泰兹系列酱料灌装机特别适用于番茄酱、沙拉酱、花生酱等流动性糊状物。机器采用不锈钢制造,符合国际食品安全标准,适合各种规模的食品加工厂。

针对小规模生产,我们推出了每分钟8-25瓶的半自动灌装机,能灌装100-1000ml的产品。全自动灌装机可加入生产线,产量在每小时500-3000瓶,灌装范围为10-5000ml。

我们的酱料灌装机拥有CE和PVOC等国际认证。泰兹已帮助小工厂在尼日利亚、菲律宾、土耳其、智利等国家投资或收购大型生产线。如您在寻找可靠的包装解决方案,欢迎随时联系我们!

酱料瓶灌装机亮点

- 泰兹酱料灌装机采用304不锈钢制造。如有定制需求,我们也可以生产316不锈钢以满足您的高要求。

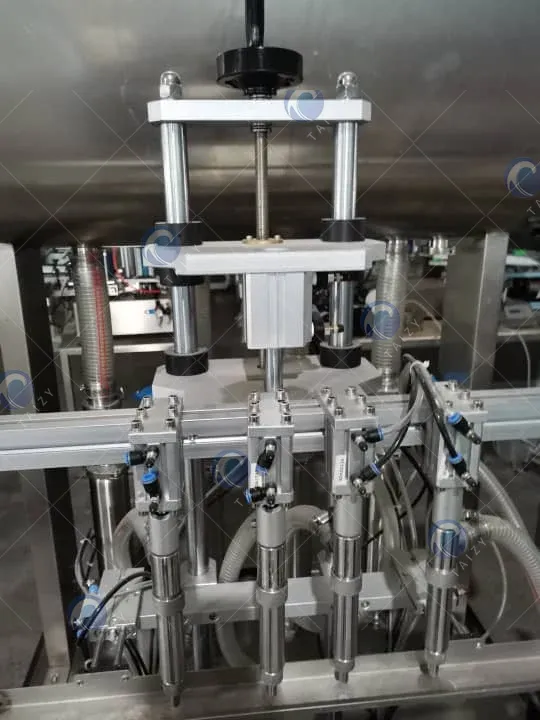

- 我们的机器配备调节阀,可通过调节气缸行程自动控制灌装量。

- 灌装头长度可根据不同产品容器的需求定制。具有精确的灌装容量,灌装后无滴漏或泄漏,保持工作台面清洁卫生。

两种类型的酱料灌装封口机

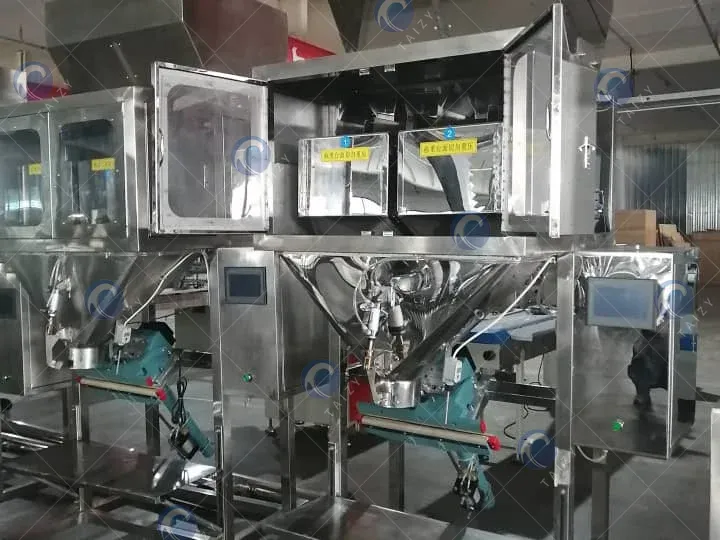

类型1:自动酱料灌装机

自动酱料瓶灌装机工作原理

配备全自动输送带和感应装置,此瓶装机具有自动盖帽/贴标等定制功能,完成灌装和包装全过程。

它主要由电动机控制,配备活塞泵以定量灌装酱料。只有一名员工即可控制整个机器。

自动酱料灌装机的参数

| 类型 | AT-SFGZ-L4 | AT-SFGZ-L6 | AT-SFGZ-L8 | AT-SFGZ-L12 | AT-SFGZ-L16 |

| 灌装喷嘴 | 4 | 6 | 8 | 12 | 16 |

| 测量范围 | 500-2000毫升 | 500-2000毫升 | 500-2000毫升 | 500-2000毫升 | 500-2000毫升 |

| 灌装精度 | ±1%(100毫升) | ±1%(100毫升) | ±1%(100毫升) | ±1%(100毫升) | ±1%(100毫升) |

| 生产能力(以500毫升为基准) | 500-1000 瓶/小时 | 800-1600 瓶/小时 | 1000-2000 瓶/小时 | 1500-3000 瓶/小时 | 2000-4000 瓶/小时 |

