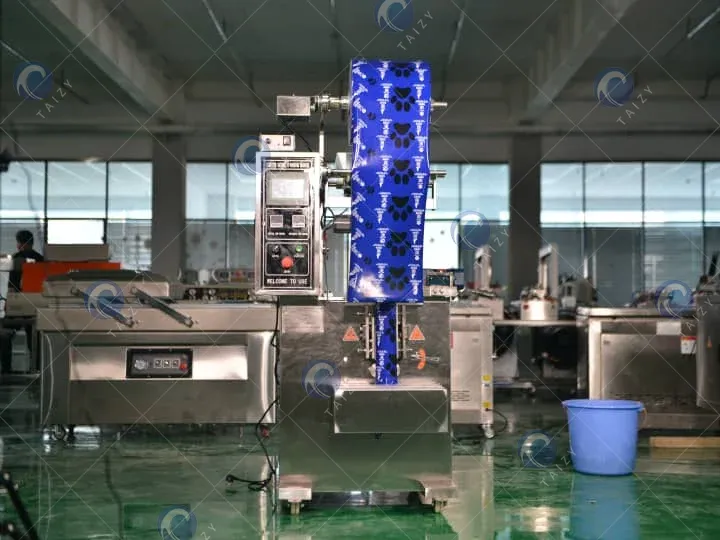

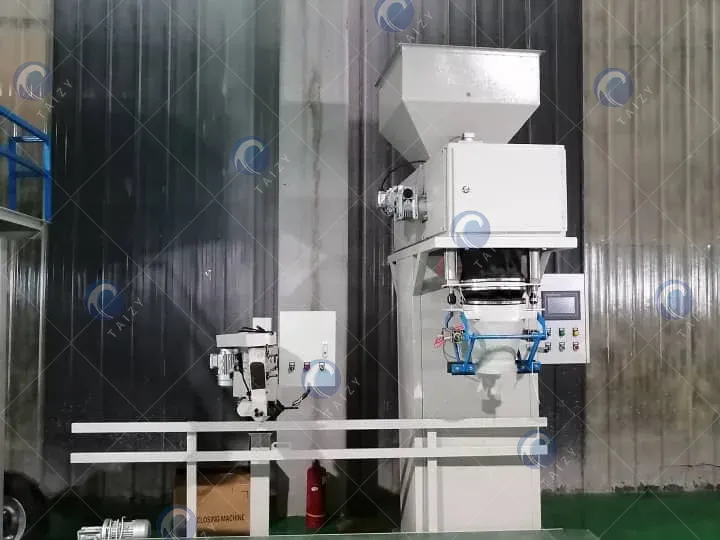

Упаковочная машина для кукурузной муки используется для упаковки больших мешков порошкообразных материалов, таких как мука, угольный порошок, порошок шпаклевки и т. д. Упаковочная машина может производить 15-60 мешков в минуту и может наполнять и упаковывать материалы в диапазоне 10-50 кг.

Особенности упаковочной машины для кукурузной муки

- Эта машина для заполнения порошка с шнековым механизмом является оснащенной программируемым контроллером, который необходим для установки требуемых параметров, таких как количество наполнения и длина мешка, и для формирования в установочном блоке, который может быть отображен.

- Ее система управления автоматически оптимизирует и сопоставляет каждое действие для достижения наилучшей скорости упаковки. Используя систему подачи с двойным шнеком с технологией цифрового преобразования частоты, она эффективно контролирует точность подачи.

