Diese Flüssigkeitsfüllmaschine kann 500–2000 Flaschen mit 500 ml Material pro Stunde füllen und ist damit hocheffizient. Sie bietet eine genaue Berechnung mit einer Füllabweichung von weniger als 1% für Volumen über 100 ml. Ihr Füllbereich liegt zwischen 500 und 2000 ml und erfüllt damit die meisten industriellen Getränkeabfüllanforderungen.

Gleichzeitig wird die Taizy-Flaschenfüllmaschine für Flüssigkeiten weit verbreitet zum Abfüllen von Flüssigkeiten, viskosen Flüssigkeiten, Pasten und Saucen in verschiedenen Branchen eingesetzt, darunter Lebensmittel, Medizin, Chemie, Drogerieprodukte, Öl, Tierarzneimittel, Pestizide und andere.

Warum entscheiden sich viele Lebensmittelverarbeiter für unsere Flüssigkeitsabfüllmaschine?

Die meisten unserer Kunden integrieren Flüssigkeits- und Pastefüllmaschinen in Lebensmittel- oder andere Produktionslinien. Aber warum wählen sie diese Art von Geräten? Hier einige Gründe:

- Die gesamte Maschine besteht aus SUS304-Material und entspricht den GMP-Standards. Sie schafft eine sterile Umgebung für die Lebensmittelproduktion und gewährleistet die Produktqualität.

- Durch den Einsatz eines importierten Servomotors zum Antrieb des Kolbenzylinders erreicht diese Flaschenfüllmaschine für Flüssigkeiten eine dosierte Abfüllung, genaue Füllmengen und eine Zählfunktion.

- Wenn Sie die Spezifikationen ändern oder das Füllvolumen anpassen möchten, können Sie dies direkt auf dem Touchscreen tun, was einfach und bequem ist. Sie wird auch mit Anleitungsvideos und Maschinenhandbüchern geliefert, sodass der Einstieg leicht fällt.

- Ausgestattet mit dem photoelektrischen System von Japan Panasonic kann sie die Positionierung der Flaschen beim Abfüllen genau erkennen und arbeitet nur, wenn Flaschen erkannt werden.

Verschiedene Typen von Flüssigkeitsabfüllmaschinen und deren technische Parameter

Es gibt zwei Typen von Füllmaschinen: Flüssigkeitsfüllmaschinen und Pastefüllmaschinen. Die Pastefüllmaschine hat zusätzlich lediglich einen Rührer im Vergleich zur Flüssigkeitsmaschine. Sie können die spezifische Füllmaschine entsprechend Ihren Materialien wählen.

Hier sind einige Parameter von ihnen mit unterschiedlichen Kapazitäten.

| Typ | AT-SFGZ-L4 | AT-SFGZ-L6 | AT-SFGZ-L8 | AT-SFGZ-L12 | AT-SFGZ-L16 |

| Fülldüse | 4 | 6 | 8 | 12 | 16 |

| Messbereich | 500-2000 ml | 500-2000 ml | 500-2000 ml | 500-2000 ml | 500-2000 ml |

| Füllgenauigkeit | ±1%(100 ml) | ±1%(100 ml) | ±1%(100 ml) | ±1%(100 ml) | ±1%(100 ml) |

| Produktionskapazität (basierend auf 500 Millilitern) | 500-1000 Flaschen/h | 800-1600 Flaschen/h | 1000-2000 Flaschen/h | 1500-3000 Flaschen/h | 2000-4000 Flaschen/h |

| Luftversorgungsdruck | 0.5-0.7 mpa | 0.5-0.7 mpa | 0.5-0.7 mpa | 0.5-0.7 mpa | 0.5-0.7 mpa |

| Luftverbrauch | 20 L/t | 30 L/t | 40 L/t | 60 L/t | 100 L/t |

| Gesamtleistung | 2.0 KW | 2.0 KW | 2.0 KW | 2.0 KW | 2.0 KW |

| Gewicht | 300 kg | 400 kg | 500 kg | 700 kg | 900 kg |

| Gesamtmaße | 400*110*210 cm | 400*110*230 cm | 400*115*230 cm | 600*100*230 cm | 600*100*230 cm |

