Rotary cup filling and sealing machine includes the whole process of packing cup yogurt. Its filling and sealing speed is several times faster than manual or semi-automatic, and it can finish 800-1800 cups every hour.

The yogurt cup filling sealing machine is made of stainless steel, which not only effectively prevents bacterial growth and contamination during the production process but also is easy to maintain and clean after use.

What are the significant advantages of the yogurt packaging machine?

- This yogurt packaging machine is a fully automatic packaging production line that integrates automatic cup feeding, filling, sealing, and cup discharging. It greatly saves labor and increases commodity profits.

- We choose SS304 as the material for the contacting material part, and use SS201 to make the machine body. The purpose of our design is to reduce costs while ensuring quality and bringing better preferential prices to our customers.

- Equipped with well-known brands of components in Japan and China, the automatic cup filling sealing machine quality is trustworthy, with a low failure rate and a long service life.

- We offer a wide range of custom services, including machine installation (such as date printing) and cup size customization. Next, I will explain the customized service in detail.

Special customization service of the yogurt cup filling and sealing machine

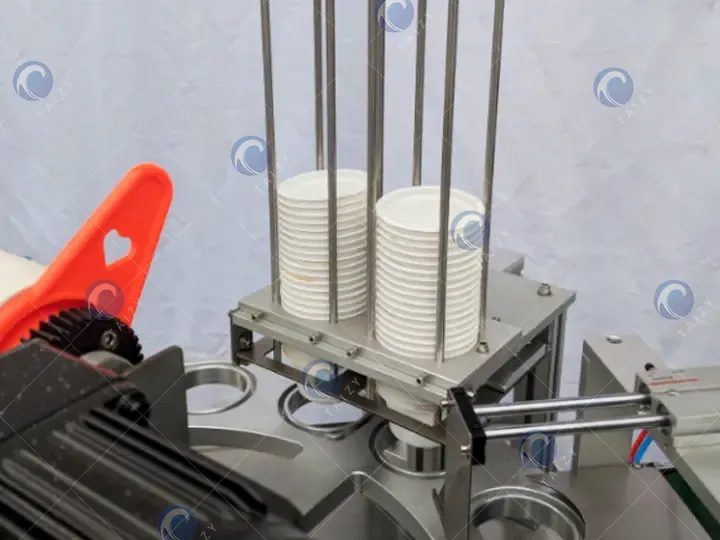

- The rotary table can be customized depending on the size of cups you need. (Note: Measure the diameter of the cup to determine the customization requirements. Cups of the same diameter but different heights fit the same mould.)

- If the yogurt contains particles, an agitator can be arranged to prevent solid sedimentation and uneven filling. For some other materials that tend to solidify, the agitator can maintain their fluidity for easy filling.

- We also provide the installation of a date coder. It can be applied for coding data, product descriptions, etc.

- Besides yogurt, cup filling and sealing machines can also pack liquid coffee and bulk nuts. But different materials need other customized filling systems.

Main functional structure of the cup cone filling machine

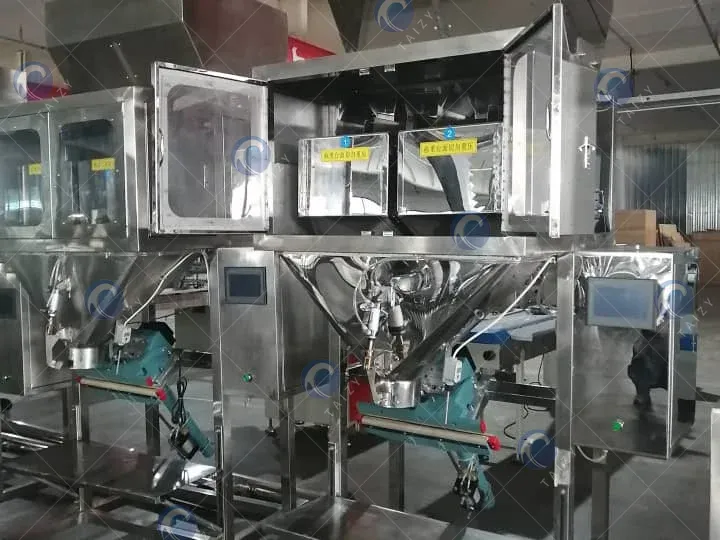

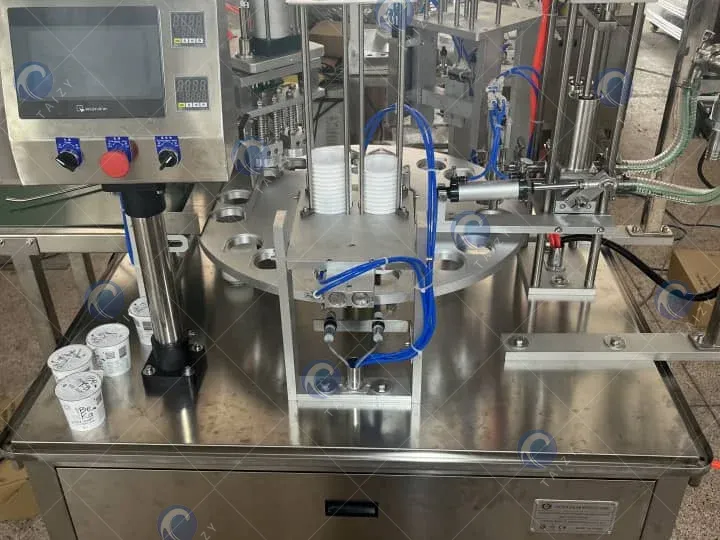

A cup filling and sealing machine mainly consists of a transmission and mold traction system, an automatic cup placement system, an automatic filling system, a lidding film system, a sealing system, and a cup sorting and dispensing system.

- Transmission and mold traction system comprises a drive motor, a reducer, a stable transmission device, a traction transmission chain, a positioning device, and an aluminum template.

- Automatic cup placement system is easier than other parts, which is mainly done by pneumatic devices.

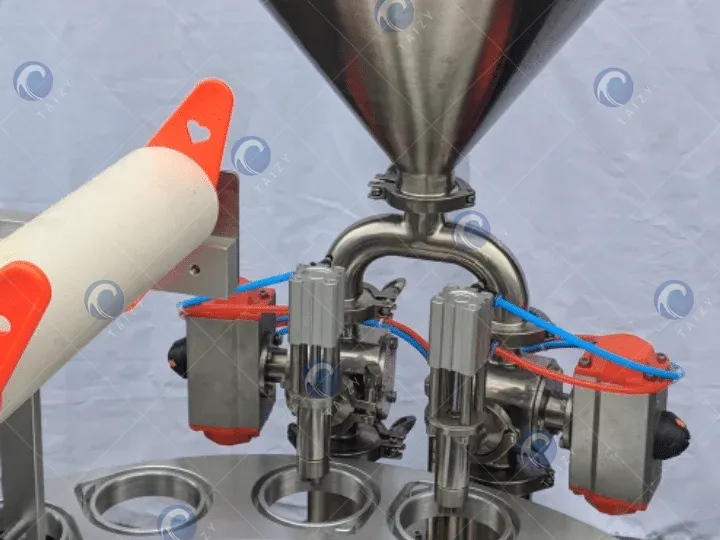

- Automatic filling system is used to control the single filling volume, which can be adjusted from 50-500ml.

- Lidding film system uses a starting device to ensure the accuracy of film placement. Two types of film systems: roll film and sheet film, and you can choose it according to the packaging effect you want to achieve.

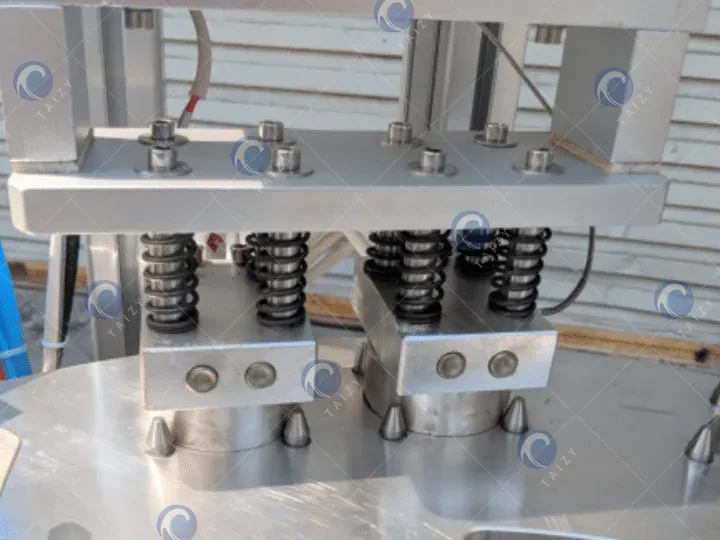

- The sealing system of the yogurt cup filling and sealing machine includes a heating and temperature control unit, temperature sensors, a sealing mechanism with heat sealing plates and heads, and a pneumatic actuator.

- Cup sorting dispensing system is always equipped with a conveyor belt to arrange products and send them out of the cup cone filling machine.

Different models and specific parameters of the rotary cup filler and sealer

The models of this cup filling and sealing machine are divided into two types: the rotary table type(including single-outlet and double-outlet) and the linear type(which can produce multiple products at one time).

The following are their detailed parameters.

| Model | Single-outlet | Double-outlet |

| Power | 1.5 KW | 2.5 KW |

| Production capacity | 800-900 cups/hour (one cup at a time) | 1600-1800 cups/hour (two cups at a time) |

| Dimension | 1100*1000*1300 mm | 1220*1220*1600 mm |

| Weight | 200 kg | 300 kg |

| Voltage | 220 V/50 Hz(can be customized) | 220 V/50 Hz(can be customized) |

| Working air pressure | 0.6-0.8 Mpa | 0.6-0.8 Mpa |

Note: Working air pressure needs to be equipped with an additional air compressor.

FAQ of the automatic cup filling and sealing machine

I want to fill two products with different diameters. Can I get a custom mold?

Yes, we provide customized services. We do not recommend it, because the mould is a complete part of the whole filling system. So if you want to change it, it is troublesome to reinstall and uninstall every time.

If the yogurt I want to fill contains solid particles, will this machine still work?

Yes, we can adopt an agitator for you to make the filling more fluent, and the solid particles have uniform content in each cup.

Can it be equipped with a printing device?

Yes, if you need it, we can install a date coder for you. And we will adjust its position to meet your needs.

Are there any other applications for this cup filling and sealing machine?

You can also use it to fill and seal liquid coffee, bulk nuts, etc. But different products need extra customized parts.

If you have any other problems with this yogurt cup filling and sealing machine, don’t hesitate to contact us!

If you want to produce bagged yogurt, I will introduce this machine to you: the paste packaging machine. If you want to know more details, click the link to get it.