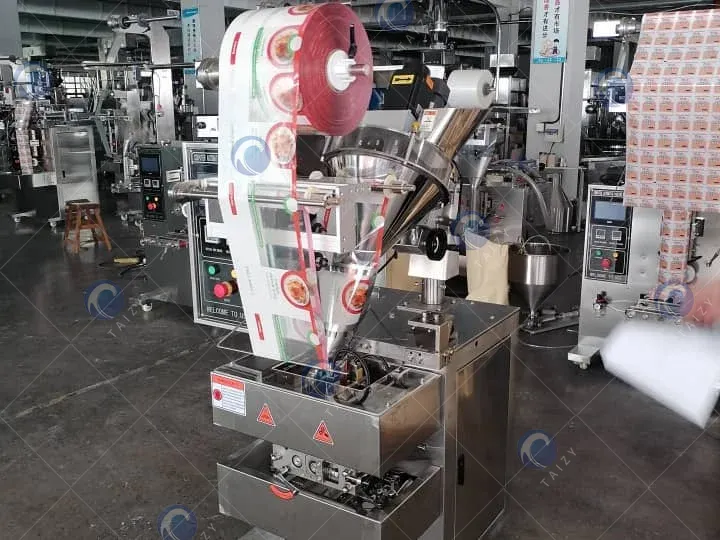

- Затем машина для упаковки кукурузной муки оснащена фотоэлектрической системой обнаружения. Она стабильна и надежна, обеспечивая целостность товарного знака упаковочного мешка.

- Двусторонняя термоупаковка и интеллектуальный контроль температуры обеспечивают надежное запечатывание без повреждения упаковки.

- The Механизм формирования мешков в стиле лацканов производит красивые, гладкие мешки.

- Доступны дополнительные диагональные запечатки и дизайн мешков с задним запечатыванием в виде подушки, максимально увеличивая применимость.

- Различные методы измерения включают объемные чаши, шнеки, насосы и электронные весы.

Конструкция упаковочной машины для порошка

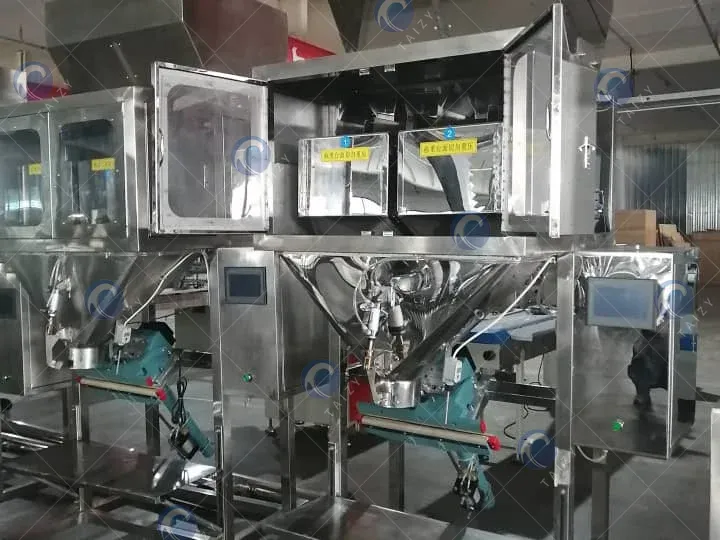

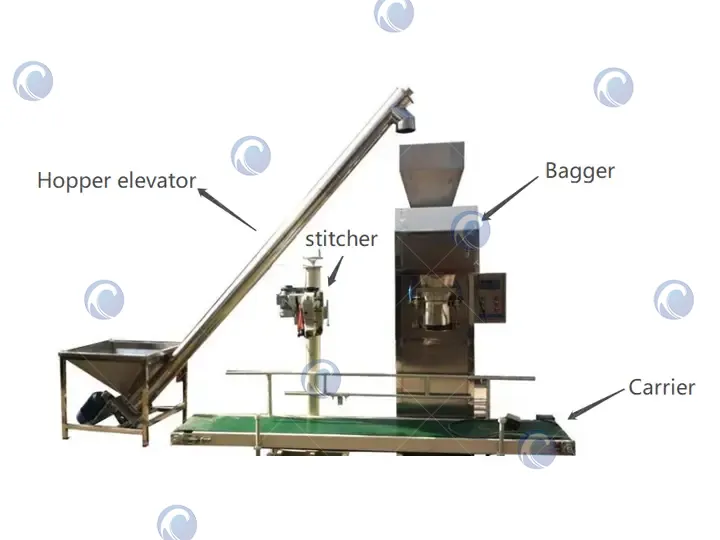

Упаковочная машина для кукурузной муки состоит из четырех основных частей.