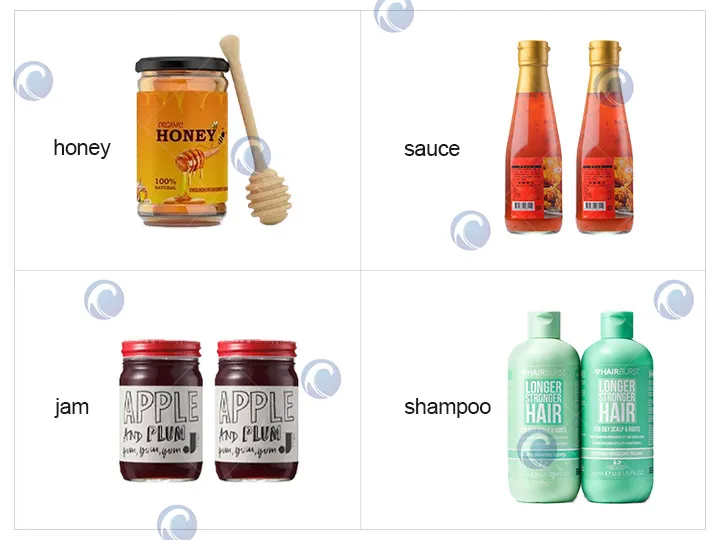

Anwendungsbereich dieser Flüssigkeitsflaschen-Abfüllmaschine

Wenn Sie dessen Anwendungsbereich kennen möchten, müssen zwei Bedingungen erfüllt sein:

- Der Behälter kann Flaschen, Dosen oder Fässer sein.

- Die Materialien sind fließende Flüssigkeiten oder Pasten.

Wenn diese beiden Prinzipien erfüllt sind, können Sie eine geeignete Maschine auswählen.

Anwendungsbereich der Flüssigkeitsflaschenfüllmaschine:

- Lebensmittelindustrie: Wasser, Saft, Öl, Essig, Milchprodukte usw.

- Pharmazeutische Industrie: Abfüllung von flüssigen Medikamenten, Sirupen, oralen Lösungen usw.

- Tägliche chemische Industrie: Abfüllung von flüssigen Reinigungsmitteln, Shampoos, Conditionern, Lotionen, Flüssigseifen, Desinfektionsmitteln usw.

Anwendungsbereich der Flaschenfüllmaschine für Flaschen:

- Lebensmittelindustrie: Erdnussbutter, Marmelade, Honig, Tomatenpaste, Chilisauce, Sesampaste usw.

- Pharmazeutische Industrie: Salben, Gele, Cremes, Kräuterextrakte usw.

- Tägliche chemische Industrie: Gesichtcremes, Körperlotionen, Haarconditioner, Zahnpasta, Handdesinfektionsgele usw.

