该液体灌装机每小时可灌装500-2000瓶500毫升的物料,效率很高。它计算精确,100毫升以上灌装误差小于1%。其灌装范围为500至2000毫升,可满足大多数工业饮料灌装需求。

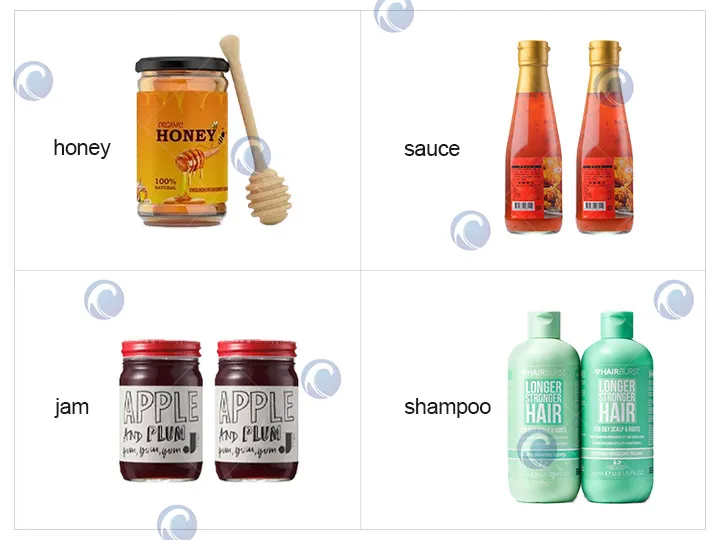

与此同时,Taizy 液体瓶装填充机广泛应用于食品、医药、化工、日化、石油、兽药、农药等各个行业的液体、粘稠液体、膏体和酱料的填充。

为什么众多食品加工商选择我们的液体灌装机?

我们的大多数客户将液体和膏体灌装机纳入食品或其他类型的生产线。但他们为什么选择这种设备?原因如下:

- 整机采用SUS304材质,符合GMP标准。它为食品生产创造了无菌环境,并确保了产品质量。

- 该液体灌装机采用进口伺服电机驱动活塞缸,实现计量灌装,灌装量精确,并具有计数功能。

- 如果需要更改规格或调整灌装量,可以直接在触摸屏上操作,简单方便。机器还附带了教学视频和机器手册,让您轻松上手。

- 配备日本松下光电系统,可精确识别灌装瓶的定位状态,识别到瓶子才会工作。

不同类型的液体灌装机及其技术参数

灌装机分为两种:液体灌装机和膏体灌装机。膏体灌装机比液体灌装机多一个搅拌器。您可以为您的物料选择特定的灌装机。

以下是它们不同容量的一些参数。

| 类型 | AT-SFGZ-L4 | AT-SFGZ-L6 | AT-SFGZ-L8 | AT-SFGZ-L12 | AT-SFGZ-L16 |

| 灌装喷嘴 | 4 | 6 | 8 | 12 | 16 |

| 测量范围 | 500-2000毫升 | 500-2000毫升 | 500-2000毫升 | 500-2000毫升 | 500-2000毫升 |

| 灌装精度 | ±1%(100毫升) | ±1%(100毫升) | ±1%(100毫升) | ±1%(100毫升) | ±1%(100毫升) |

| 生产能力(以500毫升为基准) | 500-1000 瓶/小时 | 800-1600 瓶/小时 | 1000-2000 瓶/小时 | 1500-3000 瓶/小时 | 2000-4000 瓶/小时 |

| 气源压力 | 0.5-0.7兆帕 | 0.5-0.7兆帕 | 0.5-0.7兆帕 | 0.5-0.7兆帕 | 0.5-0.7兆帕 |

| 耗气量 | 20升/小时 | 30升/小时 | 40升/小时 | 60升/小时 | 100升/小时 |

| 总功率 | 2.0千瓦 | 2.0千瓦 | 2.0千瓦 | 2.0千瓦 | 2.0千瓦 |

| 重量 | 300 千克 | 400千克 | 500千克 | 700千克 | 900千克 |

| 整体尺寸 | 400*110*210厘米 | 400*110*230厘米 | 400*115*230厘米 | 600*100*230厘米 | 600*100*230厘米 |

