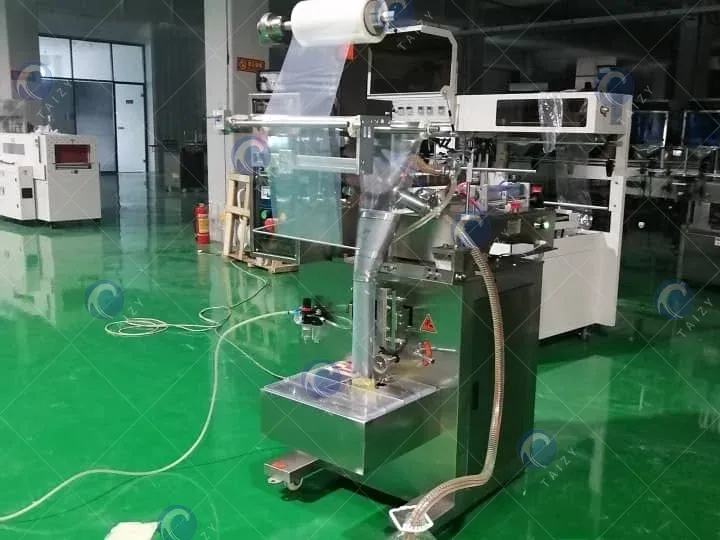

This ice pop packing machine specializes in packaging composite film jelly bars, ice popsicles, and other pure liquid materials with good fluidity. The finished product is packaged in a cylindrical shape, which is easy to carry and is very popular among children and teenagers in China, India, Japan, South Korea, Nigeria, and other regions.

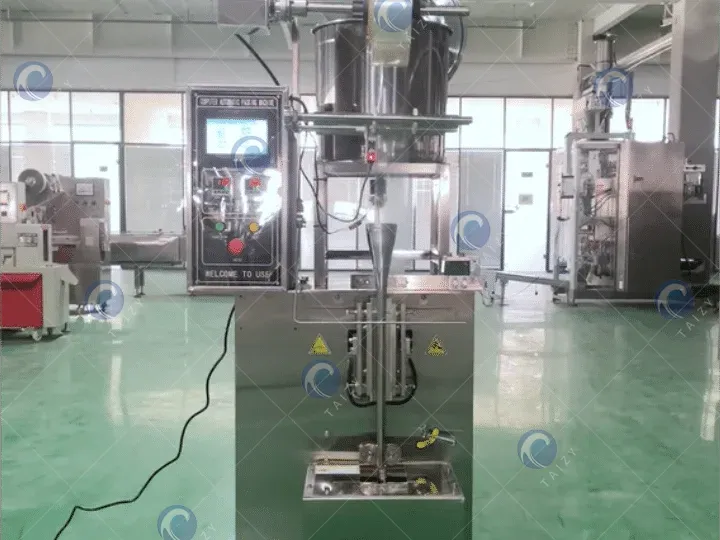

Taizy jelly pouch packing machine delivers a high packing speed of 20–72 bags per minute. Equipped with a gravity feeding system, it accommodates bag length from 30 to 280 mm and width from 25 to 145 mm. All material-contact parts are made of stainless steel for durability and hygiene. If you need to do all stainless steel, we also provide private customization.

この特殊なアイス自動ポップ包装機の特徴

- このアイスキャンディーパッケージングマシンは高度な フォトエレクトリック追跡システムを備えたマイクロコンピュータチップ制御, 各パックの正確なシールとカットを保証します。

- その独特な シーリングシステム 漏れや損傷を防ぎ、外装の美観と品質を確保する安全できちんとしたシールを保証します。

- タイジーアイスキャンディーパッキングマシンは装備されています 自動停止機能. 機械の停止時に、供給システムは自動的に停止し、材料の無駄を防ぎ、きちんとしたシールと清潔な包装を確保します。

- すべて 材料接触部分は耐久性のあるステンレス鋼で作られています, 衛生と食品安全を確保し、外殻には追加の保護のためにコーティングされています。

- The ice pop packing machine is purpose-built for packaging jelly sticks and ice pops, ensuring high-speed operation, accurate sealing, and consistent product quality.

アイスポップ包装機の仕様

| 袋のスタイル | Back sealing |

| 包装速度 | 20–72 bags/min |

| 袋長さ | 30–280 mm |

| 袋幅 | 25–145 mm (requires changing the former) |

| Feeding method | Gravity feeding system |

| 消費電力 | 1.8 kw |

| 機械重量 | 250 kg |

| 寸法 | 650*850*1850 mm |

アイスロリー包装機の構造と動作原理

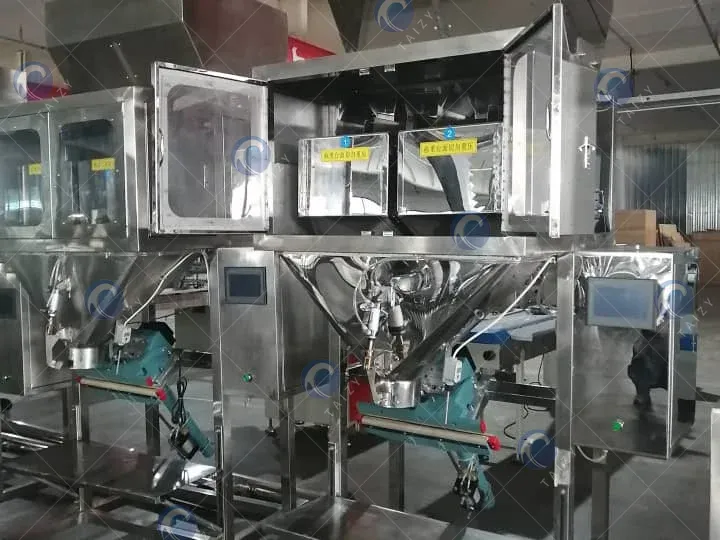

Taizy ice pop packing machine primarily consists of film feeding, forming, filling, sealing, and cutting systems.

- Forming system: The packaging film is automatically unwound and guided through a former to shape it into a tubular bag. The machine employs a back-sealing method to achieve a neat and strong seam.

- Filling system: The liquid material is stored in the hopper, which flows through a filling tube, into the formed tube without leakage or bubbles.

- Sealing system: The machine applies longitudinal heat sealing to create strong seals. Its unique sealing system ensures that the sealed ends are neat and leak-proof.

- Cutting and output system: After sealing, the machine cuts the film into individual bags according to the set length (30–280 mm).

アイスポップ包装機の実際の価格

The real cost of an ice lolly filling and sealing machine depends on multiple factors. But the price of a single machine is just a few thousand dollars.

Factors that affect the overall price include:

- Packaging and shipping charges

- Essential spare parts

- Optional customization

For example, customers can choose to add a date-printing device, upgrade material options such as full stainless steel or partial stainless steel construction, and tailor the machine to meet specific production needs. These elements ensure you receive a fully equipped and reliable solution rather than just a standard unit.

However, although full stainless steel will be more expensive than partial stainless steel, its service life and food safety guarantee will also give you more reliability. You can change the choice based on your real situation.

どの機械を選ぶべきかわからない場合や、完全な価格表を入手したい場合は、ぜひご相談ください。当社のサービス担当者が理想の機械を見つけるお手伝いをします!

Another liquid packing machine is here. Have a look at it to see whether you need this: liquid pouch filling machine.