Detaillierte Komponenten der Flüssigkeitsflaschen-Abfüllmaschine

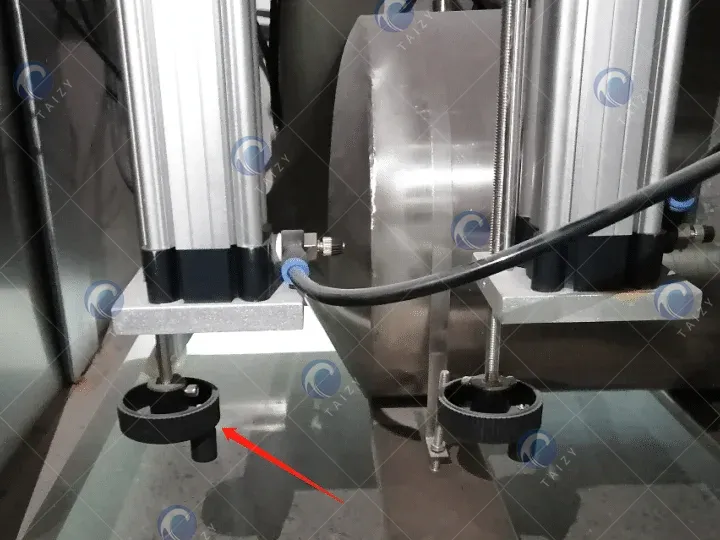

1. Produktzuführband: Die Standardbreite beträgt 101 mm, Anpassungen sind möglich.

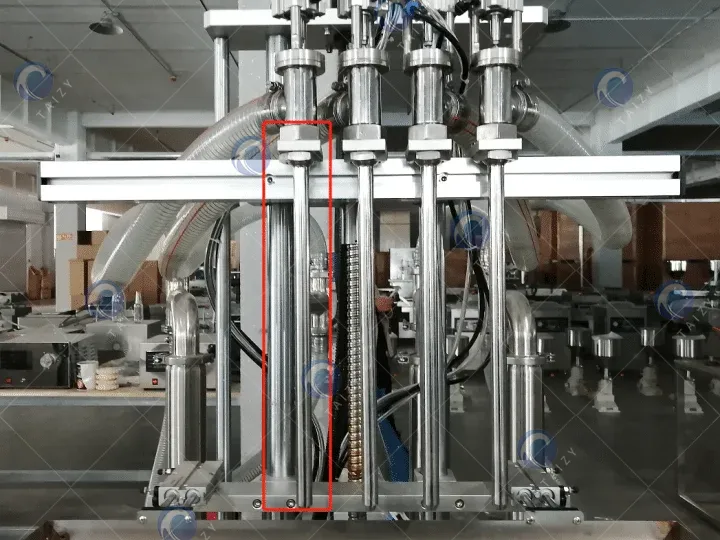

2. Fülldüsen: Zwei Längen sind verfügbar. Die längere ist beim Befüllen näher am Flaschenboden als die kürzere. Sie kann Schaum vermeiden und Dichtungsprobleme effektiv verhindern.

3. Rührwerk ist immer anwendbar für Pastenfüllungen in Flaschen oder Dosen (nur bei Flüssigfüllungen ist dieses Gerät nicht erforderlich). Es kann ausgestattet werden mit:

- Diese Heizfunktion dient zur Verhinderung von Verfestigung.

- Die Rührwelle verhindert ungleichmäßiges Befüllen von Flüssigkeiten mit Partikeln.

- Ein Flüssigkeitsstandsschwimmer zur automatischen Erfassung der verbleibenden Materialmenge im Tank.

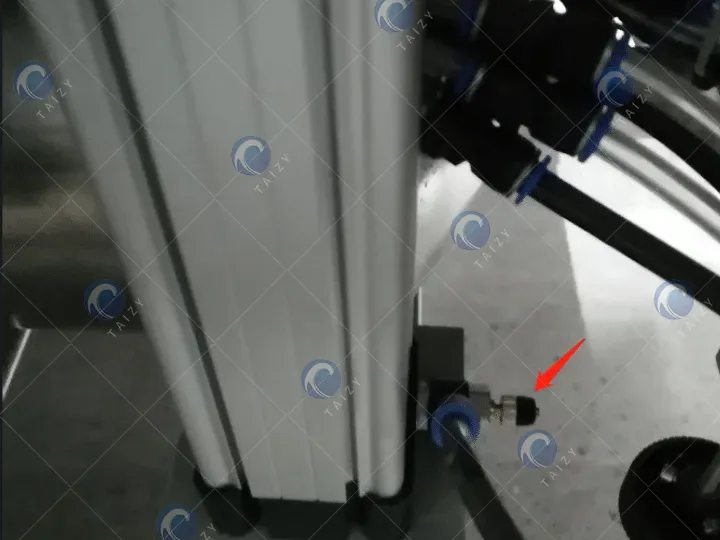

4. Durchflussregelventil: Es steuert den Zylinder zur Anpassung des Füllvolumens jeder Flasche.

5. Druckregelventil: Reguliert die Durchflussmenge, um die Abfüllgeschwindigkeit zu steuern.

Aufgerüstete vollautomatische Saftproduktionslinie

Für hochwertige und vollautomatische Produktverarbeitung bieten wir außerdem eine Füllproduktionslinie an.

