Taizy launches popcorn packaging machine for spherical snack packaging, which has a wide range of applications, including popcorn, melon seeds, peanuts, and broad beans. We provide various sealing styles such as back seal, three-side seal, four-side seal, etc.

Our machine supports packaging widths of 20-200mm, packaging lengths of 30-180mm, and weights of 100-1000g. Its packaging speed can reach 20-100 bags/min. As a high-quality packaging machine, it has been exported to the USA, Canada, the Netherlands, Malaysia, the United Arab Emirates, and Brazil etc.

Highlights of the popcorn packaging machine

- The entire machine is made of 304 stainless steel and also has international CE or other export certifications. The high-quality material ensures food safety and durability.

- This popcorn packaging machine is equipped with an intelligent PLC control screen, which can set bag length, cutter temperature, packaging speed, and material bag length. Besides, it also has counting and cursor-sensing functions.

- The specially assembled turntable has a weighing function, which can accurately control the weight of the package.

- In addition, we also provide other customized services: date printer, exhaust or inflation device. If you have any requirements, you can also consult us.

Structure of popcorn packaging equipment

Our popcorn packaging machine is mainly composed of a hopper, a turntable, a former, two motors, and cutters.

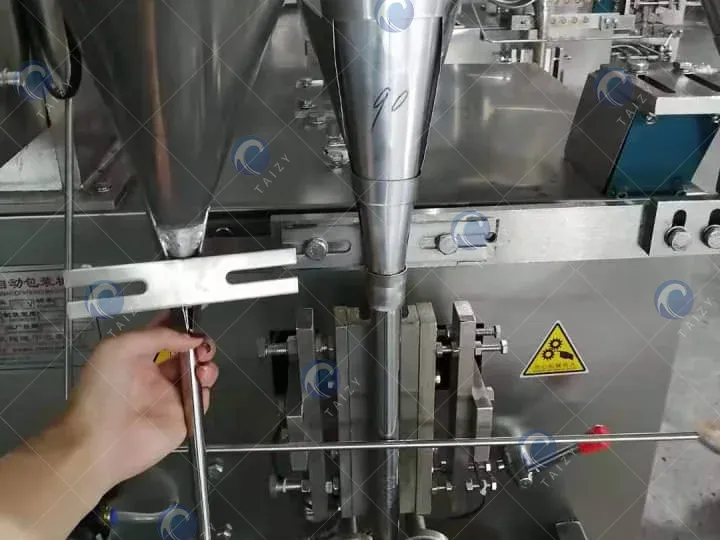

1. Hopper

This hopper has a large conical structure that can accommodate more raw materials. What’s more, the large opening is convenient for workers to add materials or convenient for connect with the elevator in a production line.

2. Turntable feeding

There is a special design that is different from other types of granular packaging machines. This machine has a different feeding way-a turntable with four measuring cups.

Unlike other manufacturers on the market, our barrel positioning ring is made from 5mm 304 stainless steel, which significantly increases the machine’s load-bearing capacity. It enables it to handle large-scale continuous packaging.

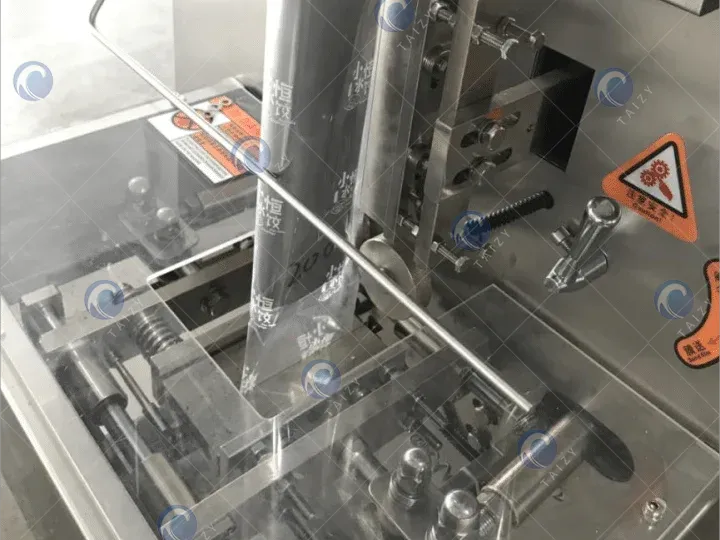

3. Former

The function of the former is to fold the roll of film into a cylindrical bag accurately. If you want to change the width of the bags, you just need to replace the old former.

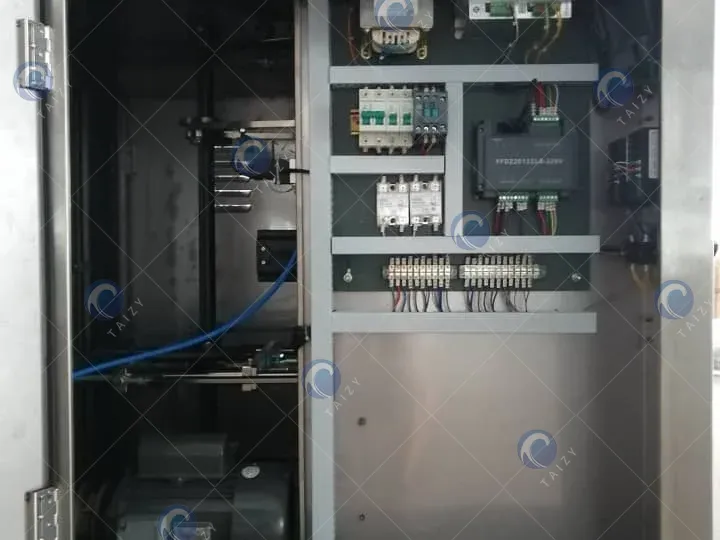

4. Motor

The entire popcorn packaging machine has two motors: the main motor and the film pulling motor.

The main motor is responsible for the machine’s sealing, cutting, and overall synchronization, ensuring stable operating speed and consistent packaging performance.

The film-pulling motor smoothly pulls the film through the former, which ensures precise film feed, accurate bag length, and consistent seal position, effectively reducing film deviation and waste.

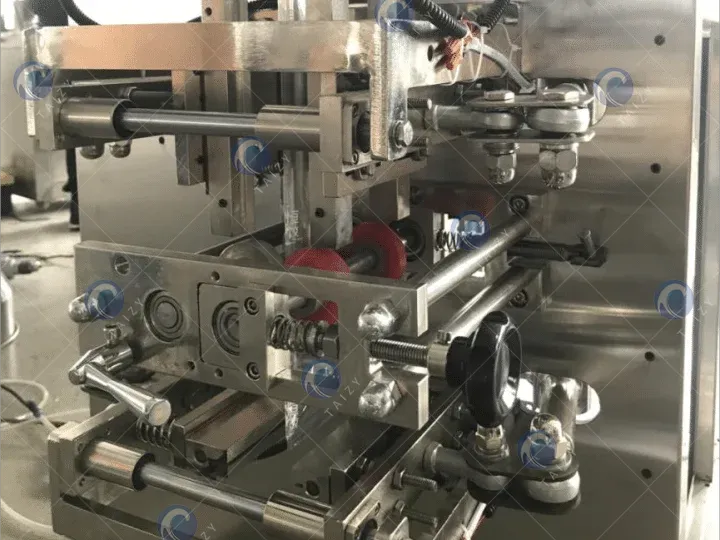

5. Cutter

The cutter determines the sealing method of the package. We provide back seal, three-side seal, and four-side seal packaging methods. If you want gusseted bags or other forms of packaging, please contact our customer service for customized services.

Models and parameters of Taizy snack packaging machine

There are two models of our turntable granule packaging machine: TZ-320 and TZ-450.

| Mfano | TZ-320 | TZ-450 |

| Packing bag style | 4-side seal,3-side seal, back seal | back seal, 3-side seal |

| Packing speed | 20-80mfuko/dakika | 50-100bags/min |

| Power consumption | 1.8kw | 2.2kw |

| Machine weight | 250kg | 420kg |

| Packing weight | 0-200g | 100-1000g |

| Bag width | 20-150mm | 20-200mm |

| Bag length | 30-180mm adjust | 30-180mm adjust |

| Dimensions | 650*1050*1950mm | 750*750*21000mm |

Applications of the quantitative packaging machine

Popcorn packaging machines are highly popular for some food processing plants that use them to package snacks, grains, and nuts for wholesale and retail. Some of our customers also purchase multiple units to put into their food production lines, which greatly improves production efficiency.

Additionally, this machine is also utilized in the agricultural, chemical, and pharmaceutical industries. Due to its excellent properties, stainless steel is not affected by pollution caused by corrosive powder and can effectively protect the factory environment.

What can Taizy bring to you?

- Taizy will provide you with the most suitable customized solution based on your production needs. We can match your needs, whether for small factories or large production lines.

- We have our own factory, not only ensuring a competitive price, but also having strict quality control of our machines.

- We provide one-stop service, including pre-sales consultation, sales follow-up, and after-sales support etc.

- Taizy has been exporting for over a decade and has extensive global experience, exporting to over 100 countries and regions.

If you are looking for a good packaging manufacturer or want to solve your packaging problems. Please contact us!