يمكن لهذه الماكينة تعبئة 500-2000 زجاجة من مادة 500 مل في الساعة، مما يوفر كفاءة عالية. توفر حسابًا دقيقًا، مع خطأ تعبئة أقل من 1% للأحجام التي تزيد عن 100 مل. نطاق التعبئة الخاص بها من 500 إلى 2000 مل، مما يلبي معظم احتياجات تعبئة المشروبات الصناعية.

في هذه الأثناء، تستخدم آلة تعبئة الزجاجات السائلة من Taizy على نطاق واسع في تعبئة السوائل، والسوائل اللزجة، والمعاجين، والصلصات في مختلف الصناعات، بما في ذلك الأغذية، والأدوية، والمواد الكيميائية، والكيماويات اليومية، والزيوت، والأدوية البيطرية، والمبيدات الحشرية، وغيرها.

لماذا يختار العديد من مصنعي الأغذية آلة التعبئة السائلة الخاصة بنا؟

يضع معظم عملائنا آلات تعبئة السوائل والمعاجين في خطوط إنتاج الأغذية أو أنواع أخرى. ولكن لماذا اختاروا هذا النوع من المعدات؟ إليك بعض الأسباب:

- الآلة بأكملها مصنوعة من مادة SUS304، والتي تتوافق مع معايير GMP. إنها تخلق بيئة معقمة لإنتاج الأغذية وتضمن جودة المنتج.

- باستخدام محرك سيرفو مستورد لقيادة أسطوانة المكبس، تحقق آلة تعبئة الزجاجات السائلة هذه تعبئة بالقياس، وحجم تعبئة دقيق، ووظيفة عد.

- إذا كنت ترغب في تغيير المواصفات أو ضبط حجم التعبئة، يمكنك القيام بذلك مباشرة على شاشة اللمس، وهو أمر بسيط ومريح. تأتي أيضًا مع مقاطع فيديو تعليمية وأدلة للماكينة، مما يجعل البدء في استخدامها سهلاً.

- مزودة بنظام باناسونيك الكهروضوئي الياباني، يمكنها تحديد حالة تحديد المواقع لزجاجات التعبئة بدقة، ولن تعمل إلا عند التعرف على الزجاجات.

أنواع مختلفة من آلات تعبئة السوائل ومعاييرها الفنية

هناك نوعان من آلات التعبئة: آلات تعبئة السوائل وآلات تعبئة المعجون. تحتوي آلة تعبئة المعجون على خلاط إضافي واحد فقط مقارنة بآلة تعبئة السوائل. ويمكنك اختيار آلة التعبئة المحددة للمواد الخاصة بك.

إليك بعض المعلمات الخاصة بها بسعات مختلفة.

| يكتب | AT-SFGZ-L4 | AT-SFGZ-L6 | AT-SFGZ-L8 | AT-SFGZ-L12 | AT-SFGZ-L16 |

| فوهة التعبئة | 4 | 6 | 8 | 12 | 16 |

| نطاق القياس | 500-2000 مل | 500-2000 مل | 500-2000 مل | 500-2000 مل | 500-2000 مل |

| دقة التعبئة | ±1% (100 مل) | ±1% (100 مل) | ±1% (100 مل) | ±1% (100 مل) | ±1% (100 مل) |

| قدرة الإنتاج (بناءً على 500 مل) | 500-1000 زجاجة/ساعة | 800-1600 زجاجة/ساعة | 1000-2000 زجاجة/ساعة | 1500-3000 زجاجة/ساعة | 2000-4000 زجاجة/ساعة |

| ضغط إمداد الهواء | 0.5-0.7 ميجا باسكال | 0.5-0.7 ميجا باسكال | 0.5-0.7 ميجا باسكال | 0.5-0.7 ميجا باسكال | 0.5-0.7 ميجا باسكال |

| استهلاك الهواء | 20 لتر/ساعة | 30 لتر/ساعة | 40 لتر/ساعة | 60 لتر/ساعة | 100 لتر/ساعة |

| الطاقة الإجمالية | 2.0 كيلو واط | 2.0 كيلو واط | 2.0 كيلو واط | 2.0 كيلو واط | 2.0 كيلو واط |

| وزن | 300 كجم | 400 كجم | 500 كجم | 700 كجم | 900 كجم |

| الأبعاد الكلية | 400*110*210 سم | 400*110*230 سم | 400*115*230 سم | 600*100*230 سم | 600*100*230 سم |