Sie umfasst einen Aufzug-Kappen-Sortierer, eine Flaschenfüllmaschine für Flüssigkeiten, eine automatische Verschließmaschine, ein automatisches Förderband, eine automatische Etikettiermaschine und eine Datencodiermaschine.

1. Aufzug-Deckel-Sortierer

Es wird in der unterstützenden Ausrüstung der Abfülllinie verwendet und seine Hauptfunktion ist das automatische Sortieren und Platzieren von Verschlüssen.

| Stromversorgung | AC 220 V/50 Hz |

| Anwendbarer Deckeldurchmesser | 30–60 mm |

| Arbeitsluftdruck | 0.5–0.8 MPa |

| Gewicht | 85 kg |

| Produktionskapazität | 25–65 Stk/min |

| Größe | 800 × 800 × 2100 mm |

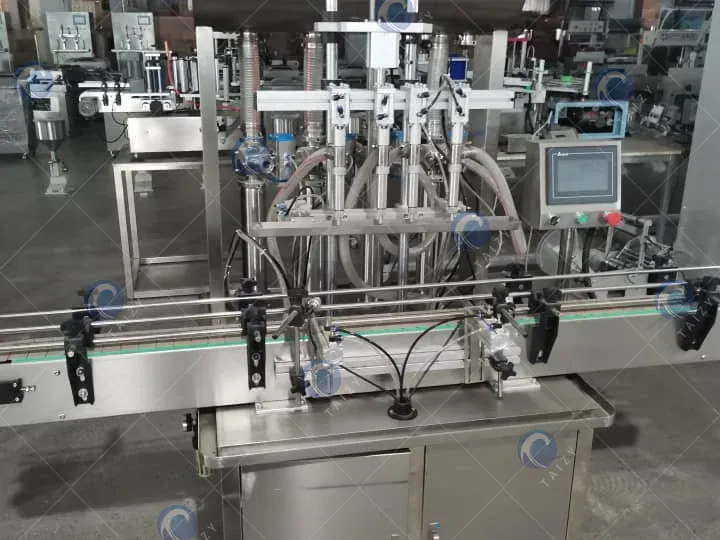

2. 6-köpfige vollautomatische Flüssigkeitsabfüllmaschine

Die Füllmethode verwendet das Kolben-Selbstansaugprinzip und kann breit in der automatischen Verpackungsproduktion von Saft/Getränken eingesetzt werden.

| Füllbereich | 100–500 ml |

| Füllgeschwindigkeit | 1300–1500 Flaschen/Stunde (basierend auf 500 ml/Flasche) |