- Во-первых, это основной блок упаковочной машины для кукурузной муки, изготовленный из нержавеющей стали марки 304, с импортным электрическим брендом, стабильный и долговечный.

- Во-вторых, это шнековый дозатор, поскольку он контактирует с материалом, используется материал из нержавеющей стали, привод от серводвигателя и высокая точность измерения.

- Далее идет подъемный шнек, который можно разбирать и чистить, что соответствует требованиям гигиены и безопасности пищевых продуктов и лекарств.

- Наконец, бункер для хранения и конвейер готовой продукции.

Применение фасовочной машины для порошка

Эта упаковочная машина для кукурузной муки подходит для упаковки пищевых продуктов (мука, сухое молоко, чайный порошок, дрожжевой порошок и т. д.), фармацевтических препаратов (тальк, лактоза и т. д.), химикатов (карбонат кальция, гидроксид кальция, тальк и т. д.), бытовой химии и других порошкообразных материалов.

В качестве упаковочных материалов для порошкообразных продуктов могут использоваться полиэстер/полиэтилен, полиэстер/алюминизированный полиэтилен, полиэстер/алюминиевая фольга/полиэтилен, бумага/полиэтилен, нейлон и другие термосклеиваемые композитные материалы.

Технические параметры фасовочной машины для порошка

| Производственная мощность | 15-60 мешков/мин |

| Диапазон измерения | 10-50 кг |

| Размер сумки | Д 80-360 мм Ш 100-250 мм |

| Общая мощность | 2,5 кВт |

| Напряжение питания | 220 В, 2,4 кВт |

| Вес машины | 550 кг |

Сколько стоит упаковочная машина для кукурузной муки?

Полная цена составит несколько тысяч долларов. И вот несколько моментов, которые помогут вам понять ее состав:

- Цена самой машины фиксирована, она была определена после разработки машины. Однако другие цены колеблются в зависимости от выбранной вами модели, требуемой услуги по индивидуальному заказу и других факторов.

- Стоимость таможенного оформления и транспортных услуг будет включена в общий счет.

- Машина будет строго упакована перед транспортировкой, что является частью стоимости обслуживания, но сумма невелика.

Кроме того, мы также предлагаем другие типы машин, такие как полуавтоматическая упаковочная машина для порошка, которая стоит дешевле этой.

Но упаковочная машина для кукурузной муки автоматическая, и ее эффективность работы выше. Если вы хотите сэкономить на расходах на рабочую силу, это лучший выбор. Даже несмотря на более высокую цену, она решает за вас множество мелких проблем и повышает вашу эффективность.

Значение влияет на цену. Поэтому выберите подходящий вариант для долгосрочного развития вашего бизнеса. Если вы хотите узнать подробности о оборудовании, оставьте сообщение и свяжитесь с нами, чтобы задать свои вопросы.

Как работают фасовочные машины для порошка?

Для работы этой машины требуется два этапа, и всего два рабочих могут выполнить всю работу.

После нажатия кнопки «Пуск» упаковочная машина для кукурузной муки готова к работе. Один человек управляет системой фасовки, помещая мешки на выход (есть независимые датчики подвески и фиксаторы, которые удерживают мешок для стабильной выгрузки).

А другой человек работает с машиной для запечатывания мешков. Если вы хотите убедиться в весе каждого продукта, эту проблему решат тензодатчики. Вот подробное видео ее рабочего процесса.

Мы также предлагаем малогабаритную упаковочную машину для порошка. Для получения более подробной информации вы можете перейти по ссылке: Вертикальная | Упаковочная машина для порошка или связаться с нами через WhatsApp. Мы ответим вам как можно скорее.