نطاق تطبيق آلة تعبئة الزجاجات السائلة هذه

إذا كنت تريد معرفة نطاق تطبيقها، فأنت بحاجة إلى استيفاء شرطين:

- يمكن أن تكون الحاوية زجاجات أو علبًا أو براميل.

- المواد عبارة عن سائل متدفق أو معجون.

لذلك، بعد استيفاء هذين المبدأين، يمكنك اختيار آلة مناسبة.

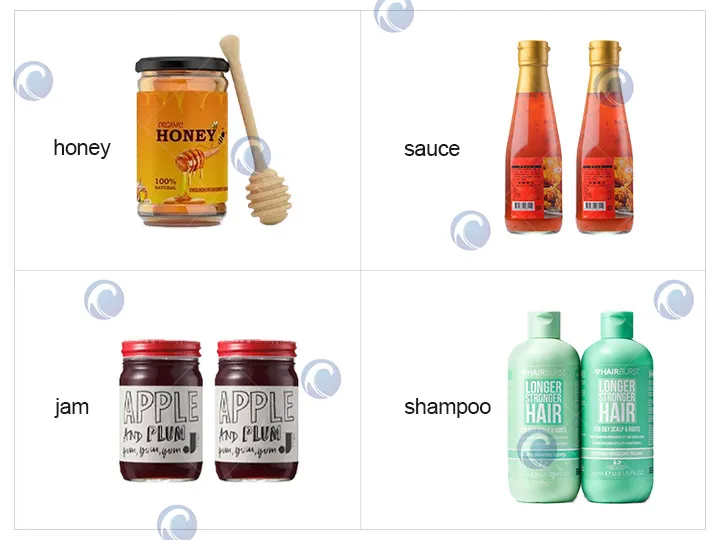

نطاق تطبيق آلة تعبئة الزجاجات السائلة:

- الصناعات الغذائية: الماء، العصير، الزيت، الخل، منتجات الألبان، إلخ.

- الصناعات الدوائية: تعبئة الأدوية السائلة، الشراب، المحاليل الفموية، إلخ.

- صناعة الكيماويات اليومية: تعبئة منظفات سائلة، شامبو، بلسم، لوشن، صابون سائل، مطهرات، إلخ.

نطاق تطبيق آلة تعبئة الزجاجات بالمعجون:

- الصناعات الغذائية: زبدة الفول السوداني، المربى، العسل، معجون الطماطم، صلصة الفلفل الحار، معجون السمسم، إلخ.

- الصناعات الدوائية: المراهم، الجل، الكريمات، المستخلصات العشبية، إلخ.

- صناعة الكيماويات اليومية: كريمات الوجه، لوشن الجسم، بلسم الشعر، معجون الأسنان، جل معقم اليدين، إلخ.

