饮料公司如何升级其生产流程,在选择机械供应商时应考虑哪些要点?

我们在波兰的一位客户遇到一个问题:如何找到一家值得信赖的制造商,提供高质量的水袋包装机,预算内且提供可靠的售后服务。这是他们的项目目标。

客户公司信息

我们的波兰客户是一家位于波兰中部的中型饮料公司,专注于瓶装水和饮料。随着波兰对方便、卫生和环保包装的需求不断增长,该公司希望提高生产效率,同时确保食品安全。

他正在寻找一种自动化解决方案,能够处理中小批量,保持灭菌标准,并清晰打印生产信息。鉴于欧洲标准电压为230V/50Hz,单相,我们还要求使用E型插头以适应本地电气插座。

最终订单确认

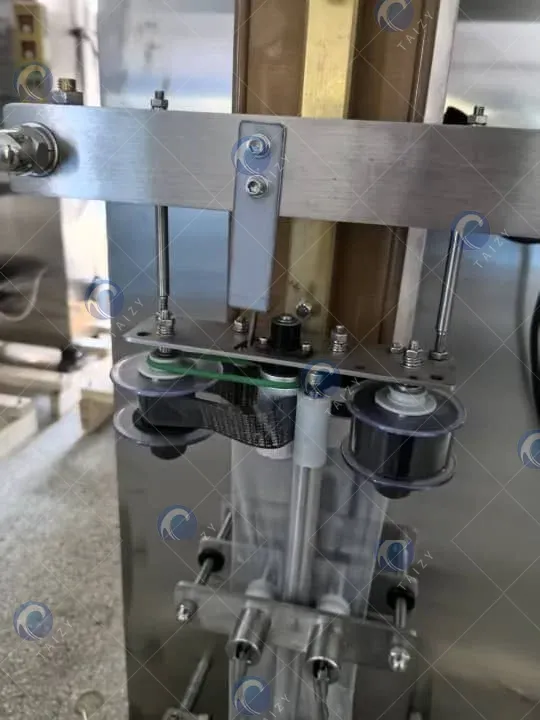

最初,客户咨询了全自动和半自动液体包装机。在与公司讨论后,为确保在预算内获得最佳效果,他们决定购买一台单一机器,最终选择了TZ-2000液体袋装机。

| 机器 | 参数 |

水袋包装机 | 袋子尺寸:长度50–250毫米,宽度40–175毫米 包装薄膜宽度:100–380毫米 包装速度:每小时1100–1300袋 计量范围:每袋200–1000毫升 电源:2.5千瓦,230V,50Hz,单相,E型插头 附加功能:内置薄膜灭菌系统 |

客户强调包装效率的重要性,并指出紫外线灯灭菌卷膜、E型插头更换和日期编码等功能对其饮料生产和符合波兰食品安全法规至关重要。

液体包装机的交付和反馈

订单包括额外的定制服务,并经过交付前的测试。我们的技术团队与客户保持持续沟通,确保进展顺利,交付和安装顺利完成。

安装后,这台液体袋包装机显著提高了客户的生产线效率:

- 每小时1100-1300袋,增加产量而无需额外人力。

- 内置灭菌系统确保产品安全并延长保质期。

- 双色带编码机确保符合食品追溯标准。

- 可调节的袋子尺寸和灌装容量适应各种产品规格。

客户反馈新系统不仅减少了人工,还帮助他们满足本地零售商和分销商不断增长的需求。

联系我们,提供一站式机器供应

本案例展示了TZ-2000水袋包装机如何帮助波兰饮料生产商提升产量、改善食品安全和提高运营效率。

对于寻求可靠、高效、卫生包装解决方案的企业,泰兹的机器提供符合欧洲标准的交钥匙解决方案。我们的机器已获得CE认证,并提供全面的售后支持,让您无后顾之忧。