| Füllgenauigkeit | ±1 g |

| Nennspannung | 3-phasig 380 V |

| Nennleistung | 3.2 kW |

| Arbeitsluftdruck | 0.6–0.8 MPa |

| Gewicht | 800 kg |

| Trichterkapazität | 45–70 kg |

| Größe | 1800 × 950 × 2150 mm |

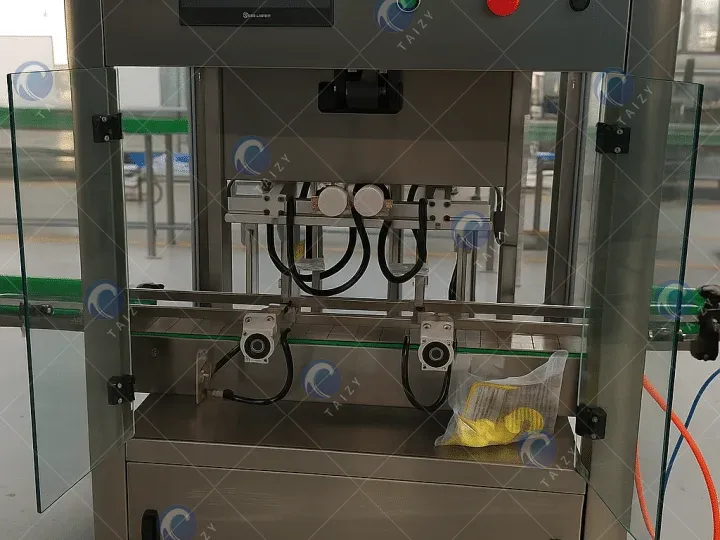

3. Tomatic-Verschließmaschine

Sie ist kompatibel mit verschiedenen Flaschenarten, sodass beim Wechsel der Flaschensorten keine Zubehörteile ausgetauscht werden müssen. Diese Eigenschaft mit schneller Verschließgeschwindigkeit und geringen Kosten erfüllt die meisten Anforderungen automatisierter Produktion in Unternehmen.

| Stromversorgung | AC 220 V/50 Hz |

| Verschlusshöhe der Flasche | 80–150 mm |

| Anwendbarer Deckeldurchmesser | 50–70 mm |

| Anwendbarer Flaschendurchmesser | 50–80 mm |

| Arbeitsluftdruck | 0.5–0.8 MPa |

| Gewicht | 350 kg |

| Produktionskapazität | 30–45 Flaschen/min |

| Größe | 800 × 900 × 1900 mm |

| Fördererhöhe | 800 ± 50 mm (einstellbar gemäß Produktionslinie des Kunden) |

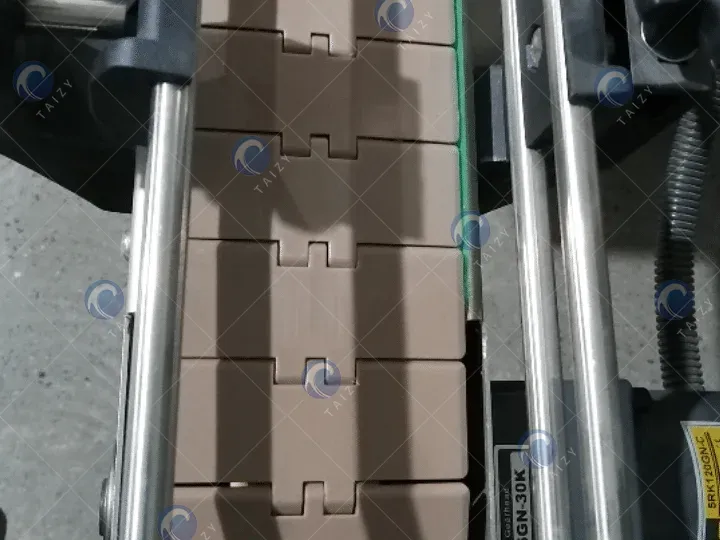

4. Automatisches Förderband

Die Förderkette besteht aus einem POM-Kettenband. Sie reduziert effektiv die körperliche Belastung manueller Handhabung und realisiert die Automatisierung der Produktion.

| Förderbandbreite | 82.6 mm |

| Fördergeschwindigkeit | 2–6 m/s |

| Nennspannung | 3-phasig 380 V |

| Geschwindigkeitsregelsystem | Frequenzumrichter (Drehzahlregelung) |

| Machine weight | 210 kg |

| Höhe über dem Boden | 850 mm ± 50 mm (kundenspezifisch auf Anfrage) |

| Kettenbandmaterial | SUS304 Edelstahl |

5. Automatische Etikettiermaschine

Die Etikettierposition und der Anschlag sind je nach Größe des zu etikettierenden Objekts einstellbar, sodass mehrere Produkte mit derselben Maschine etikettiert werden können.