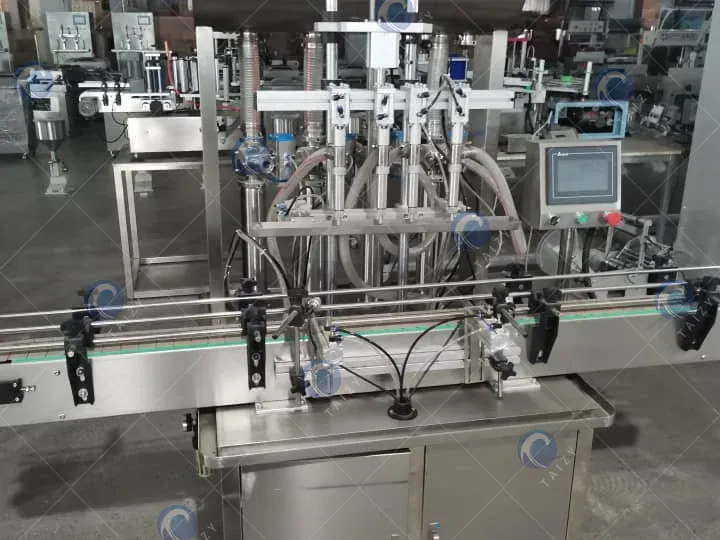

المكونات التفصيلية لآلة تعبئة الزجاجات السائلة

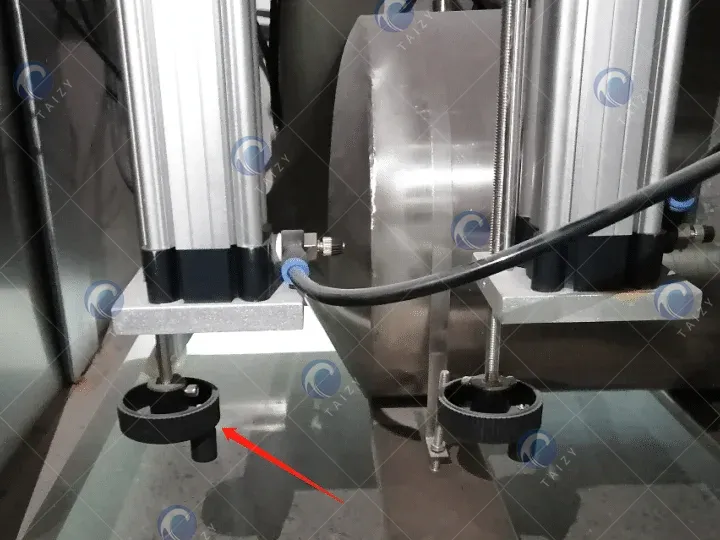

1. ناقل إدخال المنتج: العرض الافتراضي هو 101 مم، والتخصيص مقبول.

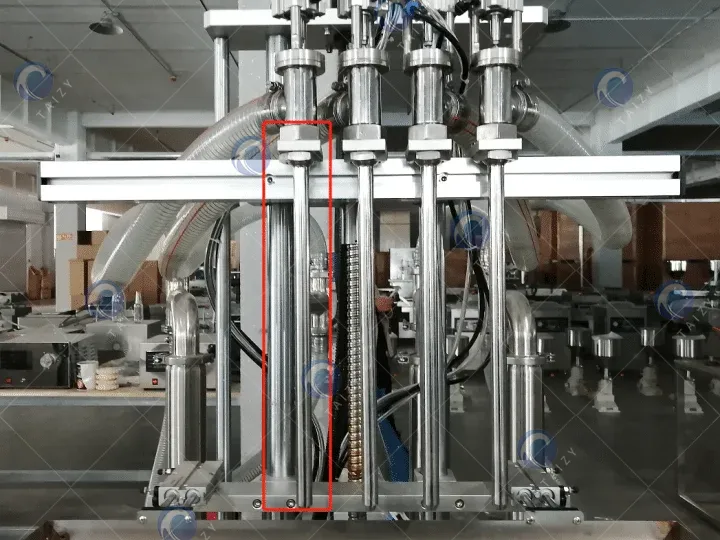

2. فوهات التعبئة: يتوفر طولان. سيكون الطويل أقرب إلى قاع الزجاجة من القصير عند التعبئة. يمكن أن يتجنب الرغوة وصعوبة الختم بفعالية.

3. الخلاط متاح دائمًا لتعبئة الزجاجات أو العلب بالمعجون (لا يتطلب تعبئة السوائل فقط هذا الجهاز). يمكن تجهيزه بـ:

- وظيفة التسخين هذه لمنع التصلب.

- يُستخدم عمود التحريك لمنع التعبئة غير المتساوية للسوائل التي تحتوي على جزيئات.

- عوامة مستوى سائل لاستشعار كمية المواد المتبقية في الخزان تلقائيًا.

4. صمام التحكم في التدفق: يتحكم في الأسطوانة لضبط حجم التعبئة لكل زجاجة.

