作为一种收缩包装设备,流包装机专为生产食品和轻工业中的日常必需品如面包、巧克力和肥皂而设计。它可以每分钟包装25-230袋。

凭借在全球范围内的良好声誉,Taizy提供先进的专业流包装机,操作简单但有效,设置快速可调,以及出色的准确性和精度。

流包装机的优点

高精度不粘保证

得益于我们设备的高精度定位和跟踪能力、锋利的刀片和先进的光电传感器,层压和切割过程保持干净且不粘,确保包装的完整性和整洁。

人性化设计,国际化标准

我们的面包包装机采用世界知名的电气组件,并结合智能PLC和触摸屏系统。它还提供方便的参数设置、快速故障检测以及易于操作和升级,确保操作简便和用户友好。

电机控制及完整流程

该流包装机的包装速度和长度由伺服电机精确控制,实现无限可调速度以满足多样化的包装需求。

温度控制和密封

配备独立的比例积分微分(PID)技术,根据原材料的熔点调整密封温度,以达到最佳密封效果并确保包装外观良好。

流包装机的参数

饼干包装机有两种膜进料方式:

一种是上进料包装机,适用于材料或表面较硬的物品(如糖果、饼干、肥皂、棉签)。与这种类型相比,下进料包装机适用于材料较软的物品(例如,毛巾、衣物、口罩)。

Taizy流包装机有三种型号,详细技术参数如下:

| 类型 | TZ-350 | TZ-450 | TZ-600 |

| 胶卷宽度 | 不超过350mm | 不超过450mm | 不超过600mm |

| 袋长 | 65-190mm/120-280mm | 100-600mm | 130-540mm |

| 袋宽 | 50-160mm | 50-210mm | 70-280mm |

| 产品高度 | 不超过60mm | 100mm | 不超过110mm |

| 膜卷直径 | 不超过320mm | 不超过320mm | 不超过320mm |

| 包装速率 | 25-120袋/分钟 | 30-80 袋/分钟 | 20-80 袋/分 |

| 包装材料 | OPP,OPP/CPP,KOP/CPP,铝膜 | OPP,OPP/CPP,KOP/CPP,铝膜 | OPP,OPP/CPP,KOP/CPP,铝膜 |

| 力量 | 220V,50/60Hz,2.6KW | 220V,50Hz,2.6KW | 220V,50/60Hz,3.6KW |

| 机器尺寸 | 4020*820*1450mm | 4020*720*1450mm | 4030*900*1650mm |

注意: 膜宽=(宽度+高度)×2+2cm

此外,机器还可以配备充气(空气或氮气)和编码设备,用于填充和编码。如果您想询问定制其他配件的可能性,请随时给我发消息。

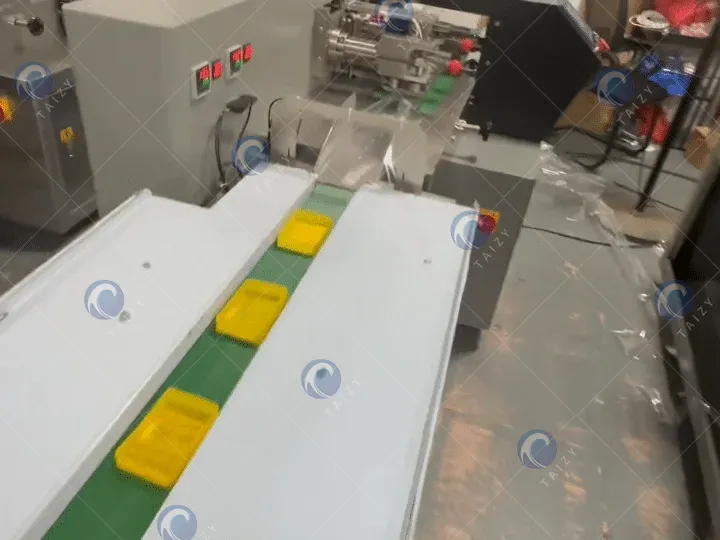

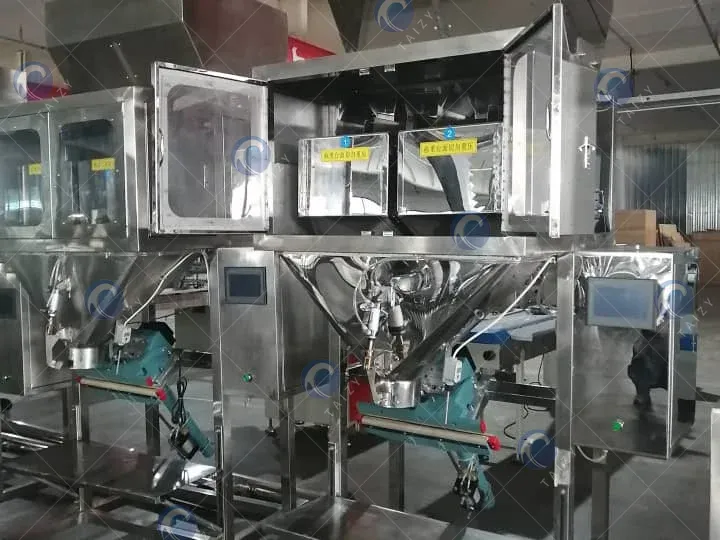

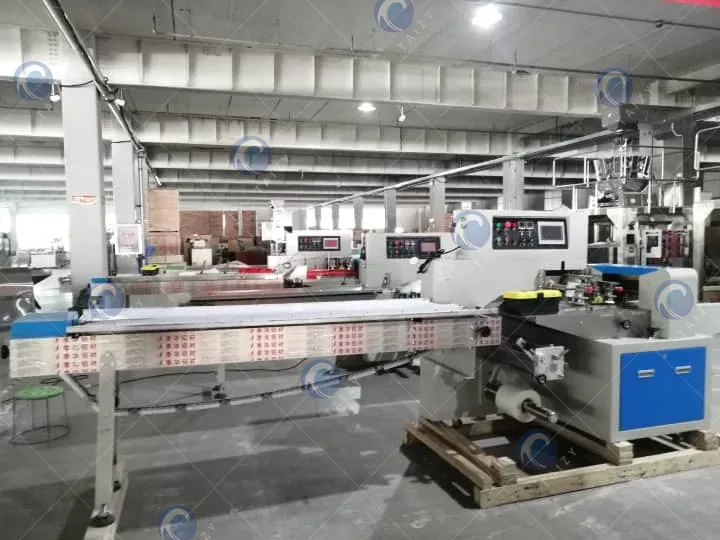

作为源头制造商,我们更加关注机器的质量。以下是我们工厂的一些图片。如果您想检查机器的质量,请随时访问我们的工厂。如果您有任何问题,请与我联系

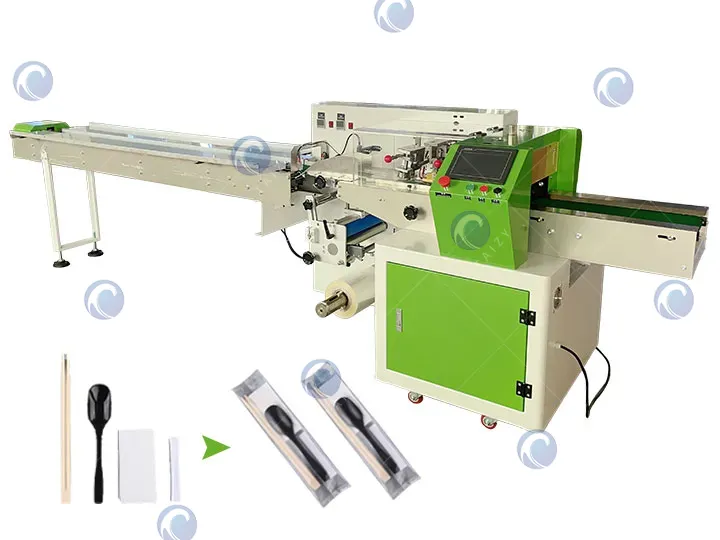

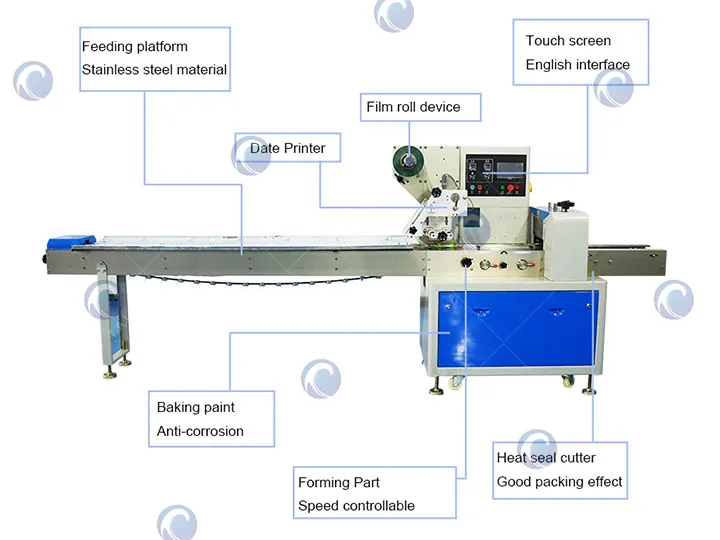

枕式包装机的结构

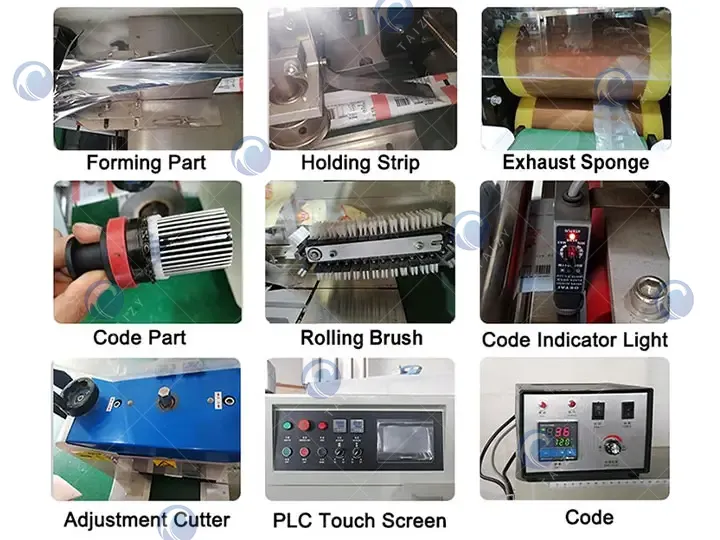

我们的包装机集机头、机身、进料平台、日期打印机、卷膜装置、产品推送器、触摸屏、输出输送机、端封装置于一体。