该液体灌装机的应用范围

如果您想了解其应用范围,需要满足两个条件:

- 容器可以是瓶子、罐子或桶。

- 物料是流动的液体或膏体。

所以,满足这两个原则后,您就可以选择合适的机器了。

液体瓶装填充机的应用范围:

- 食品工业:水、果汁、油、醋、乳制品等。

- 制药行业:瓶装液体药物、糖浆、口服溶液等。

- 日化行业:瓶装液体洗涤剂、洗发水、护发素、乳液、液体香皂、消毒剂等。

膏体瓶装填充机的应用范围:

- 食品工业: 花生酱、果酱、蜂蜜、番茄酱、辣椒酱、芝麻酱等。

- 制药行业:软膏、凝胶、奶油、草药提取物等。

- 日化行业:面霜、身体乳、护发素、牙膏、手部消毒凝胶等。

液体瓶装填充机的详细组件

1. 产品进料输送带:默认宽度为101毫米,可定制。

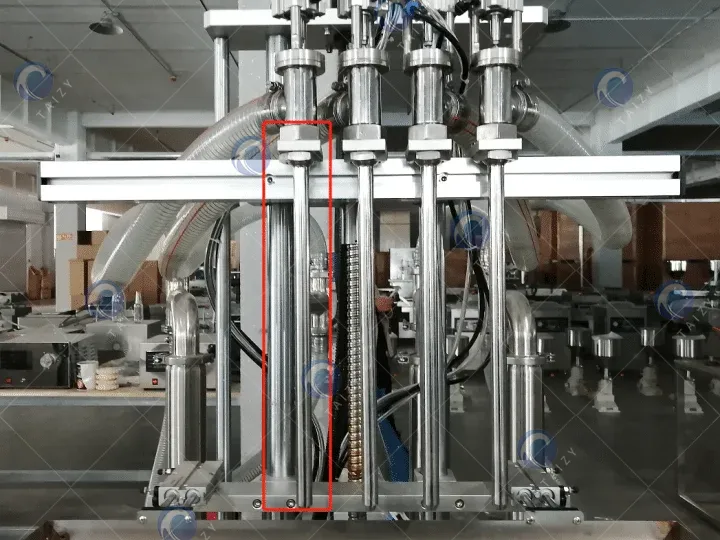

2. 灌装喷嘴:提供两种长度。较长的喷嘴在灌装时比较短的喷嘴更靠近瓶底。它可以有效地避免泡沫和密封困难。

3. 搅拌机通常适用于膏体瓶或罐的填充(仅液体填充不需要该设备)。可以配备:

- 此加热功能用于防止凝固。

- 搅拌轴用于防止含有颗粒的液体填充不均匀。

- 液位浮子,用于自动感应罐内剩余物料量。

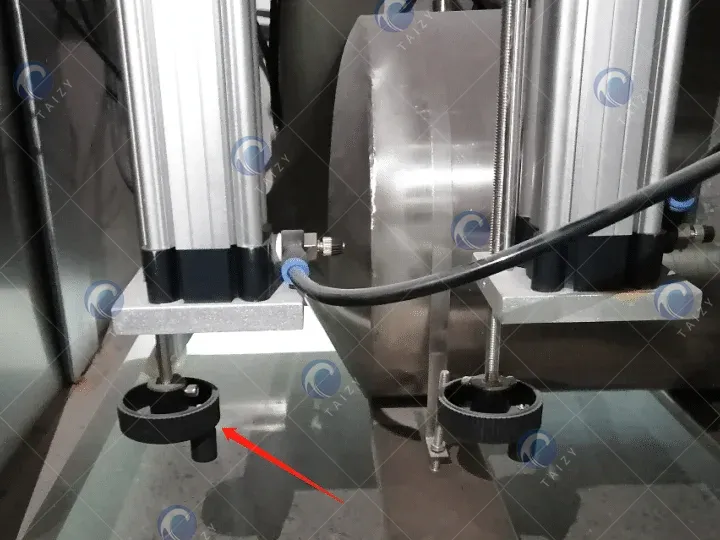

4.流量控制阀:它控制气缸以调整每个瓶子的灌装量。

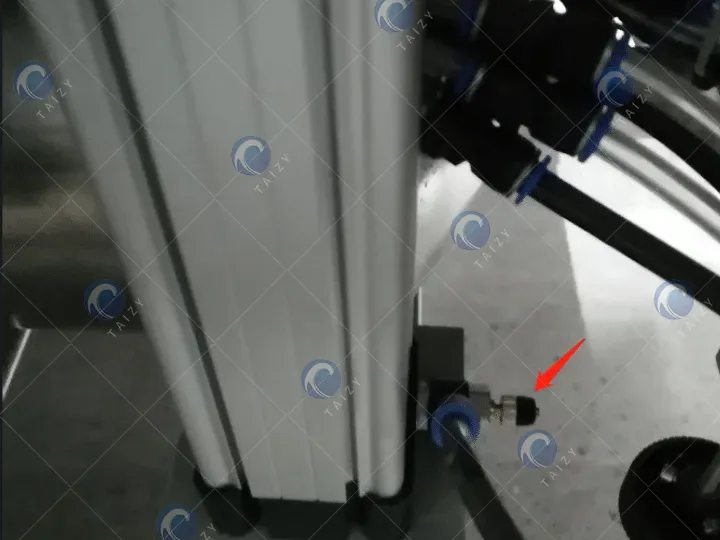

5. 压力控制阀:调节流量以控制灌装速度。

升级版全自动果汁生产线

为了满足高质量、全自动的产品加工需求,我们还提供灌装生产线。

它包括一个电梯帽分拣机、一个液体瓶装填充机、一个自动封口机、一个自动输送带、一个自动贴标机和一个日期编码机。

1. 电梯帽分拣机

用于填充线的配套设备,其主要功能是自动分拣和放置瓶盖。

| 电源 | AC 220 V/50 Hz |

| 适用瓶盖直径 | 30–60 mm |

| 工作气压 | 0.5–0.8 MPa |

| 重量 | 85 kg |

| 生产能力 | 25–65 pcs/min |

| 尺寸 | 800 × 800 × 2100 mm |

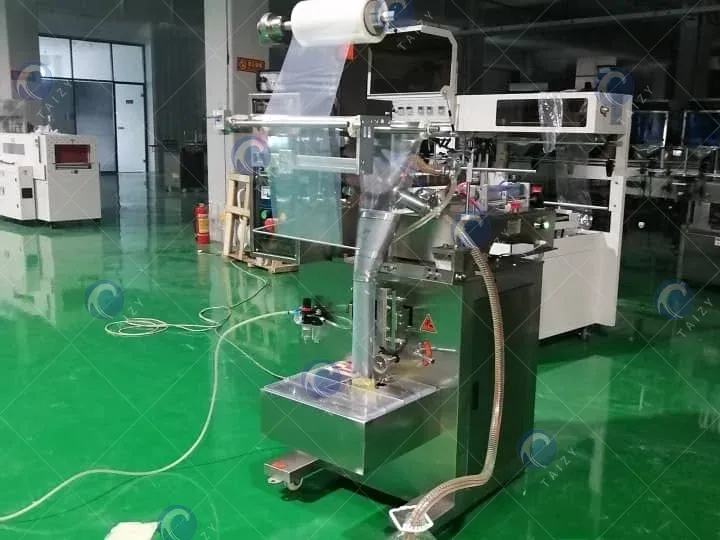

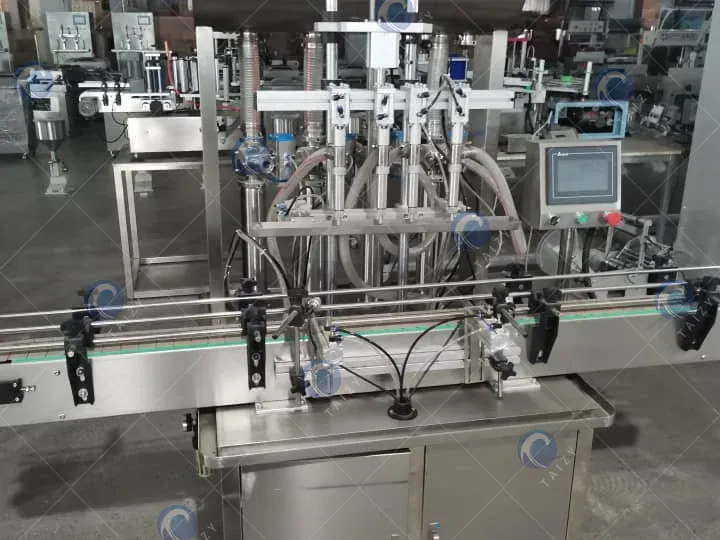

2. 6头全自动液体填充机

填充方式采用活塞自吸原理,可广泛用于果汁/饮料自动包装生产。

| 灌装范围 | 100–500 ml |

| 填充速度 | 1300–1500 瓶/小时(基于 500 ml/瓶) |

| 填充精度 | ±1 g |

| 额定电压 | 三相 380 V |

| 额定功率 | 3.2 kW |

| 工作气压 | 0.6–0.8 MPa |

| 重量 | 800 kg |

| 料斗容量 | 45–70 kg |

| 尺寸 | 1800 × 950 × 2150 mm |

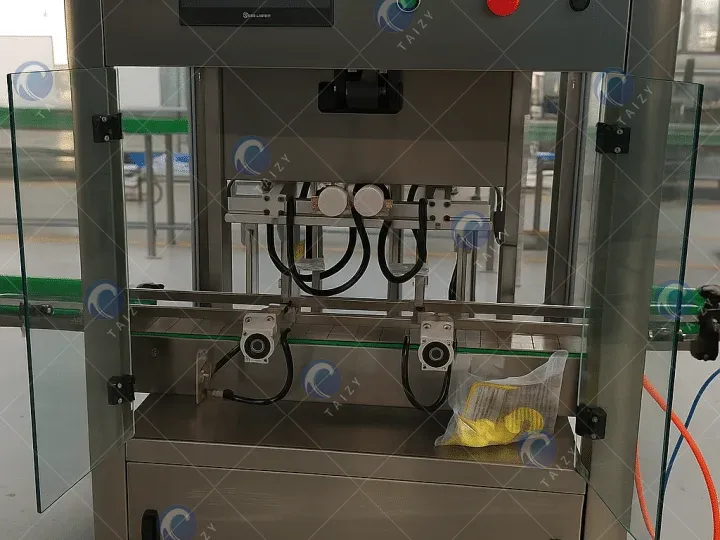

3. 自动封口机

兼容多种瓶型,更换瓶型无需更换配件,封盖速度快、成本低,满足企业大多数自动化生产需求。

| 电源 | AC 220 V/50 Hz |

| 瓶封高度 | 80–150 mm |

| 适用瓶盖直径 | 50–70 mm |

| 适用瓶直径 | 50–80 mm |

| 工作气压 | 0.5–0.8 MPa |

| 重量 | 350 kg |

| 生产能力 | 30–45 瓶/分钟 |

| 尺寸 | 800 × 900 × 1900 mm |

| 输送带高度 | 800 ± 50 mm(可根据客户生产线进行调整) |

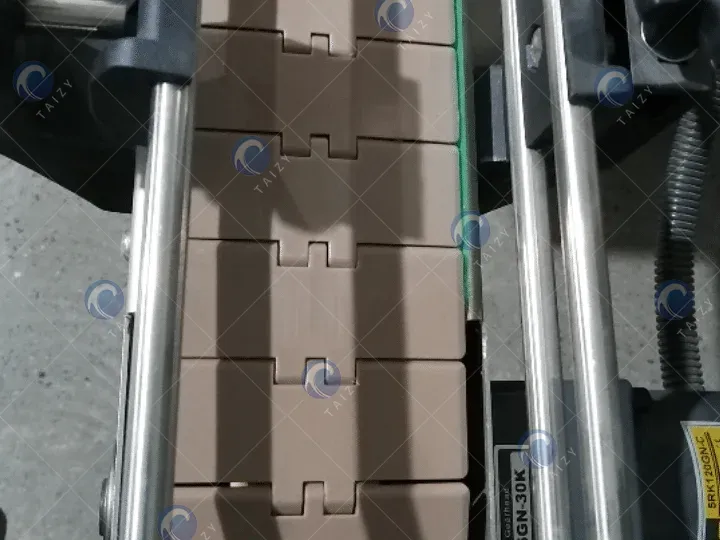

4. 自动输送带

输送链由 POM 链带制成。有效减少了人工搬运的劳动强度,实现了生产的自动化。

| 输送带宽度 | 82.6 mm |

| 输送速度 | 2–6 m/s |

| 额定电压 | 三相 380 V |

| 速度控制系统 | 频率转换(变速控制) |

| 机器重量 | 210 kg |

| 离地高度 | 850 mm ± 50 mm(可根据客户要求定制) |

| 链带材料 | SUS304 不锈钢 |

5. 自动贴标机

贴标位置和停止杆可以根据待贴标物体的大小进行调整,从而使多个产品可以用同一台机器贴标。

| 贴标速度 | 25–65 瓶/分钟 |