| Etikettiergeschwindigkeit | 25–65 Flaschen/min |

| Etikettiergenauigkeit | ±1.5 mm |

| Etikettenzufuhrgeschwindigkeit | 3–50 m/min |

| Fördergeschwindigkeit | 5–30 m/min |

| Größe | 2400 × 1400 × 1780 mm |

| Anwendbare Etiketten | Selbstklebende einreihige Rollenetiketten (transparent/undurchsichtig); halbtransparentes Glaspapier als Träger; (Etikettenrollen Innendurchmesser: φ76.2 mm; max. Außendurchmesser: φ340 mm; Trägerpapierbreite: 16–200 mm) |

| Gewicht | 260 kg |

| Stromversorgung | AC 220V ±5%, 50/60 Hz |

| Luftversorgung | 0.4–0.7 MPa |

| Betriebstemperatur | 0–50 ℃ |

| Betriebsfeuchte | 15–90% RH |

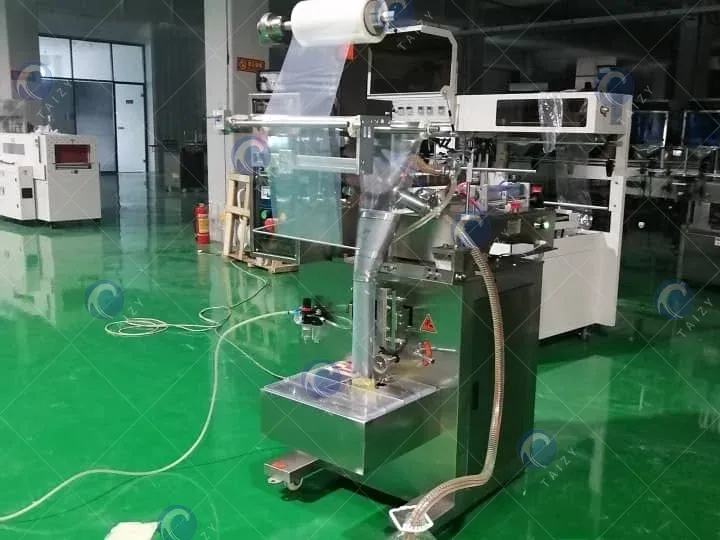

6. Datums-Kennzeichnungsmaschine

Sie kann Produktionsdatum/-zeit, Verfallsdatum, Chargennummer, Grafiken, LOGO und andere Formate drucken.

| Druckhöhe | Einstellbar 1–15 mm |

| Druckzeilen | 1–4 Zeilen, einstellbar |

| Schriftoptionen | 5×8, 8×8, 12×8, 16×16, 24×24 (auf Anfrage anpassbar) |

| Druckgeschwindigkeit | Bis zu 128 m/min (einzeilig hohe Geschwindigkeit) |

| Zeichenerweiterung der Breite | Bis zu 9× Vergrößerung |

| Druckkopfgröße | 180 × 43 × 44 mm |

| Stromversorgung | 110–240 V, 50/60 Hz |

| Betriebstemperatur | 5–45 ℃ (35–100 ℉) |

| Betriebsfeuchte | ≤90% RH, nicht kondensierend |

| Maschinengröße | 555 × 300 × 320 mm |

Wenn Sie mehr über diese Produktionslinie erfahren möchten, senden Sie mir eine Nachricht. Ich werde Ihre Frage so schnell wie möglich beantworten.

Neben dieser Art von Flaschenfüllmaschine für Flüssigkeiten bieten wir auch halbautomatische Füllmaschinen und Rotary-Füllmaschinen an, die ebenfalls für das Abfüllen von Flüssigkeiten geeignet sind.

Wenn Sie weitere Details zu anderen Informationen wünschen, rufen Sie mich an oder senden Sie eine E-Mail, und ich antworte so schnell wie möglich.