Taizy chips packaging machine est largement utilisée pour divers types d'aliments soufflés, graines et noix grillées, aliments gélifiés, jouets en plastique, et autres matériaux granulaires ou en bandes. La largeur d'emballage est de 80-200mm, et la longueur d'emballage est de 80-240mm avec divers styles de sachets : sachets à joint 3 côtés, sachets à joint 4 côtés, sachets stand-up, sachets à poignée, etc.

De plus, elle possède une conception verticale, équipée d'une peseuse combinée 10-head, une vitesse d'emballage de 20-80 sacs/min et une variété de matériaux d'emballage. Elle résout parfaitement le problème des chips de pomme de terre fragiles pendant le processus d'emballage.

Principales caractéristiques de la machine

- La machine d'emballage de chips utilise un contrôleur de température intelligent pour un contrôle précis de la température de coupe à chaud, garantissant une soudure lisse et esthétiquement agréable.

- Elle utilise également un mécanisme d'entraînement par servo-moteur dédié contrôlé par PLC pour la traction double-film et un mécanisme automatique de correction de position du film entraîné par moteur, ce qui maximise la précision, la fiabilité et l'intelligence du système de contrôle.

- Ensuite, la machine d'emballage de chips avec une configuration de dosage peut automatiquement accomplir tous les processus d'emballage de dosage, d'alimentation, de remplissage du sachet, d'inflation et de datation.

- Les formes de sachets peuvent être fabriquées selon les besoins du client. Nous proposons : sachets à joint 3 côtés, sachets à joint 4 côtés, sachets stand-up, sachets à poignée, sachets-pot, sachets à fermeture éclair, sachets composites et autres styles de sachets personnalisables.

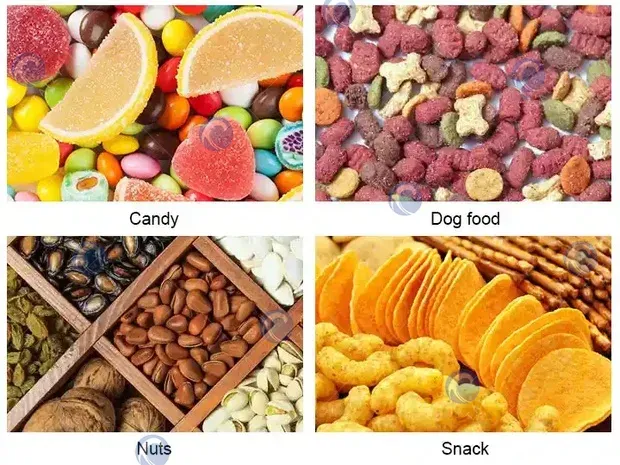

Application de la chips packaging machine

Taizy chips packaging machine convient pour emballer des matériaux fragiles exigeant une grande précision, tels que les aliments soufflés, le riz croustillant, la gelée, les bonbons, la pistache, les tranches de pomme, dumpling, le chocolat, la nourriture pour animaux, les petites pièces de quincaillerie, les médicaments, etc.

Elle peut automatiquement effectuer le remplissage, la pesée, la fabrication du sachet, le scellage et la coupe, ce qui en fait la machine préférée des usines de snacks, des usines d'emballage de pièces industrielles et des usines pharmaceutiques.

Pièces de la chips packaging machine

1. Machine d'emballage de base

Cette partie utilise un système servo, qui peut effectuer un positionnement de haute précision. La vitesse d'emballage, la longueur du sachet et la température du coupeur peuvent être modifiées via l'écran tactile PLC. De plus, la méthode de scellage et de coupe peut être sélectionnée comme coupe continue des sachets ou coupe d'un seul sachet.

En outre, la partie d'emballage est équipée d'une roue d'entraînement du film, qui est plus puissante que les machines ordinaires et peut supporter un poids d'emballage plus important (au moins 2kg). Il existe trois types de cette machine d'ensachage verticale : TZ-420, TZ-520, TZ-720.

| Type | TZ-420 | TZ-520 | TZ-720 |

| Longueur du sachet | 80-300mm | 80-400mm | 100-400mm |

| Largeur du sachet | 50-200mm | 80-250mm | 180-350mm |

| Largeur maximale du film en rouleau | 420mm | 520mm | 720mm |

| Vitesse d'emballage | 5-30 sacs/min | 5-50 sacs/min | 5-50 sacs/min |

| Plage de pesée | 5-1000ml | 3000ml(Max) | 6000ml(Max) |

| Consommation d'air | 0.65mpa | 0.65mpa | 0.65mpa |

| Consommation de gaz | 0,3 m³/min | 0,4 m³/min | 0,4 m³/min |

| Tension d'alimentation | 220V | 220V/50HZ | 220V/50HZ |

| Puissance | 2.2KW | / | 5KW |

| Dimensions | 1320mm*950mm*1360mm | 1150mm*1795mm*1650mm | 1780mm*1350mm*1950mm |

| Poids | 540Kg | 600Kg | / |

2. Doseuse combinée à 10 têtes

Cette peseuse est idéale pour peser des matériaux mélangés (tels que mélanges de noix et bonbons), en faisant un choix de premier plan pour les grandes usines de transformation alimentaire. Elle peut être intégrée à diverses machines d'emballage, y compris des machines d'emballage verticales, des alimentateurs de sachets et des remplisseuses.