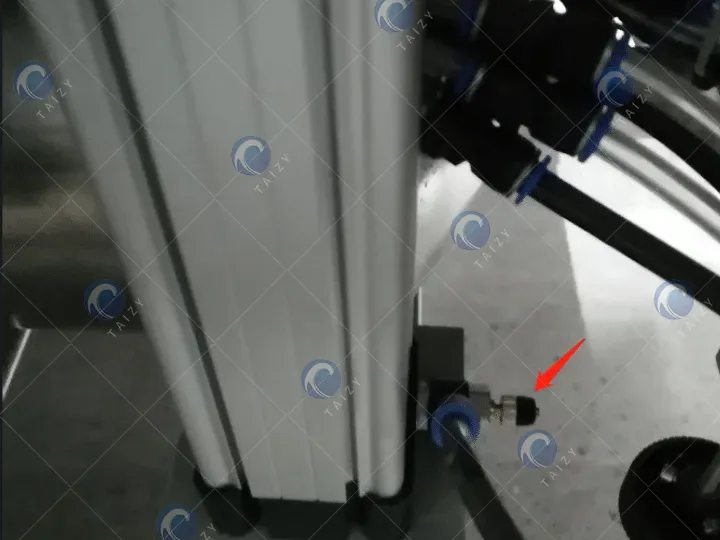

5. صمام التحكم في الضغط: يضبط معدل التدفق لتنظيم سرعة العلب.

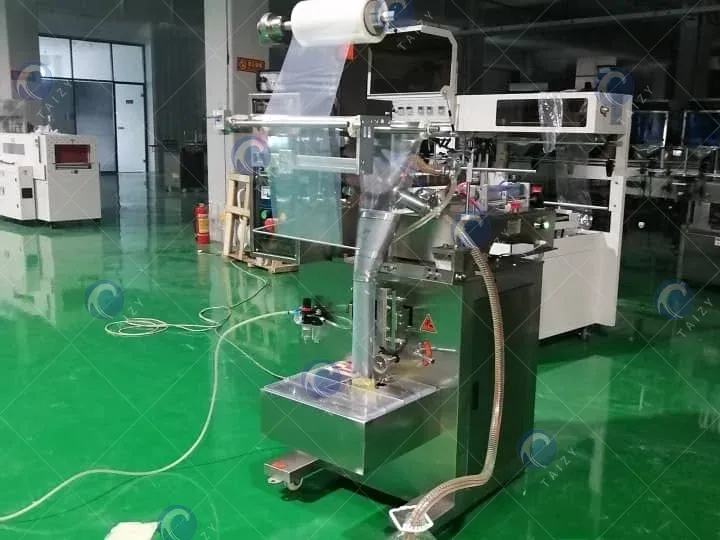

خط إنتاج العصير الأوتوماتيكي بالكامل والمُحسَّن

لتلبية احتياجات معالجة المنتجات عالية الجودة والأوتوماتيكية بالكامل، نوفر أيضًا خط إنتاج تعبئة.

تشمل فارز أغطية بالرافعة، وآلة تعبئة زجاجات سائلة، وآلة تغطية أوتوماتيكية، وناقل أوتوماتيكي، وآلة لصق أوتوماتيكية، وآلة ترميز التاريخ.

1. فارز أغطية بالرافعة

يستخدم في المعدات الداعمة لخط التعبئة، وتتمثل وظيفته الرئيسية في فرز ووضع الأغطية تلقائيًا.

| مزود الطاقة | تيار متردد 220 فولت / 50 هرتز |

| قطر الغطاء المناسب | 30–60 ملم |

| ضغط الهواء العامل | 0.5–0.8 ميجا باسكال |

| وزن | 85 كجم |

| القدرة الإنتاجية | 25–65 قطعة/دقيقة |

| الحجم | 800 × 800 × 2100 ملم |

2. آلة تعبئة سوائل أوتوماتيكية بـ 6 رؤوس

تعتمد طريقة التعبئة على مبدأ الشفط الذاتي للمكبس ويمكن استخدامها على نطاق واسع في خطوط إنتاج التعبئة الأوتوماتيكية للعصائر/المشروبات.