| 气源压力 | 0.5-0.7 MPa | 0.5-0.7 MPa | 0.5-0.7 MPa | 0.5-0.7 MPa | 0.5-0.7 MPa |

| 耗气量 | 20升/小时 | 30升/小时 | 40升/小时 | 60升/小时 | 100升/小时 |

| 总功率 | 2.0千瓦 | 2.0千瓦 | 2.0千瓦 | 2.0千瓦 | 2.0千瓦 |

| 重量 | 300 千克 | 400千克 | 500千克 | 700千克 | 900千克 |

| 整体尺寸 | 400*110*210厘米 | 400*110*230厘米 | 400*115*230厘米 | 600*100*230厘米 | 600*100*230厘米 |

花生酱灌装机成功案例

来自坦桑尼亚的客户加工销售花生酱、芝麻酱等坚果制品。为了扩大产能,他们从泰兹购买了一整套花生酱生产线。

在观察到生产线稳定运行后,他们决定扩大工厂产能,购买一条全自动酱料灌装线,以提高包装效率并降低人工成本。

“我们首先从泰兹购买了花生酱加工线,运行非常顺利。这也是我们再次选择他们的原因。现在整个生产流程——从烘焙到灌装——实现了全自动化。生产效率翻倍!”

类型2:手动糊状物灌装机

半自动糊状物灌装机工作原理

活塞注射由脚踏开关或按钮激活,需人工放置瓶子或罐子。整体控制简单,适合中小型作坊。

手动糊状物灌装机参数

| 模型 | TZ-G1 | TZ-G2 |

| 电源 | 220/110 V 50/60 Hz | 220/110 V 50/60 Hz |

| 灌装范围 | 100-1000 ml | 100-1000 ml |

| 气压 | 0.4-0.6 MPa | 0.4-0.6 MPa |

| 包装速度 | 8-25瓶/分钟 | 20-60瓶/分钟 |

| 重量 | 20 kg | / |

瓶装机成功案例

这位来自厄瓜多尔的客户经营一个小型果酱制作车间,主要向当地超市和电子商务平台供应天然手工果酱。

他们之前采用手工包装,无法实现精确生产。为了减少浪费,确保包装均匀美观,客户寻求一种高效、卫生、精确的半自动酱料灌装机,适用于高粘度果酱。

“我们用这台机器灌装不同口味的果酱——芒果、菠萝和番石榴。灌装效果非常好,贴标机让我们的瓶子看起来更专业。自从改善包装后,我们的销售额增加了!”

自动与半自动糊状物灌装机的区别

| 型号类型 | 手动糊状物灌装机 | 自动酱料灌装机 |

| 操作 | 需要手动放瓶 | 全自动流程,包括瓶子送料、灌装、盖帽和贴标 |

| 产量 | 每小时300–800瓶 | 每小时2000–6000瓶 |

| 价格 | 成本低,经济实惠 | 投资较高但效率更大 |

| 应用场景 | 非常适合创业、小型作坊和手工产品 | 适用于中大型工厂和连续生产线 |

泰兹酱料灌装机的应用

该机器不仅可以灌装瓶装(如番茄酱、辣椒酱、沙拉酱、蜂蜜等流体或半流体产品),还可以灌装(花生酱、芝麻酱、果酱等高粘度材料)。

因此,我们的酱料灌装机在许多食品生产和加工行业中非常重要。大型调味品工厂、坚果酱生产商以及餐饮和食品加工行业都将使用这些全自动灌装机以扩大产能。

虽然小型手工作坊也会购买半自动灌装机以提高生产效率,但此款酱料灌装机成本低廉,占用空间小,非常适合预算有限的创业品牌。

如何为您的业务选择合适的酱料灌装机?

- 根据您的生产规模:小批量可使用半自动型号,大规模生产应选择全自动型号。

- 投资预算也是关键因素:半自动型号更经济,而全自动型号从长远来看更具成本效益。

- 人工成本:如果人工成本高,全自动机器可以节省资金,而半自动机器适合人工成本较低的地区。

- 技术要求:需考虑自动化程度、清洁便利性和售后支持。

联系我们获取免费配额和生产清单!

如果您在选择可靠的公司帮助解决包装方案方面犹豫不决,泰兹愿为您提供最优质的服务。

- 我们拥有源头工厂,为您提供最实惠的价格和最优质的产品。

- 我们拥有最完整的出口经验,经验丰富的销售团队可以帮助您解决所有与机器相关的问题。

- 我们拥有最透明的流程,从机器生产到交付。每一步都经过充分协商,以满足您的所有需求。

立即联系我们获取最新报价和更详细的产品信息!

除了我们的酱料灌装机外,我们还提供: