This liquid pouch filling machine is good for packaging liquid materials, such as water, milk, jelly, etc. Equipped with a quantitative device, it can accurately package products according to the set weight and can process 20-80 bags per minute.

Its bagging width has a range of 20-200mm, and the bagging length is between 50-250mm. The filling volume of the Taizy liquid pouch filling machine is 50-500 ml, which is suitable for large-batch, high-efficiency assembly line production.

Highlights of this liquid pouch filling machine

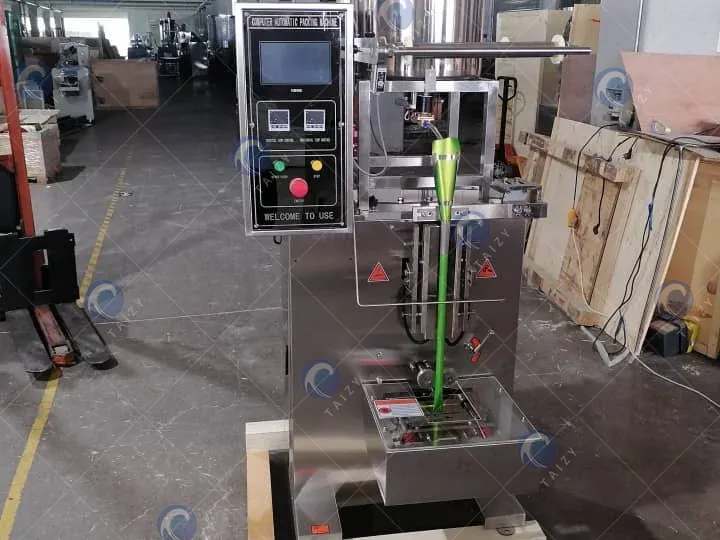

- Fully automated liquid bag filling machine completes, bag forming, date printing, quantitative filling, sealing and cutting, and other tasks to make your production line more streamlined and efficient.

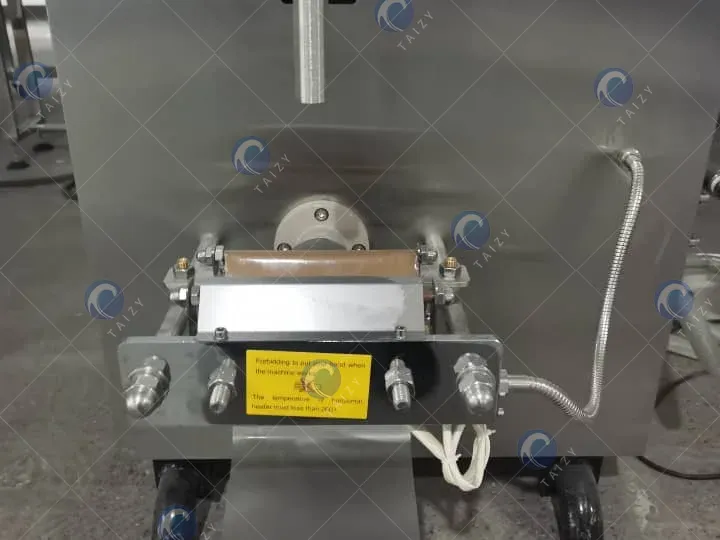

- The liquid pouch filling machine has extremely strict hygiene standards and is suitable for packaging high-quality products. Material contact parts, such as the metering pump, are made of food-grade stainless steel.

- This machine is equipped with a dual-CPU control system for easy operation and high efficiency. Its packaging speed can be adjusted directly via the controller without requiring machine downtime.

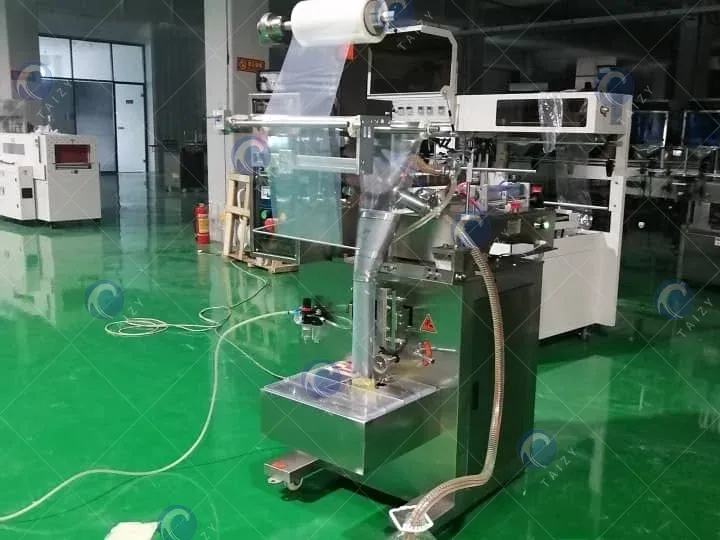

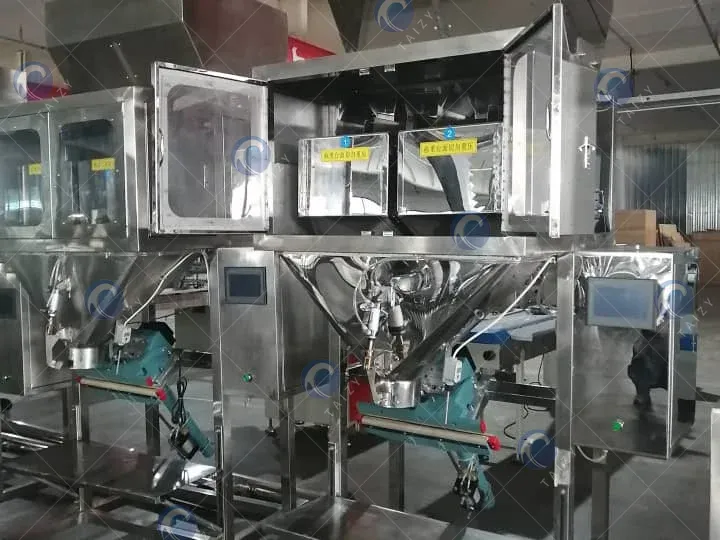

- Taizy liquid packing machine features a streamlined structure consisting of a forming unit, filling unit, sealing unit, and cutting unit. Operators can quickly master its operation with minimal training.

Important structural features of water pouch packing machine

This vertical packaging machine has a simple structure, which includes the film former, the control panel, the sealing device, the film pulling, the pump, and the discharge lower pallet. Here is its structural diagram.

Technical parameters and popular models of the liquid pouch filling machine

There are two model of this water pouch packing machine, and the following are their key technical parameters. If you have any other questions, please feel free to contact me.

| Model | TZ-1000 | TZ-2000 |

| Production speed | 2000-2200 bags/h | 1100-1300 bags/h |

| The packing capacity | 50-500 ml | 200-1000 ml |

| Bagging length | 50-150 mm | 50-250 mm |

| Bagging width | 40-150 mm | 40-175 mm |

| Power | 1.6 kw | 2.5 kw |

| Size | 880*760*1800 mm | 1050*850*2050 mm |

| Weight | 275 kg | 380 kg |

| Packaging film width | 100-330 mm | 100-380 mm |

Main function of automatic liquid packaging machine and its application

This machine is good at quantitative filling and sealing of liquid materials. We provide drinking water production lines for portable bagged water, to food processing plants for liquid seasoning packaging, and to some dairy farms that produce bagged milk.

All bagged liquid products that do not contain particles can be packaged using this machine. There are also many types of packaging bag styles available for you to choose from. Such as back seal, three-sided seal, four-sided seal, and other types of sealing ways.

There is also another type of liquid pouch packaging machine that can be used to package pure liquid with a stick bag, providing more packaging forms. They are TZ-320 and TZ-450, which fill and seal liquid products with low specific gravity.

Other popular liquid packaging machines in the same category

TZ-320 and TZ-450 have the same functions as SJ-1000 and SJ-2000. However, their maximum packaging volume ranges differ, and there are also differences in the bag sealing methods they can use. Here is a simple table for introducing the TZ-320 and TZ-320 liquid pouch filling machines.

| Model | TZ-320 |

| Packing speed | 20-60 bags/min |

| Packing granule | ≤200 g |

| Bag width | 25-145 mm |

| Film width | ≤15 cm |

| Power Consumption | 1.8 kw |

| Weight | 250 kg |

| Dimensions | 650*850*1850 mm |

| Model | TZ-450 |

| Packing speed | 30-80 bag/min |

| Packing granule | ≤1000 g |

| Bag width | 20-200 mm |

| Film width | ≤20.5 cm |

| Power Consumption | 2.2 kw |

| Weight | 420 kg |

| Dimensions | 750*750*2100 mm |

Note: Although the TZ model beverage packaging machine and the SJ model water pouch packing machine can both be used to bag liquid products, but TZ model has a heretical pump as a means of precise filling. So it will be more strict on the choice of material-pure liquid without granular.

In addition, we also provide a popsicle packaging machine, which is suitable for packaging composite film jelly bars, popsicles, and other pure liquid materials with good fluidity. The packaged product is in a drum shape, usually in the form of a back seal.

You can choose the machine based on different materials. But if you have no idea, just tell me your problems, and I will help you make the best choice!

The price of liquid pouch filling machine

This is one of the most frequently asked questions. Then I will tell you an approximate range of this liquid packaging machine. The overall price costs a few thousand dollars. There are three key things you must know, which are the main factors affecting prices:

1. The model you choose and the customized service you need. We know each model of machine must have a different price.

But what is the customized service? It is an additional service for individuals with specific requirements. For example, some of our clients will require that it be possible to equip it with a printer to code dates and other product information.

2. The transportation costs and import/export duty costs. If you don’t know the details about this, our company will be responsible for it and deliver the machines to your area.

The way of transportation also influences the real price, as we all know, an airport is more expensive than a ship, but it’s quicker. If you are an international trade expert and can solve the problems of customs clearance, then you can calculate which method is more cost-effective for you.

3. Packaging costs are also one part of the expenses, ensuring that your liquid pouch filling machine will be transported safely.

Our packaging consists of inner and outer packaging. The inner packaging is designed to prevent scratches and secure the machine. The outer packaging acts as a support to prevent external forces from striking and squeezing the machine, which is made of the most sturdy steel frame.

If you want to purchase this type of machine, consult me for more information and a discount.

We also provide paste packaging machines. Click the link to learn more details!