| 贴标精度 | ±1.5 mm |

| 标签进给速度 | 3–50 m/min |

| 输送速度 | 5–30 m/min |

| 尺寸 | 2400 × 1400 × 1780 mm |

| 适用标签 | 自粘单行卷标(透明/不透明);半透明玻璃纸底纸; (标签卷内径:φ76.2 mm;最大外径:φ340 mm;底纸宽度:16–200 mm) |

| 重量 | 260 kg |

| 电源 | AC 220V ±5%,50/60 Hz |

| 气源供应 | 0.4–0.7 MPa |

| 工作温度 | 0–50 ℃ |

| 工作湿度 | 15–90% RH |

6. 日期编码机

可以打印生产日期/时间、过期日期、批号、图形、LOGO 和其他格式。

| 打印高度 | 可调 1–15 mm |

| 打印行数 | 1–4 行,可调 |

| 字体选项 | 5×8, 8×8, 12×8, 16×16, 24×24 (可根据要求定制) |

| 打印速度 | 最高可达 128 m/min(单行高速) |

| 字符宽度扩展 | 最高可达 9× 放大 |

| 打印头尺寸 | 180 × 43 × 44 mm |

| 电源 | 110–240 V, 50/60 Hz |

| 工作温度 | 5–45 ℃ (35–100 ℉) |

| 工作湿度 | ≤90% RH,无冷凝 |

| 机器尺寸 | 555 × 300 × 320 mm |

如果您想了解更多关于这条生产线的信息,请给我留言。我会尽快回复您的问题。

除了这种液体灌装机,我们还提供半自动灌装机和旋转式灌装机,它们也适用于液体物料的灌装。

如果您想了解更多其他信息,请致电或发送电子邮件给我,我会尽快回复。