La peseuse Taizy comporte dix godets, chacun en acier inoxydable, avec des paramètres configurables individuellement, permettant un mélange et une pesée précis avec une précision de ±0.3 à 1.5 g.

De plus, nous proposons également diverses solutions personnalisées. Vous pouvez choisir différents traitements de surface des godets (polissage, texturation, etc.) en fonction des caractéristiques du matériau (granulaire, poudreux, fragile, collant, etc.).

| Modèle | Doseuse combinée à 10 têtes |

| Capacité maximale de pesée | 1000g |

| Plage de pesée | 10 – 1000g |

| Précision de pesée | ±0.3 – 1.5g |

| Volume de pesée | Jusqu'à 3000cc |

| Vitesse maximale de pesée | Jusqu'à 60 pesées/min |

| Programmes prédéfinis | 50 types |

| Panneau de contrôle | Écran tactile 8.4 pouces (HMI) |

3. Élévateur à godets de type Z

This conveyor of the chips packaging machine is suitable for the vertical lifting of grain material in various industries, including corn, food, fodder, and the chemical industry. The lifting machine’s hopper is driven by chains to lift.

Furthermore, it’s also used for vertical feeding of grain or small block material, allowing for large lifting quantities and high heights with its automatic feed and shut-off functions.

| Hauteur de levage | 3m-10m |

| Vitesse de levage | 0-17m/min |

| Quantité de levage | 5.5 mètres cubes/heure |

| Puissance | 550w/380v |

Type : Il peut être personnalisé en acier au carbone, peint plastique, ou acier inoxydable. La partie en contact avec les aliments est faite de plastique de qualité alimentaire.

4. Trémie vibrante

Ce type d'alimentateur envoie le matériau du stockage au convoyeur de matière par vibration. Il présente une vitesse d'entraînement contrôlable, est construit en PVC, et est équipé de roues pour une mobilité aisée.

| Hauteur de levage | 0.8m-1.5m |

| Capacité de levage | 1 mètre cube/heure |

| Vitesse d'alimentation | 30m/min |

| Dimensions | 2110x340x500mm |

| Tension | 220V/45W |

Chips packaging machine’s bag sealing styles

Divers styles d'emballage peuvent être personnalisés : sachet boîte, sachet stand, sachet stand avec trou, sachet en bande, sachet en série, sachet oreiller avec trou, sachet à joint 3 côtés, etc.

Si vous avez d'autres styles d'emballage à personnaliser, veuillez me contacter pour connaître le service supplémentaire de personnalisation.

Comment choisir la bonne machine d'emballage pour snacks ?

Choosing a perfect chips packaging machine will improve your brand’s influence, because customers prefer good packaging bags when they make a decision. Here are some tips for you to choose the right snack packaging machine for your business.

- Choisissez la machine adaptée en fonction de vos produits. Comprenez bien votre matériau, notamment s'il est fragile, s'il doit être mélangé, et s'il doit être pesé avec précision.

- Determine the shape of the packaging bag, its width, length, and size. If you aren’t clear about it, please contact us. We will try our best to give you useful advice.

- Déterminez votre plage de production et le volume de production requis. Il est généralement recommandé d'acheter une machine d'environ 30% supérieure au volume de production réel dont vous avez besoin. Cela peut pleinement assurer que votre efficacité de travail n'est pas affectée par des facteurs externes.

Voici les paramètres complets de la machine entière.

| Modèle | TZ-420 | TZ-520 | TZ-720 | TZ-900 | TZ-1200 |

| Largeur du film | Max.420mm | Max.520mm | Max.720mm | Max.920mm | Max.1200mm |

| Longueur du sachet | 80-300mm | 80-350mm | 100-500mm | 100-600mm | 1000mm |

| Largeur du sachet | 60-200mm | 100-250mm | 180-350mm | 260-430mm | 290-580mm |

| Diamètre du film | Max.320mm | Max.320mm | Max.320mm | Max.400mm | Max.400mm |

| Vitesse d'emballage | 5-60P/min | 5-60P/min | 5-55P/min | 5-20P/min | 5-20P/min |

| Plage de pesée | 0.15-0.5L | 2L | 4L | 1-25L | 1.5-45L |

| Puissance (220v 50/60HZ) | 2KW | 3KW | 3KW | 4.5KW | 5KW |

| Dimensions | 1217mm*1015mm*1343mm | 1488mm*1080mm*1490mm | 1780mm*1350mm*2050mm | 2305mm*1685mm*2725mm | 2900mm*2050mm*3500mm |

If you don’t know which one is more suitable for your business, you can ask me for any advice about collecting the snack machin.