一些部件可以根据您的真实需求进行定制:

- 有两种类型 输送带 可选择:带式和按扣式。您可以根据不同材料选择。(如果不知道如何选择,欢迎随时咨询我们!)

- 这种封口包装机分为 顶部薄膜送料和底部薄膜送料 类型。根据物体的硬度,您可以决定类型。

- 海绵和刷子 配件可用于促进包装和空气排出。

此外,如有需要,我们将为您配备一个滚刷,其主要功能是压平和紧凑包装膜的表面,保持其平整,并在整个过程中通过输送带不断向前运输,以形成完整的装配线。

流包装机的应用

这种自动打包机可用于包装固体食品,如蛋糕、派、焦糖点心、巧克力、糖果、面包、方便面、饼干和药丸,以及其他日常必需品,如毛巾、肥皂、口罩和衣物。

它还可以用于玩具和文具、塑料产品、工业用品、一次性产品、五金、工业零件,甚至汽车零件。

糖果流包装机的工作原理

包装部分工作进度:

- 将塑料袋折叠在一起

- 加热袋

- 将袋子密封在一起

切割部分工作进度:

在袋子通过夹具后,旋转刀辊将自动切断它们。

简要流包装机的工作流程

进行安全检查 → 打开总电源开关和加热器开关 → 设置袋长 → 安装包装膜 → 调整色标 → 调整料位 → 试运行 → 正常生产

常见错误更正 面包包装机

膜偏差

如果薄膜偏离正常位置,调整薄膜轮并抬起制袋器,使挡块刚好推动,不接触薄膜。如果无效,进纸编码器或组件可能无法工作。这就需要立即更换相应的部件。选择合适的替换件后,需要改变胶片的宽度来调整手轮,从而使宽度合适。

内容被切割机切割

如果膜中包含的物品被刀或切割机切割,您需要调整这些材料的位置,然后调整对产品的压紧弹簧片的压缩程度。之后,您还需要调整水平密封的高度,以确保切割机的接合面位于产品水平的中间位置。

未能对齐颜色标记

首先,重新设定长度,清理滚筒上的污垢和黑点。其次,调整高光电眼与胶片的距离或高光电眼上的灵敏度旋钮。第三,调整制动手上的夹块与弹簧连接的角度,将补偿值设置为38左右。

详细操作步骤及熟悉方法请参阅产品说明书。如有任何其他问题,请随时留言。我们将尽快与您联系。

除了这款流包装机外,我们还提供其他类型的设备。

如果您想包装液体,糊状包装机是更好的选择。液体袋装填充机将帮助包装水、牛奶等产品。如果您有任何疑问,请告诉我。点击联系,询问详细价格和信息!