 KG |

| Capacity | 50–100 drums/hour |

| Air consumption | 0.4 m³/min |

| Working pressure | 5–7 kg/cm² |

| Accuracy | ±3% |

| Weight | 150 KG |

| Dimensions | 1800×700×1600 mm |

This is the only new model we’ve released. We can also customize other models to meet your needs. Please contact our service staff for details!

How to choose the right sauce filling machine for your business?

Besides this type of semi auto paste filling machine, we also provide other models for small cans and bottles paste filling. which is perfect for 100-1000g solid or liquid filling. But how to choose the right machine for your business? Some points will give you some advice:

1. Choosing filling machines depends on the viscosity and flowability of the paste.

- For high-viscosity sauces with particles, such as chili sauce and peanut butter, a piston or pump-type filling machine requires a heating or mixing function.

- Medium-viscosity sauces, such as ketchup and honey, can be filled using a semi-automatic piston or gravity filling machine.

- Low-viscosity sauces, such as soy sauce, vinegar, or liquid seasonings, are suitable for liquid filling machines or gravity filling machines.

2. Choosing the appropriate level of automation is the basic thing

Select between semi-automatic and fully automatic filling machines based on production scale and labor resources.

- The semi auto paste filling machines are suitable for small and medium-sized factories. They are not only easy to operate but also versatile, flexibly filling various sauces.

- Fully automated filling production lines are more suitable for large-scale continuous production, integrating filling, capping, labeling, and conveying systems. While the investment is higher, it can significantly improve production efficiency and reduce labor costs.

If you have other needs, Taizy can also provide solutions based on your container size and material characteristics, making filling more efficient and packaging more exquisite, helping you easily improve productivity and product competitiveness.

3. Evaluate after-sales support and spare parts are also necessary

Choosing a good machine requires selecting a reliable manufacturer who will provide comprehensive spare parts supply and excellent after-sales service.

- If you want to reduce unnecessary capital investment in purchasing machinery, contacting a manufacturer with its own factory is the best option.

- If you want to reduce the various procedures associated with importing goods, finding an experienced company is the best choice.

Why choose Taizy manufacturer?

- We have our factory with a transparent machine producing progress. From the moment an order is placed, our dedicated customer service representative will provide real-time updates on the machine’s production process to ensure the authenticity of the production.

- With over a decade of export experience, we possess extensive expertise and complete export documentation, offering a one-stop service for worry-free shopping.

- Taizy has comprehensive after-sales service. Each machine will undergo testing and multiple layers of packaging before shipment. We also provide operation manuals and remote technical guidance to help you resolve any issues.

If you want to gain the latest quota and machine list, please consult us to get it!

In addition to this semi auto paste filling machine, we also support other paste filling machines with a filling range of 100-1000g, suiting small bottles and cans filling: Sauce Filling Machines For Canned Paste Packaging.