Sambal chili sauce is an integral part of Singapore’s culinary culture, particularly in takeout and ready-to-eat meals. However, many small food processing plants face the challenge of improving production efficiency within limited space and strict regulations.

Here is an interesting case from one of our customers, who owns a small sauce factory and is ready to order a hot sauce packaging machine to solve such problems.

Customer’s background and the problems she encountered

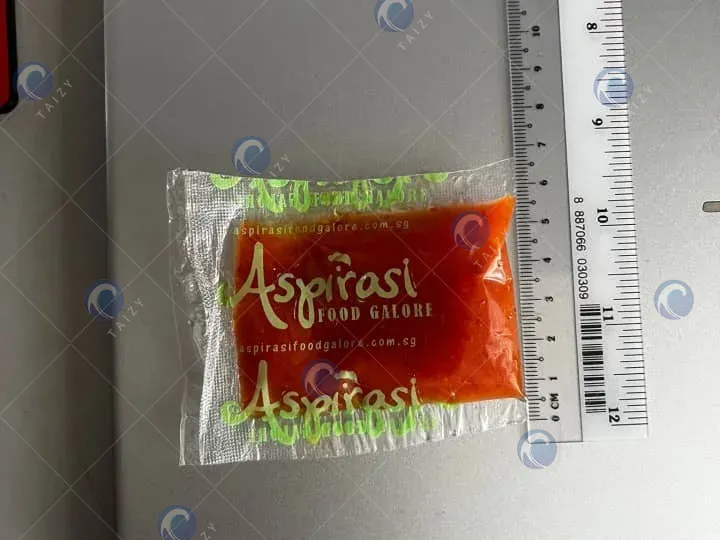

Our client is a small condiment manufacturer located in Singapore’s Food Park. She specializes in producing sambal chili sauce, which she supplies to local restaurant chains and e-commerce platforms. Her small factory produces thousands of individual 21-24g sachets daily, primarily for takeout and pre-packaged food.

Previously, most of their machines were semi-automatic. As the number of orders increased, she had some pressure on production.

“I have long wanted to buy a set of fully automated machines. My equipment is too old. Today’s food supervision is very strict. Only by updating the equipment can I stabilize my business.” She shares her feelings and puts forward some requirements for the machine:

- Since sambal chili sauce contains particles that are easy to sink and solidify, she needs a stirring function on this hot sauce packaging machine.

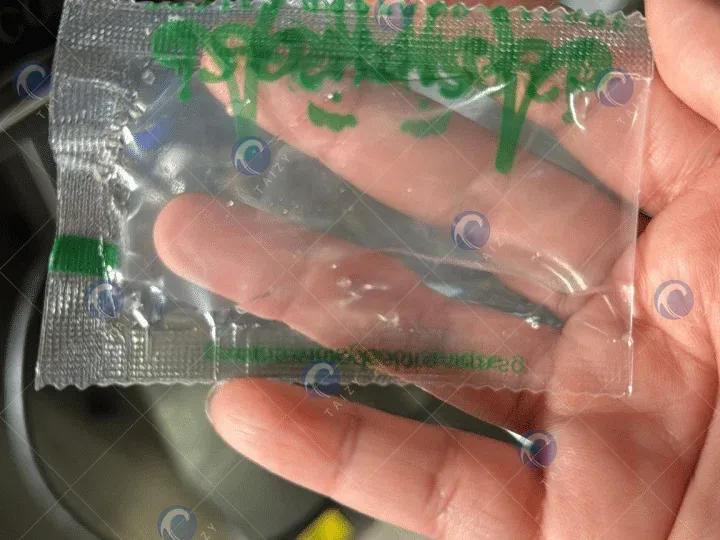

- Her packaging bag requires three sides with serrated edges, and it needs to have a beautiful appearance and sturdy construction with an easy-opening mechanism.

- The machine needs to be small, as her factory has limited space.

- It should be easy to clean and meet food safety standards. The pasta packaging machine manufacturer needs to provide cleaning and maintenance videos about this machine.

Customer needs analysis and our solutions

After several rounds of communication, we recommended a small fully automatic chili sauce packaging machine with the following features that perfectly met her requirements:

- Equipped with a stirring system to prevent sambal chili sauce from segregating and ensure even distribution of ingredients during filling.

- A precision filling pump ensures a consistent weight of 21-24g per package, reducing waste.

- The heat sealer and cutter part provides a secure seal, preventing sauce leakage and enhancing the packaging’s aesthetics.

- Constructed of stainless steel, it meets SFA(Singapore Food Agency) hygiene standards and is easily disassembled and cleaned for daily cleaning.

The size of this machine is 1150*700*1750mm with a capacity of 24-60 bags/min. Our client is satisfied and quickly determines the machine drafting contract. Here is its simple structure for showing the significant advantages of this paste packaging machine.

Hot sauce packaging machine brings significant results

After receiving the machine, our customer lamented that she finally felt relieved. She replied, “I received the machine. The packaging speed and quality are very good. Our production pressure is now greatly reduced.”

“The product has also successfully passed the SFA annual food safety inspection, and our sales channels have been expanded!” Not long after, she brought this good news.

As competition in Singapore’s food industry intensifies, automated packaging equipment has become crucial for increasing production capacity, reducing costs, and ensuring regulatory compliance.

This case demonstrates how small and medium-sized food processing plants can achieve efficient production, food safety, and brand enhancement within limited space through Taizy packaging solutions.

If you’re also looking for an automated hot sauce packaging machine, please contact us for more localized case studies and solutions.