| نطاق التعبئة | 100–500 مل |

| سرعة التعبئة | 1300–1500 زجاجة/ساعة (حسب 500 مل/زجاجة) |

| دقة التعبئة | ±1 جرام |

| الجهد المقنن | 3 مراحل 380 فولت |

| الطاقة المقننة | 3.2 كيلو واط |

| ضغط الهواء العامل | 0.6–0.8 ميجا باسكال |

| وزن | 800 كجم |

| قدرة هوبر | 45–70 كجم |

| الحجم | 1800 × 950 × 2150 ملم |

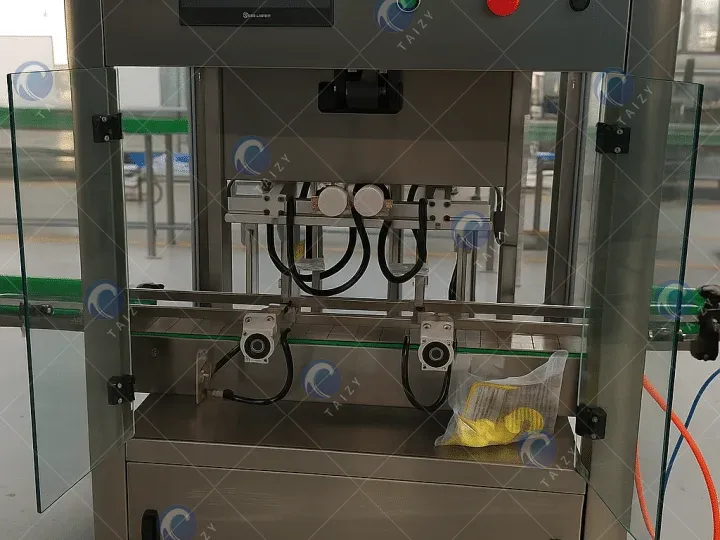

3. آلة تغطية أوتوماتيكية

إنها متوافقة مع مجموعة متنوعة من أنواع الزجاجات، لذلك لا حاجة لاستبدال الملحقات عند تغيير أنواع الزجاجات. هذه الميزة المتمثلة في سرعة الإغلاق السريعة والتكلفة المنخفضة تلبي معظم احتياجات الإنتاج المؤتمت للمؤسسة.

| مزود الطاقة | تيار متردد 220 فولت / 50 هرتز |

| ارتفاع إغلاق الزجاجة | 80–150 ملم |

| قطر الغطاء المناسب | 50–70 ملم |

| قطر الزجاجة المناسب | 50–80 ملم |

| ضغط الهواء العامل | 0.5–0.8 ميجا باسكال |

| وزن | 350 كجم |

| القدرة الإنتاجية | 30–45 زجاجة/دقيقة |

| الحجم | 800 × 900 × 1900 ملم |

| ارتفاع الناقل | 800 ± 50 مم (قابلة للتعديل وفقًا لخط إنتاج العميل) |

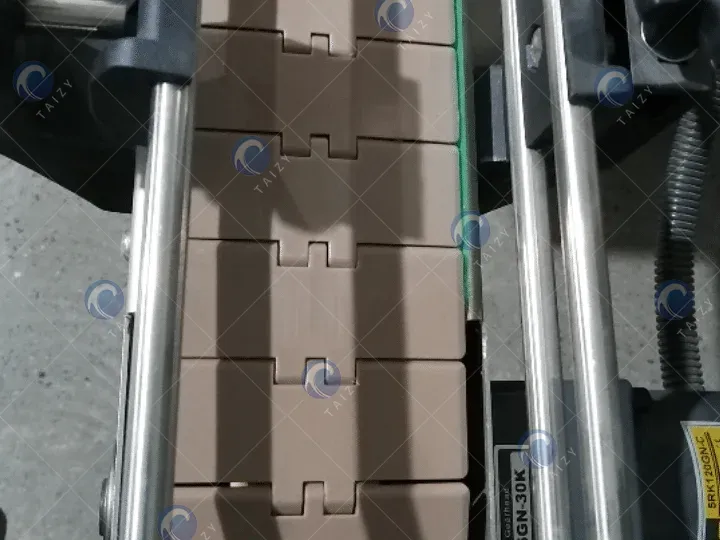

4. ناقل أوتوماتيكي

سلسلة الناقل مصنوعة من حزام سلسلة POM. تقلل بشكل فعال من كثافة العمالة في المناولة اليدوية وتحقق أتمتة الإنتاج.

| عرض حزام الناقل | 82.6 ملم |

| سرعة الناقل | 2–6 م/ث |

| الجهد المقنن | 3 مراحل 380 فولت |

| نظام التحكم في السرعة | تحويل التردد (التحكم في السرعة المتغيرة) |

| وزن الآلة | 210 كجم |

| الارتفاع عن الأرض | 850 مم ± 50 مم (قابلة للتخصيص حسب متطلبات العميل) |

| مادة حزام السلسلة | ستانلس ستيل SUS304 |

5. آلة لصق أوتوماتيكية

يمكن تعديل موضع الملصق وقضيب الإيقاف وفقًا لحجم الكائن المراد لصقه، بحيث يمكن لصق منتجات متعددة بنفس الآلة.

| سرعة اللصق | 25–65 زجاجة/دقيقة |

| دقة اللصق | ±1.5 ملم |

| سرعة تغذية الملصقات | 3–50 م/دقيقة |

| سرعة الناقل | 5–30 م/دقيقة |

| الحجم | 2400 × 1400 × 1780 ملم |

| الملصقات المناسبة | ملصقات لف ذاتية اللصق أحادية الصف (شفافة/غير شفافة)؛ ورق زجاجي شبه شفاف؛ (القطر الداخلي لفة الملصقات: 76.2 ملم؛ أقصى قطر خارجي: 340 ملم؛ عرض ورق الزجاج: 16–200 ملم) |

| وزن | 260 كجم |

| مزود الطاقة | تيار متردد 220 فولت ±5%، 50/60 هرتز |

| إمداد الهواء | 0.4–0.7 ميجا باسكال |

| درجة حرارة التشغيل | 0–50 درجة مئوية |

| رطوبة التشغيل | 15–90% رطوبة نسبية |

6. آلة ترميز التاريخ

يمكنها طباعة تاريخ/وقت الإنتاج، تاريخ انتهاء الصلاحية، رقم الدفعة، الرسومات، الشعار، وتنسيقات أخرى.

| ارتفاع الطباعة | قابل للتعديل 1–15 ملم |

| خطوط الطباعة | 1–4 خطوط، قابلة للتعديل |

| خيارات الخط | 5×8، 8×8، 12×8، 16×16، 24×24 (قابل للتخصيص حسب الطلب) |

| سرعة الطباعة | تصل إلى 128 م/دقيقة (سرعة عالية لخط واحد) |

| توسيع عرض الحرف | تصل إلى 9× تكبير |

| حجم رأس الطباعة | 180 × 43 × 44 ملم |

| مزود الطاقة | 110–240 فولت، 50/60 هرتز |

| درجة حرارة التشغيل | 5–45 درجة مئوية (35–100 فهرنهايت) |

| رطوبة التشغيل | ≤90% رطوبة نسبية، غير متكثفة |

| حجم الآلة | 555 × 300 × 320 ملم |

إذا كنت ترغب في معرفة المزيد عن خط الإنتاج هذا، أرسل لي رسالة. سأجيب على سؤالك في أقرب وقت ممكن.

بالإضافة إلى هذا النوع من آلات تعبئة الزجاجات السائلة، نوفر أيضًا آلات تعبئة شبه أوتوماتيكية وآلات تعبئة دوارة، وهي مناسبة أيضًا لتعبئة المواد السائلة.

إذا كنت ترغب في الحصول على مزيد من التفاصيل حول معلومات أخرى، اتصل بي أو أرسل بريدًا إلكترونيًا، وسأرد في أقرب وقت ممكن.